Quite a bit has happened since the last update. I have been chasing an intermittent bump-induced driveshaft vibration for several months. Despite rebuilding the CV and replacing the output bearings in the t-case the vibration persists. :gaah: I will get it figured out one of these days.

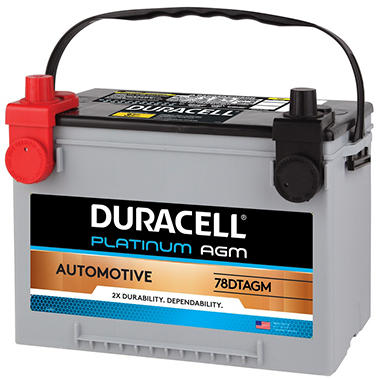

My batteries finally went Tango Uniform I was originally set on running a pair of group 24 flooded deep cycles because, frankly, I believe properly maintained QUALITY deep cycles will outlast AGMs. However, that plan got thwarted when I discovered that Sam's Club had group 34/78 Deka AGMs (labeled Duracell) for only $105 during a Christmas sale!

Sign me up on that deal! I eventualy plan on moving the batteries out of the engine bay and into the rear of the truck, so hopefully getting them out of the engine bay heat will increase their lifespan. When I do that I will make the battery boxes capable of accepting group 31's.

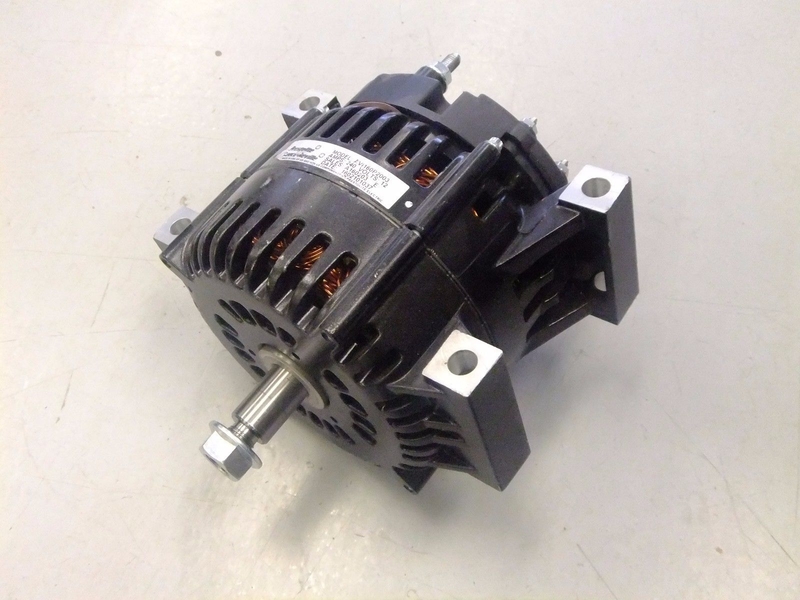

Not long after that my third Autozone alternator decided to windmill the pulley and spit the belt off. Swell. At this point my option was to fix the pulley and keep running the Zoner alternator, or put this in it's place:

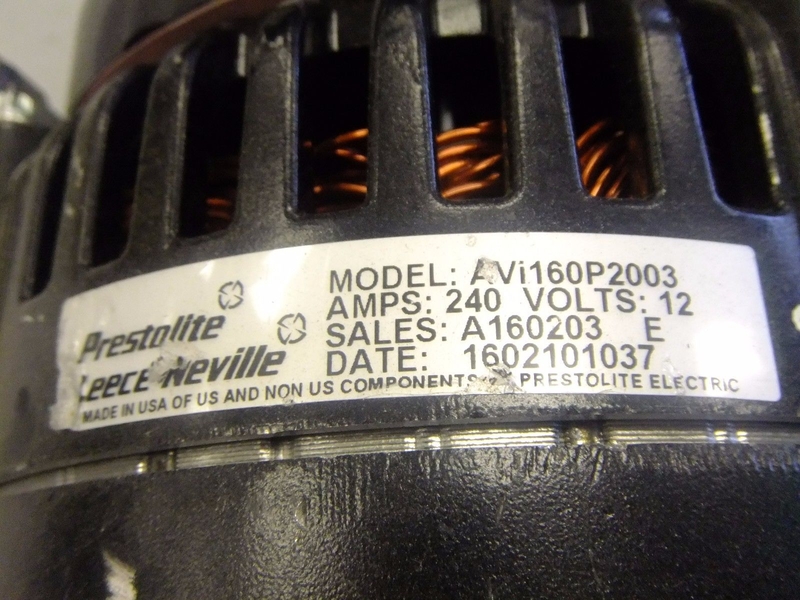

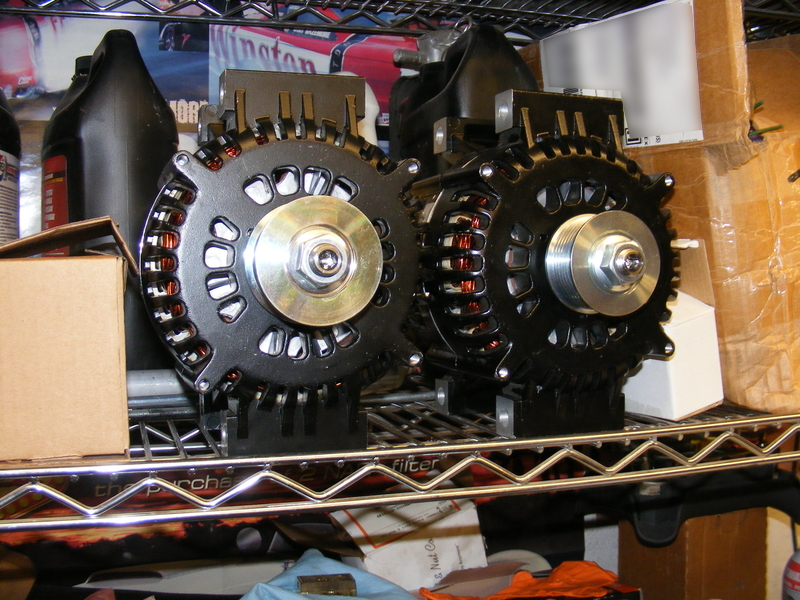

I scored a pair of these off of Ebay for $165 each. Normally, these are $525 alternators, but these had been dropped and had broken back covers and some dings, hence the discount.

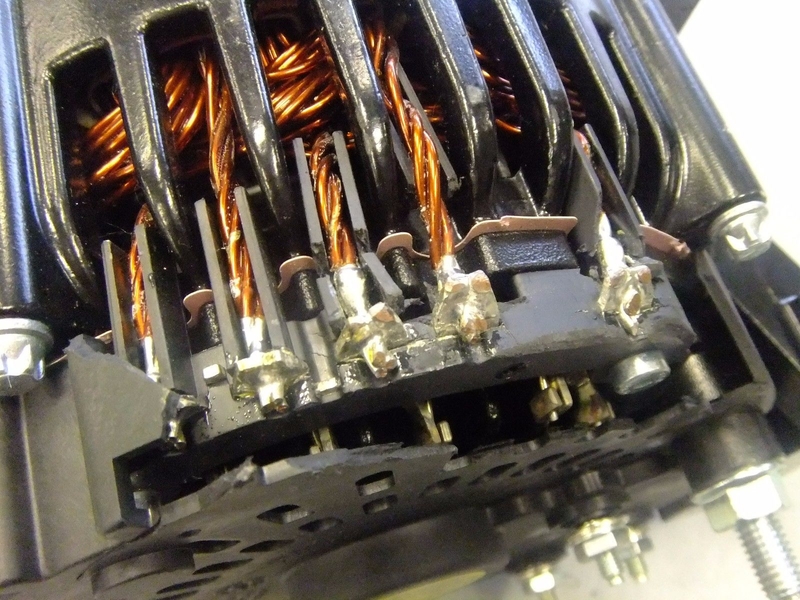

$525 you say?!?! Why so expensive? Simple answer:

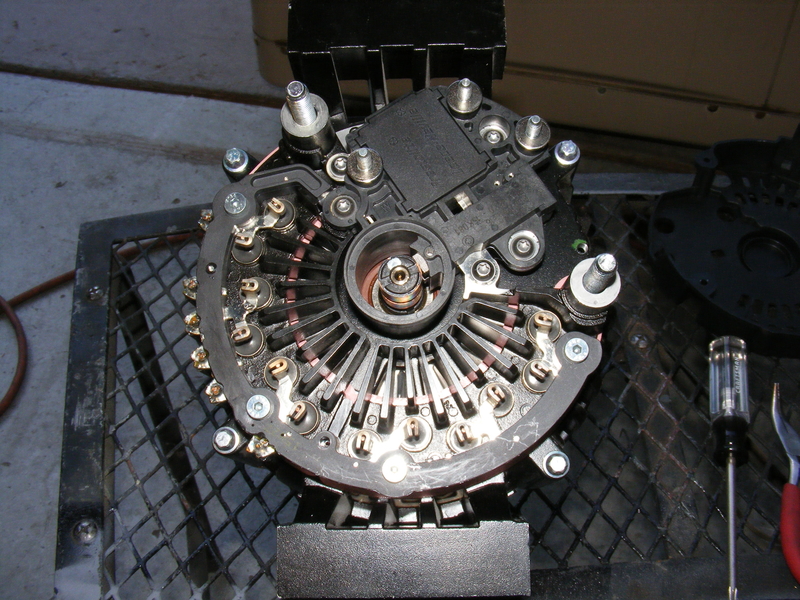

This alternator can crank out 240A CONTINUOUSLY. And they are made in USA. Unlike mere mortal alternators that have six rectifier diodes that are heat-sinked to the case, these bad boys sport 12 rectifiers in their own heat sink, which is still mounted to the case for further head sinking.It also has dual fans:

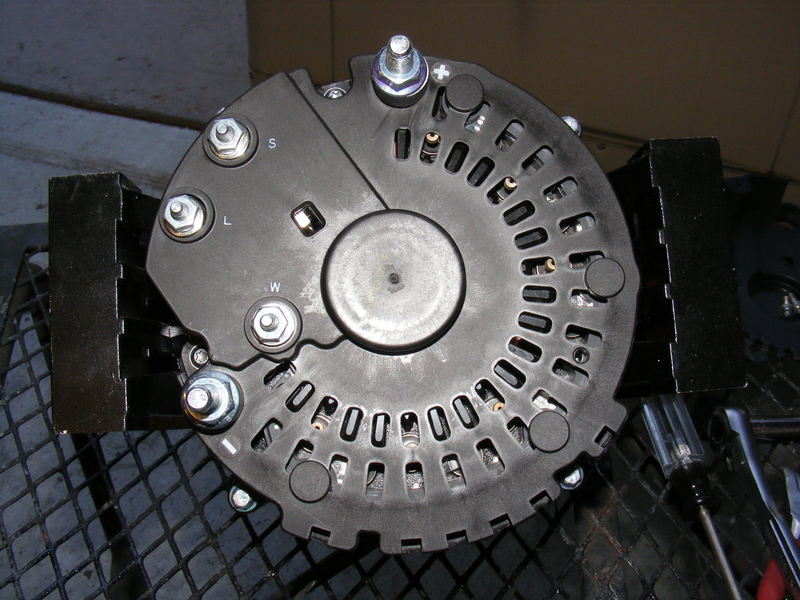

I ordered new rear covers for them, as well as an 8 rib pulley and a 7 rib pulley. They 8 rib pulley is for mine, while the 7 rib pulley is destined for Todd's Jeep. These alternators have 7/8" shafts, and it seems 6 rib alternators are not made for that size shaft, so the 7 rib jobbie will be used on the LS motor with it's 6 rib belt. Here they are, ready to go:

10 hours of machining and wrenching later, I ended up with this:

What is not noticeable in the above pic is that the AC hoses and lines are gone. This was pre-planned even before the alternator debacle. I evacuated the refrigerant and capped the compressor, condenser, and receiver. In the next few days I will remove the glower/evaporator box from under the hood and the HVAC box from under the dash. This will get replaced by a unit that fits entirely under the dash. The purpose of removing the factory HVAC stuff is to make the room needed to fit the HE351VE variable geometry turbo that I have acquired

Not to mention I have always disliked that crap cluttering the engine bay. It will also make room for another item I have just ordered, but I am keeping hush-hush for now