Next up is making the pillar extensions.......

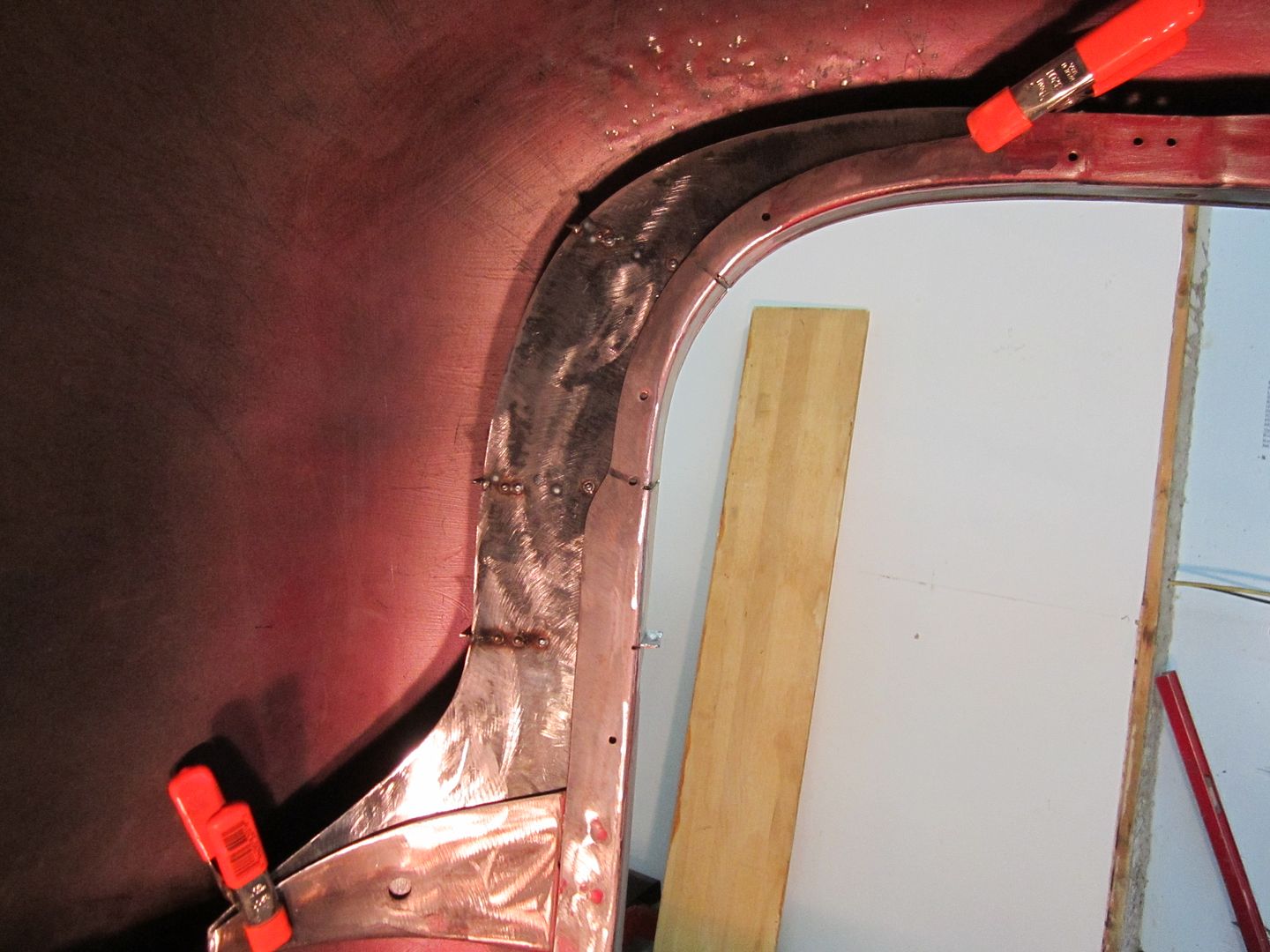

I just cut them out of 18 guage and spent some time bending, hammering, and massaging them to fit the contour of the factory pillar. As mentioned previously the plan is to tuck them behind the pillar and weld along the entire length of the seem and also do some plug welds for additional strength.

[/URL]

[/URL]

Once the extensions where made I had to figure out a way to keep them from folding forward in the event of an accident. The only solution I could come up with was to add some structural ribbing on the back side of the pillar welded to the extension at a 90 degrees. The biggest problem would be the lack of space behind the pillar extension as there is barely enough room to get your hand behind , much less the welding gun. So here's what I did. First I did 3 plunge cuts on the inside of the door jam. This would allow me to slide the ribs in from the front side. I made the ribs slightly longer then I needed them this would allow me to get one spot weld on the far back end of the rib to hold in in place. I did the ribbing one at a time so I could keep going back to the truck to make sure I could still get the pillar back in place and not have the ribs move.

[/URL]

[/URL]

[/URL]

to further hold the ribbing in place I spot welded through the pillar to the ribbing. This was crucial as I needed all the ribbing to stay in place so that it wouldn't move around when I took the pillar back out for final welding of the ribs

[/URL]

Once I had the pillar and the ribbing back out I could finish welding the ribs in place on the bench.

[/URL]

After a looooong day of work, I had 2 matching pillar extensions complete with some support ribbing in hopes of keeping the pillar from folding forward.

[/URL]

After the ribbing was complete I trimmed the front side of the ribbing off keeping only about a 1/4" protruding through the inside front of the door jam. This will give me enough material to weld the ribbing fast to the inside of the jam when I close up the access holes, thus (hopefully) giving me added strength to the webbing.

[/URL]