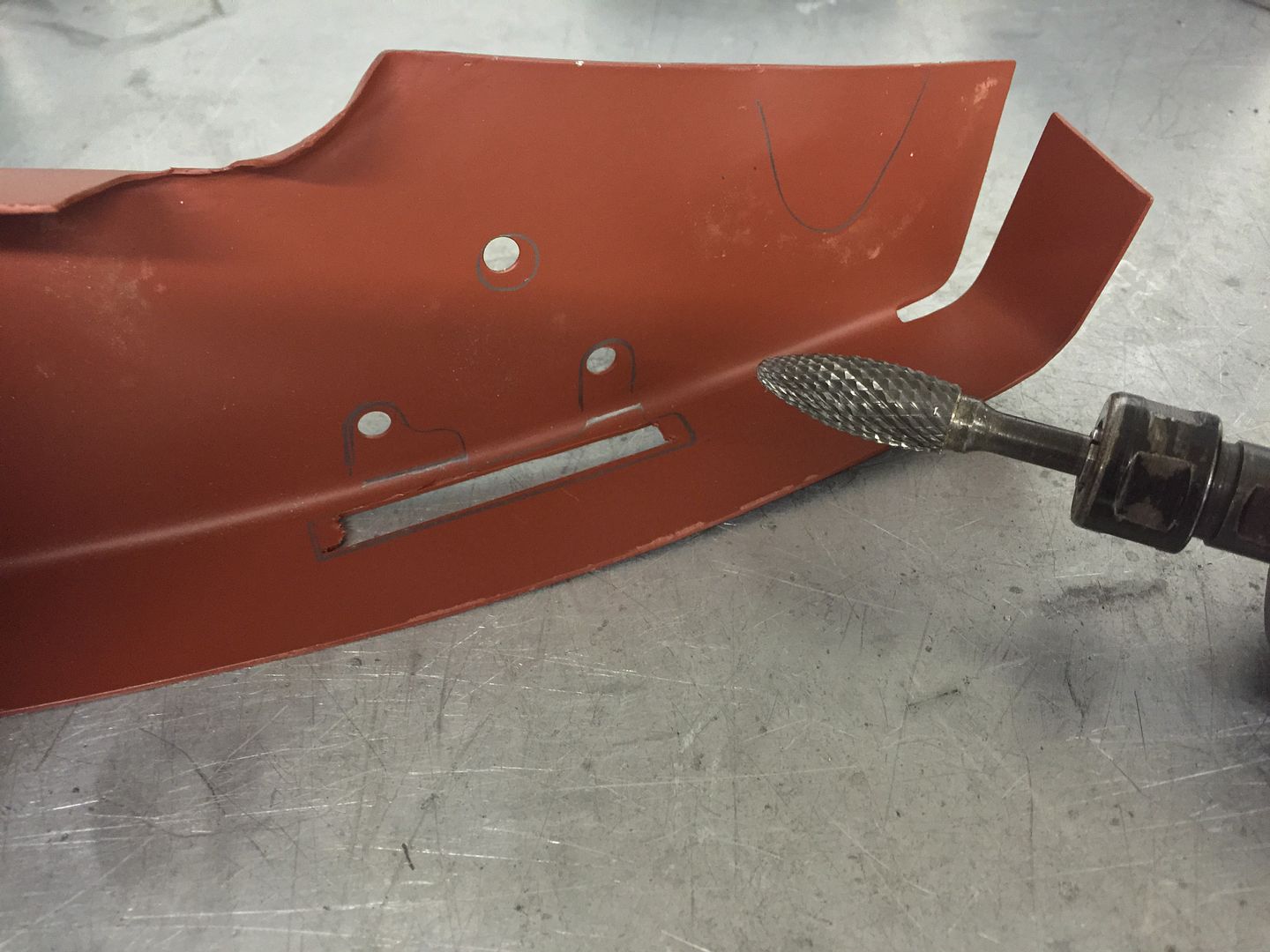

I have the pans and inner rocker welded in, so I moved to finishing the A-pillar bottom. I tacked the inner A-pillar in place and stuck the outer skin over it to mark the size/location of the hinge holes. Used a carbide burr to open up the holes almost all the way, then a step-bit to get to the final size which also cleans up the edges.

Squared up the other opening with a rectangle file.

Inner A-pillar welded, smoothed up, and mopped with epoxy.

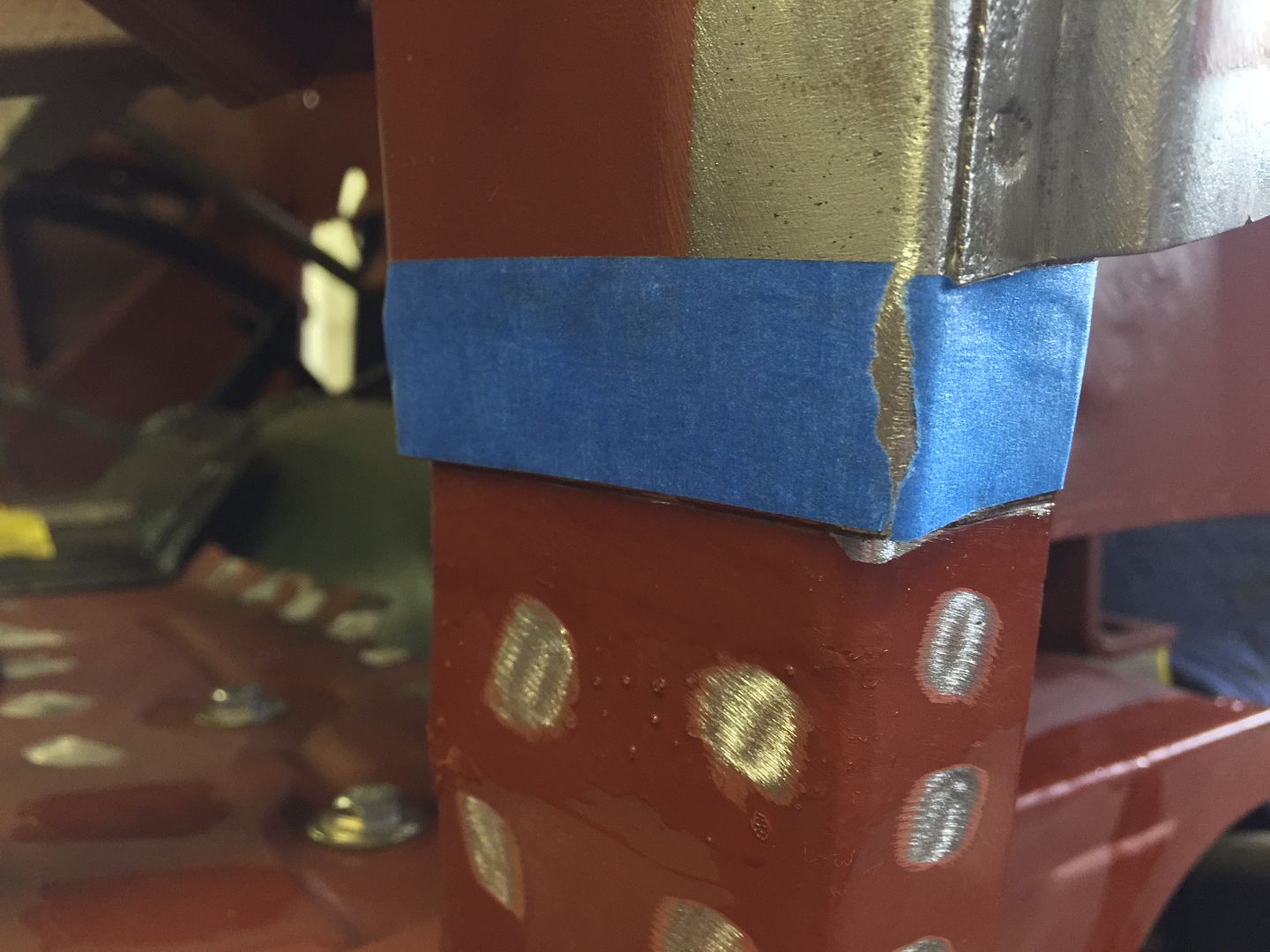

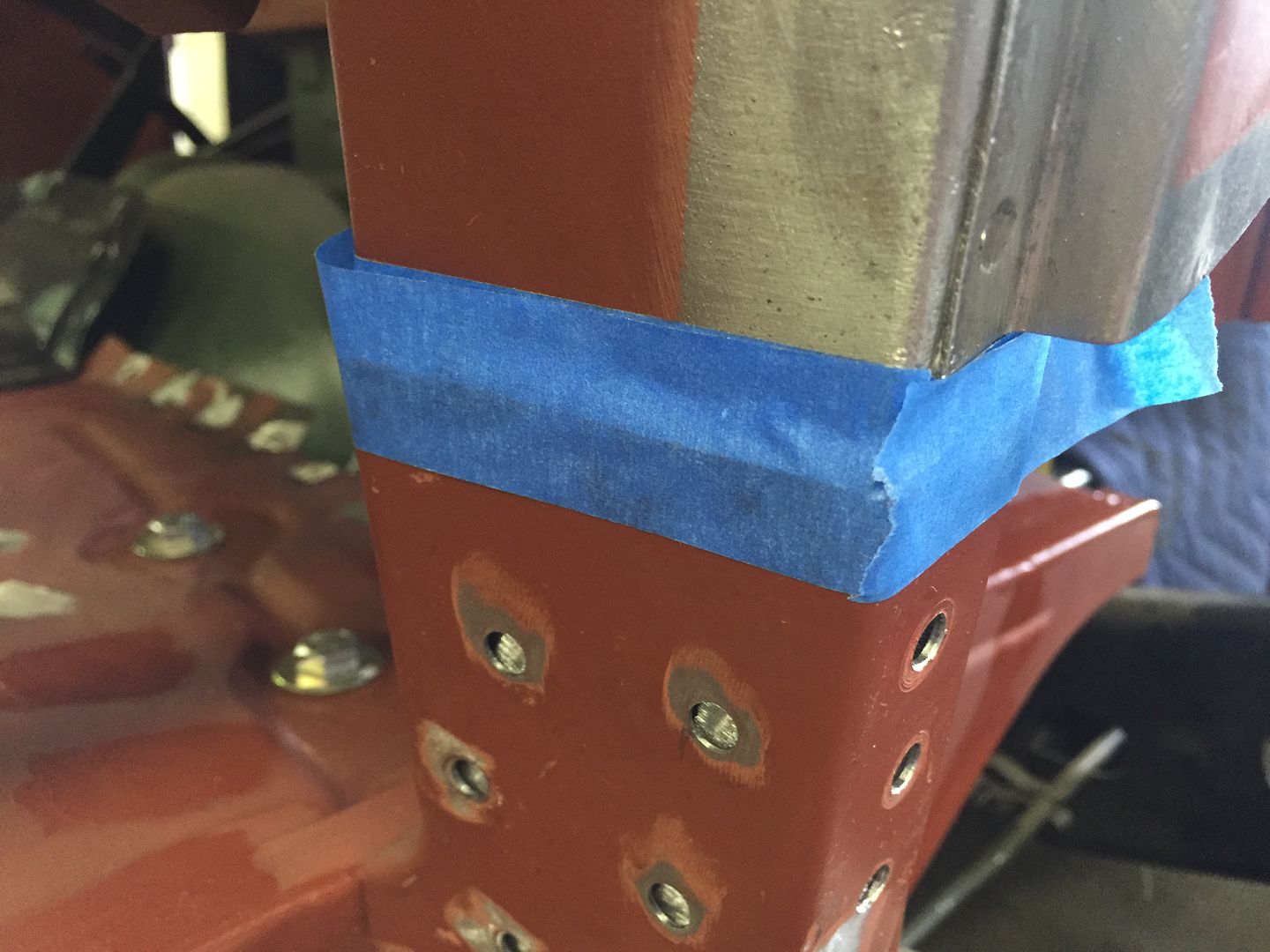

Used tape to locate the edge of the outer skin, this will help with trimming the outer layer to size without having too big of a gap.

Outer skin stuck in place, another layer of tape placed over the first piece. The bottom edge of the tape will be the cut line.

Outer skin welded in place, welds smoothed.

Inner A-pillar brace welded in.

Inner cavity mopped with epoxy after welding.

And a "work in progress" shot. Currently working on getting the outer rocker ready for welding.