Dust/spray booth

These soda blasters are messy!

I did not think my neighbors would appreciate a large white cloud taking over the neighborhood every weekend, so we did a little research and came up with a pretty good solution. Inside the barn we have an area 21' deep X 26' wide x 9' high. We wanted to be able to grind, sand and blast and keep the dust to a minimum, paint at least smaller parts and then prime. We are not looking to spray the final paint in here, but who knows?

I found these

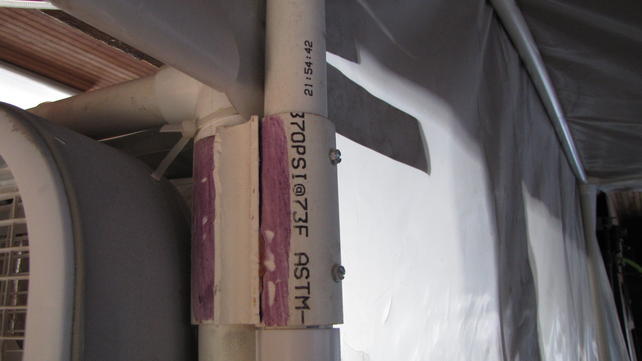

plans and modified them for our specs; 20DX10WX8H. Instead of rounding the top, I made the top flat by using the three way connectors. The entire parts list can be picked up at the big box store except the three way connectors, slip T and c clamps. I found them by searching for the manufacturer, Circo Innovations. There are several suppliers out there. These three parts do make the project though. I modified the plans (see below), created the pick list and ordered the stuff. Tim and I got the frame together pretty quickly. The c clamps keep the plastic (4 mil for us) right where you need it. I used metal clamps from Staples down the sides for a quick release to fold up the side to allow access. We used self threading screws to keep the parts where you want them, but still allow for quick dismantling.

The hinges are glued together with pipe glue. I glued three together to create more bonding surface. You can see in the top hinge I then cut off most of the third pipe to allow room for the door to close.

The fans are cheap box fans. I put two on the door that flow air in to the room, and one on the other end (near the exterior doors) that flows out of the room. With this setup, I can create negative pressure for blasting and positive pressure for spraying.

The door was little tricky as this soda material will find any gap and spread to any surface it can find. I build a flap around the perimeter and then used a few small bungee cords to draw the door closed behind me.

So far the results are really good. The soda blasting and grinding have been really well contained. I am not at the point of spraying, but am closing in on it.