OK, so I drove the truck around for a year and a half or so (not sure exactly) before I decided something needed to be done. By this time I had gone back and forth several times on swapping an Allison 6 speed slushbox in it. The Ally would fix the gearing issue, but it would also alleviate the need to use a clutch. At this point my old ankle injury from my Army days had made walking with a cane necessary. My truck was sitting, partially disassembled, and I was driving a Ford (gasp!) with an automatic. As I mentioned in my above post. I was quite disgusted with the overall dissatisfaction of my swap, and the truck ended up sitting for quite a long time while I messed around with drivetrain parts or simply ignored it altogether.

Let me jet back a bit here: before the ankle became a real issue, I was shopping around for a Dana 60 front to replace my sad, overloaded 10b. One day, a fellow wheeler posts up that he has a first gen Dodge Cummins rolling chassis (no engine, trans, or body) with 3.07-geared Dana 61 front and Dana 70 rear. This would absolutely fix my gearing issue, and the price was right, so I jumped on 'em! It wasn't long after I dragged the pair of axles home that my anke issues started up, and got worse and worse. Somewhere in there I decided to go the Ally route, which means I no longer needed 3.07 gears. The Allison 6 speed has two overdrives: .71 (fifth gear) and .61 (sixth gear), so ideally gears in the 4.10-4.56 range would fit the bill, depending on tire size. This left me with two options: either sell the pair of axles and buy a D60 and 14b, or keep the oddball axles and re-gear the, if it's even possible.

I ended up choosing option #3. To begin with, nobody had ever bothered to attempt to re-gear the unique 3.07 D70U since regular D70's and 14BFF's are a dime a dozen, and I wasn't going to for that same reason. Besides, D70u's have wussy 32 spline axle shafts :roll: Also, re-gearing a 3.07 D70U or D61 is more than a simple gear swap: the pinion head on a 3.07 gear set is massive compared to lower (numerically higher) gears. Here's a 3.07 D61 pinion next to a 4.10 D60 pinion:

The pinion is too large to fit in a regular D60 or D70 case, so Dana cast special housings with the pinion moved further away from the ring gear. These became the D61 and the special 3.07 D70U. So, what to do? Well, I would never find a Chevy or Dodge kingpin 60 for as cheap as I scored the kingpin 61 AND D70 rear, so it made sense to keep the D61 iand re-gear it, f possible. Also, Dodge kingpin 60''s and the otherwise identical Dodge D61 front actually have a track width that more closely matches the rear axle, and the perches only differ by 1/4" per side so they are very easy to fit into a square body Chevy in place of a Chevy front axle. Like the Chevy axles, they are right hand drop, have internal hub locks, nearly identical brakes, and non-neckdown 35 spline inner/30 spline outer shafts (slightly different lengths from the Chevy, due to the axle being a bit narrower). In other words, from the pumkin-out they are identical to the same year Dodge D60, including the desirable kingpin knuckles. So, there is nothing to be gained by replacing it with a Chevy (or Dodge) 60... if I can re-gear it.

A lot of people online said the D61 is junk because it can't be re-geared. I did some research, including talking to Carl Jantz (of SuperJeep fame) who does lots of cool axle upgrades (like fitting 10.5" D70 gears in a Dana 60!) and measurements of my own housing, and found that the pinion is offset 7/16" from a standard D60. Which means all I need (in theory) is a 7/16" ring gear spacer, some suitable bolts, and I'm set! With that plan in place, I sold the rear D70 to a guy on 4BT swaps, and got started rebuilding the D61.

One of my reasons for dissatisfaction with the swap was that a lot of stuff got hurriedly slapped together. It was reliable, but looked like crap. With that in mind, I completely stripped the axle apart and cleaned it. Cleaning it was not particularly enjoyable; it required liberal use of a needle scaler to get all the crud off it:

The crud came off in chunks:

The upper kingpins themselves were hashed, so they needed replacement. If you ever have to remove them, forget about suggestions of using a long bar (likely to split the pin, at which point you're in for a real ball of laughs getting it out) or the smoke wrench (didn't work for me). Get your cutoff wheel and slit it a short distance above the C. After that, you can break it free with a regular breaker bar:

The equally fun part is torqueing the new ones. The spec is 600ft-lbs. Yes, SIX HUNDRED. I used a 3/4" drive Snap-On ratchet with a 7/8" socket, a 7/8" hex long lug nut, a 5 foot long bar with a nut welded on one end, and a 1/2" drive torque wrench with a socket that fits the welded-on-the-bar-nut. The total length of bar+torque wrench was 6 feet from kingpin to torque wrench handle, so by setting the torque wrench to 100ft-lbs, the bar multiplied it to 600ft-lbs at the kingpin. It ended up being a three-man job, but you don't want to skimp here: if the kingpin comes loose it will wallow out the threads in the C, ruining it.

I also cut off the cheesy Dodge shock mounts and welded on some proper ones.

I figured while I was at it I might as well weld the tubes to the pig to prevent them from ever spinning. I used my trusty Eutectic 680 rod and needle scaler to weld and peen, weld and peen, weld and peen. I also added a bracket for a future panhard rod. Then, finally, paint!

I cheated on the rest of the parts and had them sandblasted. After the axle, I was DONE with cleaning crusty crap! I did get remanned calipers though.

Remember when I said the Dodge and Chevy D60's have

nearly identical brakes? Well, the non-Cummins Dodge 60's (or perhaps the pre-89, not sure, actually) have 1-¼" wide rotors, while the Chevy 60's and Dodge Cummins 60's and 61's have 1-½" wide rotors (same part number, in fact). Which means mine has 1-½" rotors. The calipers are identical

except for the banjo bolt that retains the brake hose: The Chevy calipers are 10mm, while the Dodge is 7/16". Since I already had a pile of Chevy banjo bolts I went ahead and got Chevy remanned calipers:

Yeah, they're big and they weigh a ton. So much for better fuel economy

Also, remember when I mentioned that re-gearing would require a spacer? Yeah, I got a certain machinist [cough]Todd[/cough] to make me one. That+proper length ARP bolts+good used 4.10 R&P set = a regeared D61.

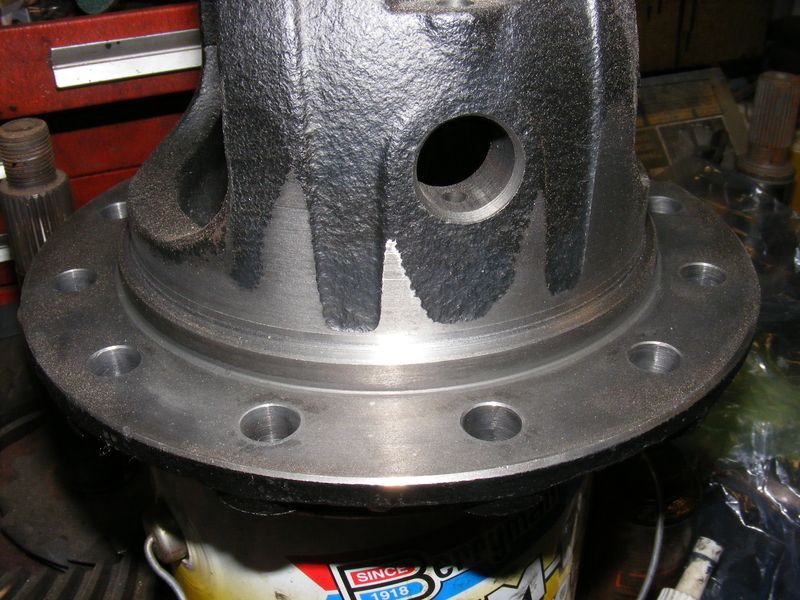

A small amount of machining was required on the carrier so the spacer would clear:

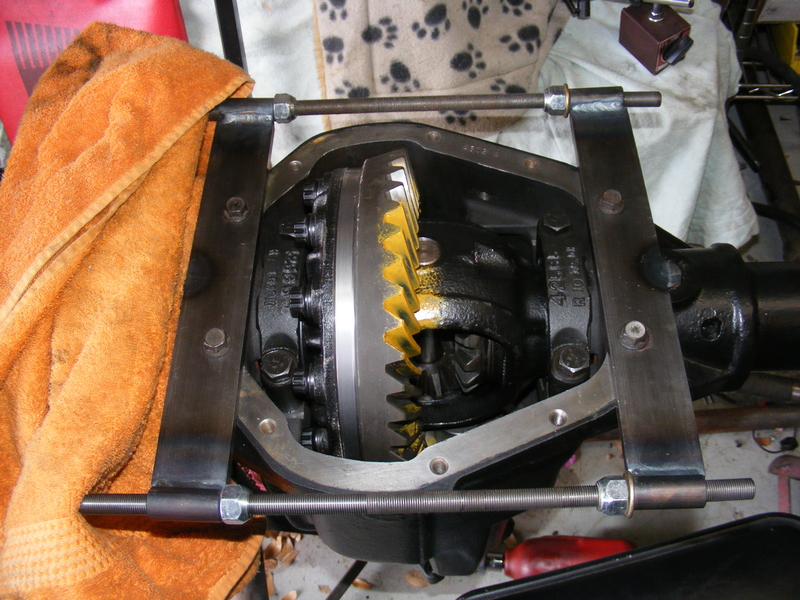

I musta done something right, because the 4.10 D60 gears set up perfectly:

All buttoned up, put together, and ready to go:

But wait! I still need a rear axle with 8 lugs and 4.10 gears. Hmm.... guess we will have to wait and see what I end up with