Quote:

Originally Posted by Richard2112

Really impressive thread. Great pics, lots of info, good work. Cool projects in the works. Really like the barn in the pics at the start of the thread.

|

Thanks! Its starting to come together, When I ever find the time I need to square up the barn it has a slight lean to it. I need to square it up and brace it. I also need to replace one of the main beams as well do to termite damage.

I have been slacking on uploads.

I ended up making a set of Diy led turn signals. I needed a way to make more room behind the turn signal housings to clear my cummins intercooler. The intercooler mounting brackets where hitting the turn signal bulb sockets. At first I tried using a set of sockets from a 1990s mazda that I had laying around. They were a little more low profile but they were still too long.

I ended up ordering a set of cheap led Surface Mount Oval Amber Turn Signal lights for a truck or trailer.

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

IMAG3010

IMAG3010 by

jarrod vanwinkle, on Flickr

IMAG3011

IMAG3011 by

jarrod vanwinkle, on Flickr

I started bending the black housing away from the clear lense with my hands, the lense if just glued on. Once it started to separate I went in with a flat head and popped the lense off.

IMAG3022

IMAG3022 by

jarrod vanwinkle, on Flickr

I then trimmed the black bousing to fit in the turn signals.

IMAG3013

IMAG3013 by

jarrod vanwinkle, on Flickr

I ended up putting the turn signal lense from the c30 in the mill and milled out a little bit of the lense to fit the leds as the two outer leds are just a little two wide to fit in the lense. You could do the same with a dremel or a grinder.

IMAG3012

IMAG3012 by

jarrod vanwinkle, on Flickr

Its sits flush in the lense now.

IMAG3014

IMAG3014 by

jarrod vanwinkle, on Flickr

IMAG3015

IMAG3015 by

jarrod vanwinkle, on Flickr

Testing the lights.

IMAG3016

IMAG3016 by

jarrod vanwinkle, on Flickr

IMAG3017

IMAG3017 by

jarrod vanwinkle, on Flickr

high or flash

IMAG3019

IMAG3019 by

jarrod vanwinkle, on Flickr

low or running lights

IMAG3020

IMAG3020 by

jarrod vanwinkle, on Flickr

I trimmed the second one a little bit better.

IMAG3023

IMAG3023 by

jarrod vanwinkle, on Flickr

IMAG3025

IMAG3025 by

jarrod vanwinkle, on Flickr

I'm just going to connect my stock connecter to the lights. you can see how much room I have now the stock bulb sockets stuck out like a inch and a half.

IMAG3027

IMAG3027 by

jarrod vanwinkle, on Flickr

If you wanted to make it plug and play you could get a set of 2057 or 1157 Male Head Extension Connector Plug Socket with Wire Harness and make them plug and play.

https://www.amazon.com/Redcolourful-...omotive&sr=1-1

I plan on getting a set of new lenses as mine are the originals and one is cracked. After I do that I plan on apoxing them in to make them a bit more waterproof. At the moment they just have tape on the back. They still use the stock seal but mine lenses had dirt in them when I took them off.

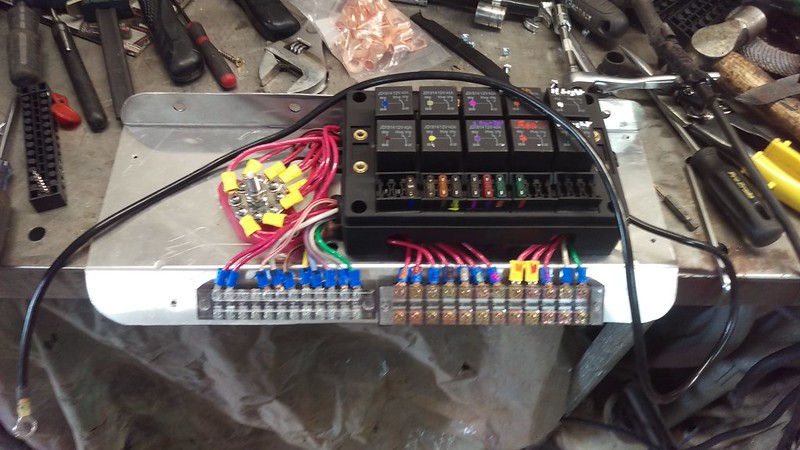

I also started on my engine bay harness.

The new lay out

cummins c30 alt wiring

cummins c30 alt wiring by

jarrod vanwinkle, on Flickr

Stock

stock v8 c30 engine bay wiring

stock v8 c30 engine bay wiring by

jarrod vanwinkle, on Flickr

I wired up a Dedicated under hood relay box. It houses 10 40 amp relays and 15 blade fuses. I need to add a lot of accessories and do a few upgrades.

Things I am adding to the box

1. Electric Fan 1

2. Electric Fan 2

3. Headlight high

4. Headlight Low

5. Starter

6. Fog lights

7. Flat bed work lights

8. Headache rack bed light bar

9. Roof rack work lights

10. Open for now

Things I am going to add to the mounting panel I built to mount the box.

4 heavy duty 100 amp relays 2 for the grid heater and 2 for my onboard air.

One 200 amp relay for the switched power items.

Finished up the wiring all the main power wire are 12 gauge, except the two fan wires are 10 gauge. The trigger wires and ground wires are 18 gauge.

IMAG2986

IMAG2986 by

jarrod vanwinkle, on Flickr

IMAG2996

IMAG2996 by

jarrod vanwinkle, on Flickr

IMAG2997

IMAG2997 by

jarrod vanwinkle, on Flickr

I used nutserts on the fender

IMAG2998

IMAG2998 by

jarrod vanwinkle, on Flickr

IMAG2999

IMAG2999 by

jarrod vanwinkle, on Flickr

A little intermission gardon up date

A few weeks ago we got a load of fill dirt for the raised beds

Screensho1

Screensho1 by

jarrod vanwinkle, on Flickr

IMG_18601

IMG_18601 by

jarrod vanwinkle, on Flickr

it took 7 loads for each bed of the fill dirt.

IMAG2958

IMAG2958 by

jarrod vanwinkle, on Flickr

IMAG2961

IMAG2961 by

jarrod vanwinkle, on Flickr

IMAG2962

IMAG2962 by

jarrod vanwinkle, on Flickr

IMAG2963

IMAG2963 by

jarrod vanwinkle, on Flickr

IMAG2964

IMAG2964 by

jarrod vanwinkle, on Flickr

IMAG2970

IMAG2970 by

jarrod vanwinkle, on Flickr

IMAG2969

IMAG2969 by

jarrod vanwinkle, on Flickr

IMAG2973

IMAG2973 by

jarrod vanwinkle, on Flickr

IMAG3009

IMAG3009 by

jarrod vanwinkle, on Flickr

IMAG3008

IMAG3008 by

jarrod vanwinkle, on Flickr

I aired out the truck to make it easier to work in the engine bay.

IMAG2989

IMAG2989 by

jarrod vanwinkle, on Flickr

IMAG2990

IMAG2990 by

jarrod vanwinkle, on Flickr

IMAG2991

IMAG2991 by

jarrod vanwinkle, on Flickr

IMAG2992

IMAG2992 by

jarrod vanwinkle, on Flickr

I installed quick disconnect battery terminals.

IMAG2965

IMAG2965 by

jarrod vanwinkle, on Flickr

IMAG2966

IMAG2966 by

jarrod vanwinkle, on Flickr

I also shortened the drive shaft. Hopeful it doesn't vibrate.

IMAG2980

IMAG2980 by

jarrod vanwinkle, on Flickr

IMAG2981

IMAG2981 by

jarrod vanwinkle, on Flickr

Last week I started the truck for the first time. I had never had the engine running since I got it. I wish I had test started it before I put it into the truck. When I first started it up I thought it was going to run away. Before I got the truck someone had gone through the pump before me. As when I went to install the new fuel pin and governor spring someone had already removed the tamper proof caps off of everything and some of the seals looked new. That and someone had messed up the idle adjustment screw. and at the time I could not turn it so I just left it where it was at. Well when I started it up I thought it was going to run away. unfortunately I had to pull the top of the pump off to adjust the idle screw. I had to put it in the vice and use a pair of pliers to remove it as when I tried to use a normal flat head like your supposed to I ended up snapping the tip off the flat head. Unfortunately the threads where mangled and I had to retap the top housing and I got a long full thread m6 bolt instead of the piece of all thread with a slot in the end. That said when I got it back together I had the idle bolt backed out all the way and It idles fine I don't know what its idling at but it sounds high maybe 1000 rpm But it may just sound high with no exhaust. Anyways I ended up replacing the seals on the top and installing a new throttle shaft bushing. As when I took the throttle nut off it was damp I don't know if it was the seal or the shaft itself as its a common problem and since I had the top off I figur I should replace it while I can. I also replaced the allen bolts as they were a bit loose and as I have to use a ball end allen socket I did not want to strip them out if I ever have to remove the top again. I ended up replacing them with a grade 12.9 allen bolt. So hopeful I will never have to worry about them striping out.

IMAG3004

IMAG3004 by

jarrod vanwinkle, on Flickr

I don't know if this is the stock adjustment for the smoke screw or not the paint looks untouched and it doesn't smost at all. if its stock adjustment i'm going to leave it alone.

IMAG3005

IMAG3005 by

jarrod vanwinkle, on Flickr

IMAG3007

IMAG3007 by

jarrod vanwinkle, on Flickr

The old throttle shaft bushing. I don't know if it had been replaced or not I though the stock one was brass as that is what it looks like in some pics. But this one was steel.

IMAG3028

IMAG3028 by

jarrod vanwinkle, on Flickr

Here it is running I tried to rev it a few times but I think it had air still in the lines because after I let it idle for a few minutes it reved fine, but it was getting dark so I did not record it. Maybe tomorrow. I have a leak in the return line and the power steering has a few leaks but it was getting too dark.

VIDEO0052

VIDEO0052 by

jarrod vanwinkle, on Flickr