Thanks for the positive comments on the build. Well over my foot injury now and back to the routine problems of just being old.

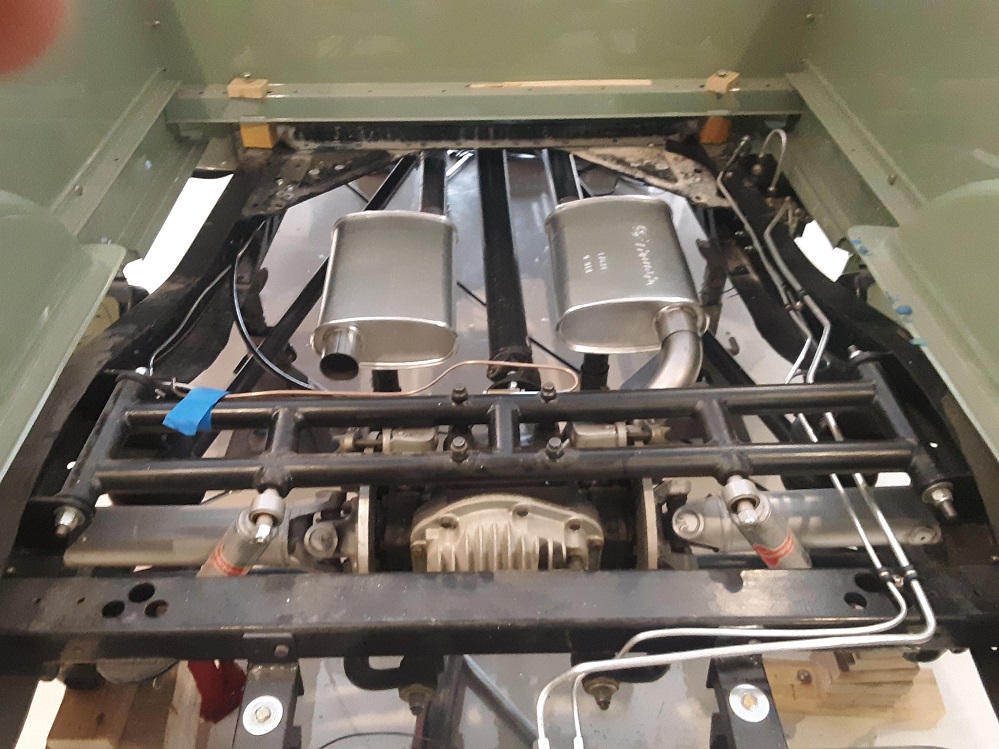

Worked on the exhaust system yesterday. My order from Jeg's came yesterday with the Thrush mufflers. Built the other side from the header flange to the muffler. I offset one side of the exhaust so it straddles he offset in the driveshaft - about an inch I'd guess. One muffler is higher than the other in this foto- need to put a 2x4 under it to level it up

I'm planning to run the exhaust under the IRS. I see a lot of recent production cars do this and don't seem to have any problem with scrubbing the exhaust, so I'm going to give it a try. Once I get it past the diff, it'll sweep up and follow the frame. For now I'm just going to try the Thrush mufflers alone, but I'm going to leave enough room for a resonator just before the dump at the roll pan, just in case I want to quiet it down or need to take some drone out.

I tucked the exhaust system pretty tight to the frame and couldn't figure how I'd put an X-pipe in there, much less how to get it out if I need to remove the exhaust. So my solution is to go with an H-pipe instead, but I had to put a 'belly' in it to clear the transmission. The drop down of the H-pipe is less than the transmission rear cross member so there won't be any scrub issues. I am a little worried about exhaust condensate running into the H-pipe though. Here's the pieces for the H-pipe cut and ready to fit and tack together (it is upside down in this foto). I put a V-band clamp in the middle so I can take it in and out without removing the transmission and rear suspension cross-member. Just being held together here with gravity and a little help from a radiator hose clamp.

The two pipes laying on the bench are scraps sitting the same distance apart as the pipes under the truck so I could mock it up without having to wiggle under the truck for trial fits (If I ever have two nickles to rub together I'm gonna buy a two post lift). My tube fish-mouth tube cutter won't handle 2.5" tube, so I found a way to make a paper template on the web. Simply printed it out, taped it to the tube and cut the fish-mouth on the band saw. I wouldn't want to do a lot of them this way, but not too bad for just a couple.

Just for fun, here's the other car project I'm working on - '53 MG TD. I made new door skins and replaced some of the rotted wood in the doors last year. I rebuilt the hinges and one door fit the aperture perfect, but the driver's door rubs pretty hard in the corner. To fix it, I had to take the skin back off the door and move the wood around so it fits the aperture, then re-install the skin and trim the metal for the changes I made in the wood. This thing is built pretty much how they built horse-drawn coach carriages and very early automobiles. Even my old '29 Ford didn't have this much wood.

That's about it for now,

Phil

Phil