Quote:

Originally Posted by Z10

Diceman, can you respond to this comment from "Airstream" from a TPI post I'm monitoring?

Quote:hey z10, I see you are building a surge tank. I was going to make a fuel injection cleaning tank that i was going to fill with cleaner fluid and pressurize it with air and feed it to injectors. My tank size and style was a lot like your surge tank. I discussed this with my brother ( a mechanical engineer) and he said "you must have domed ends, they look like bell ends. If not and the ends are sharp 90 degree transitions, these areas are stress risers, create flexing, and eventually crack". This would lead to pressurized fuel spray in a hot engine compartment with spark generators (coils, alternator, etc). My brother also said to look at any ASME (american society of mechanical engineers) tank and you will notice rounded ends. I work at a power plant with compressed air everywhere with surge tanks, etc, etc, and all holding tanks have rounded ends with an ASME id tag listing working pressure, burst pressure etc. I think the quality of your work looks great as i don't wont to rain on anyones parade, but when i switched careers from dealer mechanic to power plant work it was an eye opener. Keep up the good work, good luck Brian F.

|

Airstream, please go over to my build and copy and paste your comment.

http://67-72chevytrucks.com/vboard/s...=1#post6356218

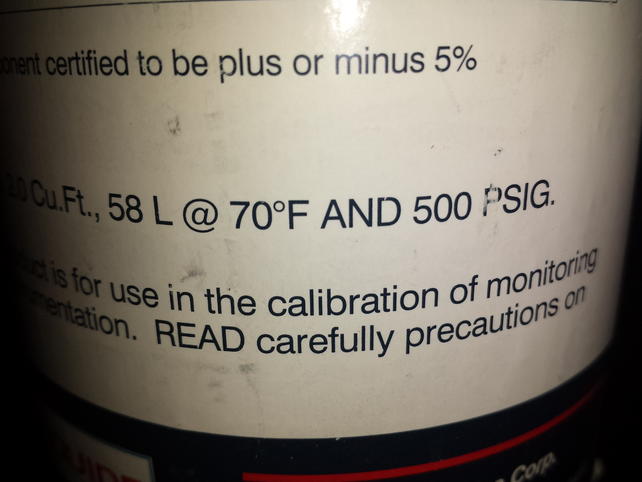

My surge tank was created by diceman50, I'm sure he'll respond. The tank was actually created by utilizing two DOT calibration gas cylinders which were originally rated at 500psi. As far as the domed ends, I'll default to your brother. On second thought I'll copy and paste your comment, just monitor it for his reply.[/QUOTE]

Diceman here,

The gas sample canisters we used are rated at 500 PSI and although they are flat bottom on the outside they have a very large radius on the inside which in effect makes them domed on the inside. However, the point is mute since in our application there is

ZERO pressure on the surge tank. We are using the mechanical pump on the engine to fill the surge tank with a return line to the main tank. The high pressure pump is inside the surge tank. It pumps fuel to the fuel rails after which excess fuel is returned to the pressure regulator which is mounted on the outside of the tank. Therefore no pressure is introduced to the tank. The pressure testing I did was for the fittings.