Well, after a post trip inspection some time ago I found an issue that required attention. Evidently when I made my lower hose fitting on the motor it was too close to the frame rail. This situaton was made worse when I built my transmission crossmember and raised the rear of the engine up a fuzz (scientific measurement right there). I believe that this, coupled with everything settling in created the condition that left the lower hose resting on the frame rail. It was not a situation that required immediate attention, but it also was not going to provide a very good service life if it was not addressed.

Sounds like fun. Let's go!!

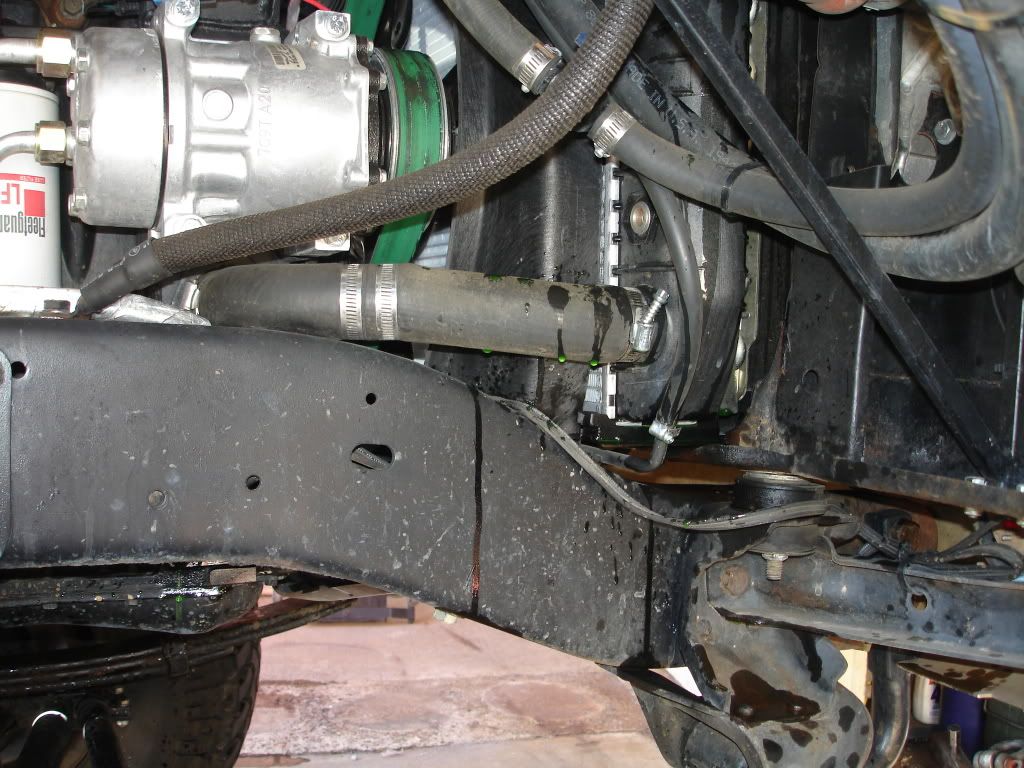

This is what it looked like without the inner fenderwell:

This is what was happening to the hose assembly:

There is no real damage per se, but my concern was that dirt and stones would get trapped between the hose an frame rail and work holes into the hose. If you look close you can see some starting already.

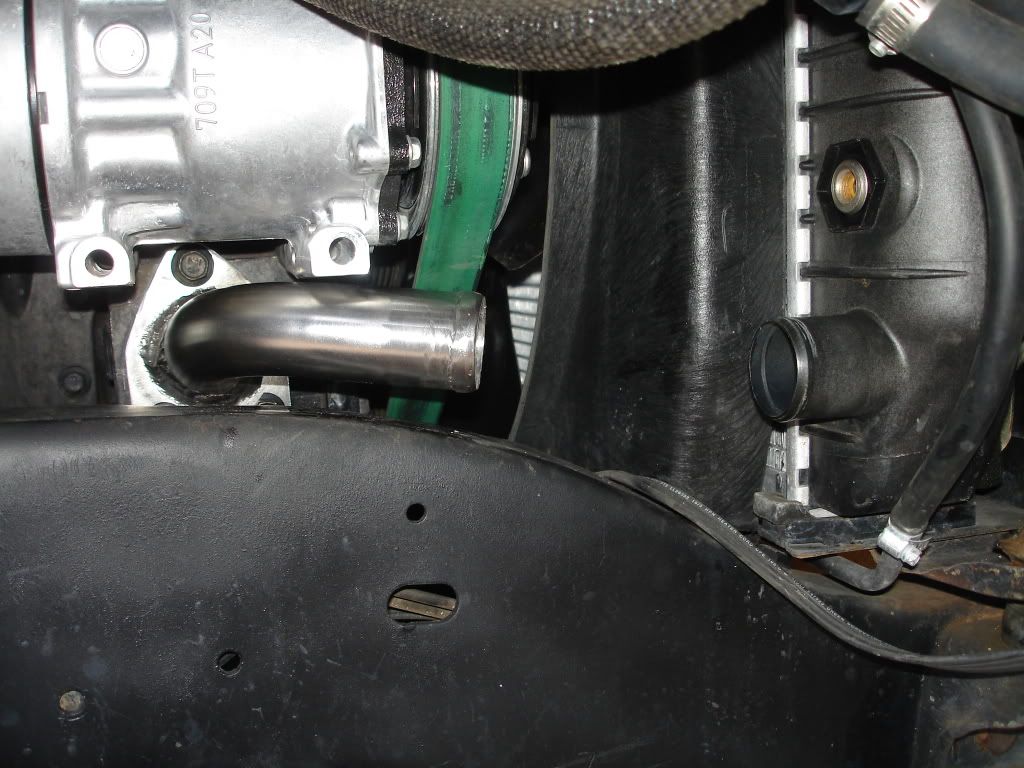

Ok, so that's great, but what to do. There is not much room there with the frame rail, a/c compressor, inner fenderwell and belt right there. I figured pipe is smaller in o.d. than hose, but not flexible. Hmm, this could work. I bought a mandrel u-bend from Lefthander Chassis.

I pulled my water inlet fitting off the motor and ground out my previous hose fitting. There is a stub of .188 wall tubing welded into the flange I made that I put the thinner tubing that forms the hose fitting into. It makes the whole thing way bunches stronger (scientific quantity).

So, I got to trying to figure out an angle for the nipple, a direction to point it, an elevation that will clear everything, but still leave me with the longest hose possible. I got it figured out and welded it up and also welded a hose retention bead on the end of it. I think I ended up with everything I needed, but the lower hose is shorter than I would have liked.

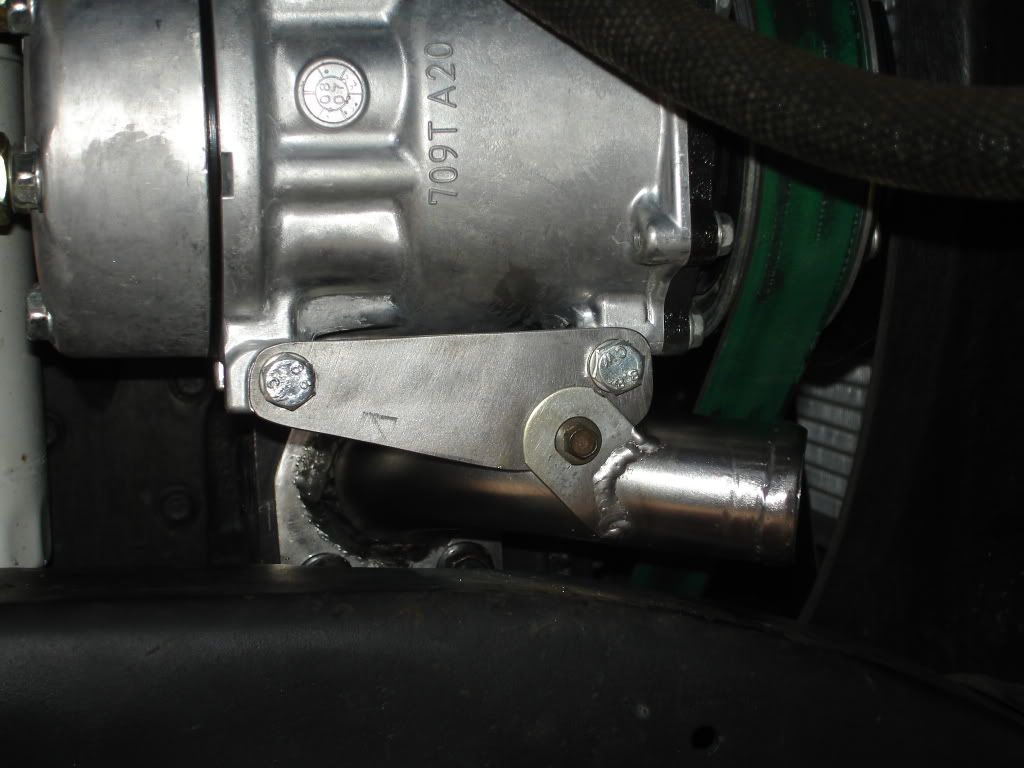

So, with such a short hose, I was a bit nervous about the tubing that makes the hose nipple. Even though it is piloted into the .188 wall tube that is in the 3/8" plate that forms the flange, I was still a bit apprehensive about the possibility of a problem so I figured out a little supoport bracket that sits out toward the hose end.

I blew a coat of paint on it and put it back together. It clears everything very well and seems to be fine so far with the shorter hose. While I had the system down for modification, I decided to do a coolant service. I drained the green coolant that I had in there and went back in with the red Rotella ELC (Extended Life Coolant). I flushed the green out and everything in the cooling system looked brand new still. My only issue with the old coolant was it started smelling funky. Not terrible funky, just funky. I absolutely despise red coolant for some reason, but this is the stuff that the truck dealerships that I deal with use, so if it is good enough for them, I decided to give it a try. We'll see.