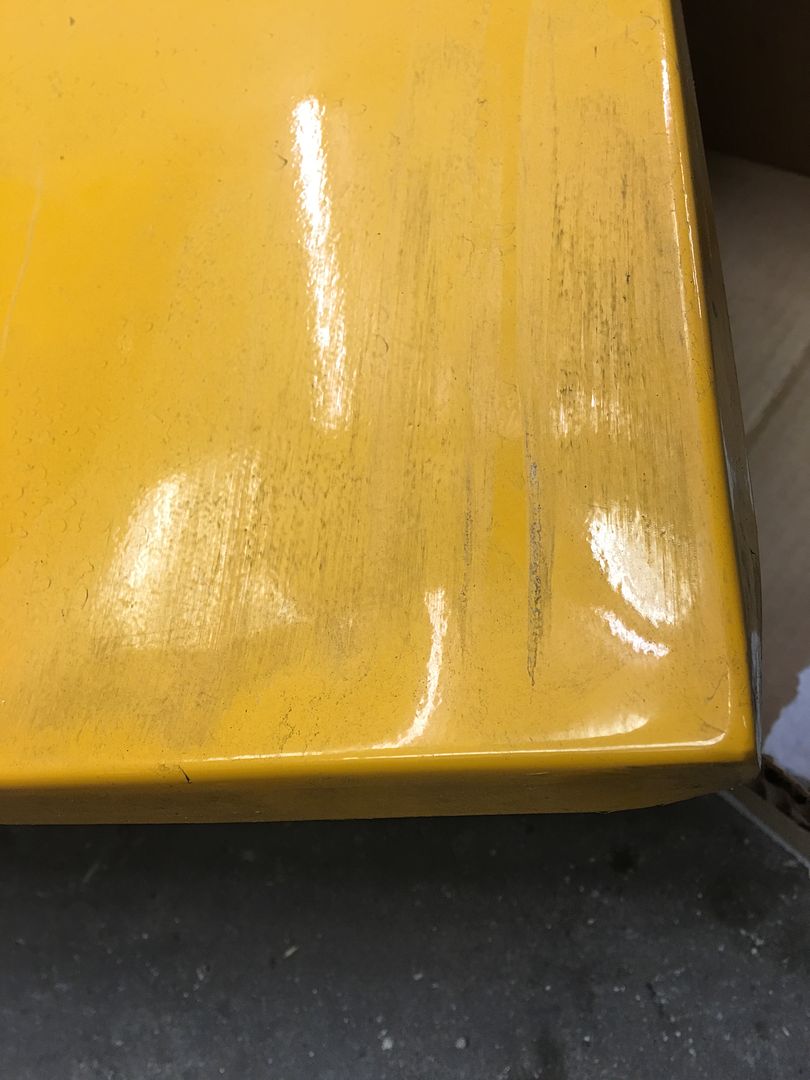

Well here's the saga of the latest bus repair. It seems a new driver at a local high school was attempting to back out of a parking space and missed the BIG YELLOW vehicle already occupying where he intended to move. Maybe they should change the color of those buses so you can see them coming.

Note door gap closed up here...

So from the onset, it looks like we need one new door, a filler panel, some "adjustments" to a couple door frames, painting and buffing.

Filler panel was fabricated out of 18 ga cold rolled steel, abraded with the DA, and prepped for SPI epoxy primer..

New door and filler panel have been sprayed with SPI epoxy, here shown after blocking with 400 grit..

New hardware getting prepped for painting...

Stainless hardware is used to stave off the rust issues. The bright polished finish does not provide good adhesion for a paint finish. Additionally, we've found that excessive paint build on these promotes cracking/chipping of the paint while driving them in during installation.. So to minimize the build on the hardware, we have eliminated primer on these parts. We media blast with 80 grit garnet media, blow off with air, and they get yellow urethane directly on the abraded fasteners. This method has shown to work well with NO chipping...

Dis-assembly..

The filler panel is actually sandwiched between two flanges at each luggage box, so the bus needed to be jacked up about 8" where the filler panel could be slid in place from the bottom, and bus dropped back down to level before attachment so we didn't have any twist in the boxes.

All door gaps addressed, painting, touch-ups, and buffing complete, ready for school!