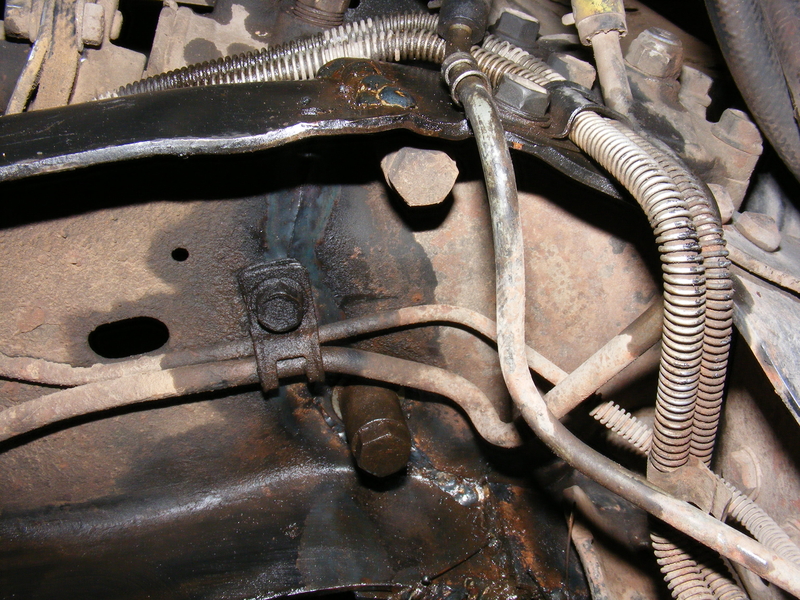

The next step in the swap was to remove the 6.2, trans, and transfer case and get the engine bay ready to accept the Cummins. Removal of the existing drivetrain was easy, but then I was at a crossroads. The existing frame had been cracked and repaired multiple times in the steering box area:

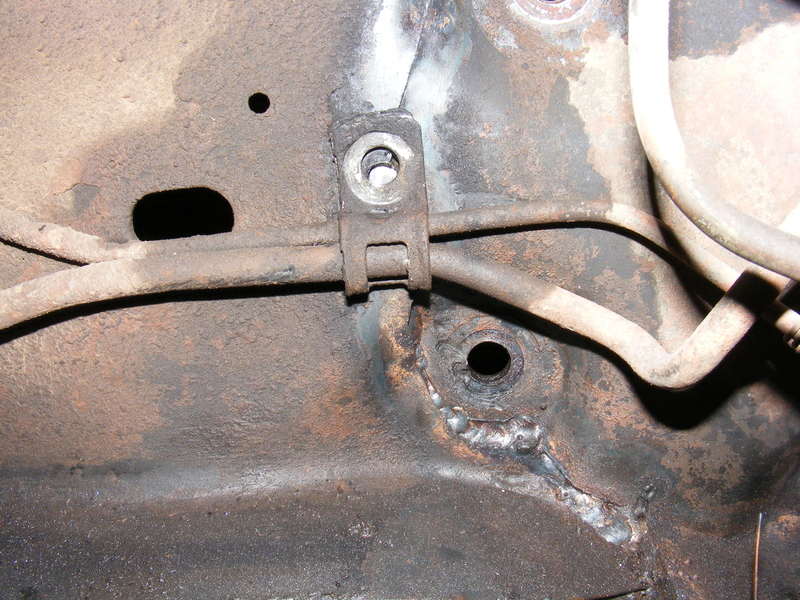

These cracks are pretty typical, particularly on the 1/2 ton frames. All of the force from the steering box is concentrated on the area under the four bolt spacers, and 1/2 ton frames are particularly thin. I had two options: repair the frame, or replace it. I chose option 3: replace the front frame section with this:

That is a front frame section from a 1 ton square body truck. By replacing my existing front section with this, I get a crack-free frame that is nearly twice as thick as the 1/2 ton frame

Now all that is needed is to

the existing front section:

Then

the ends, put them together, get it aligned, and

it up:

As with the original frame I sat the front axle 2" forward, and within 48 hours of making the first cut it was sitting back on the tires:

There were still a few mods to be made though. The existing crossmembers are in the wrong places, and they are flimsy and weak, so they needed to go. Before their removal I welded in a new front (i.e. under-core-support) crossmember made from a piece of 2x4x3/16" rectangular tube:

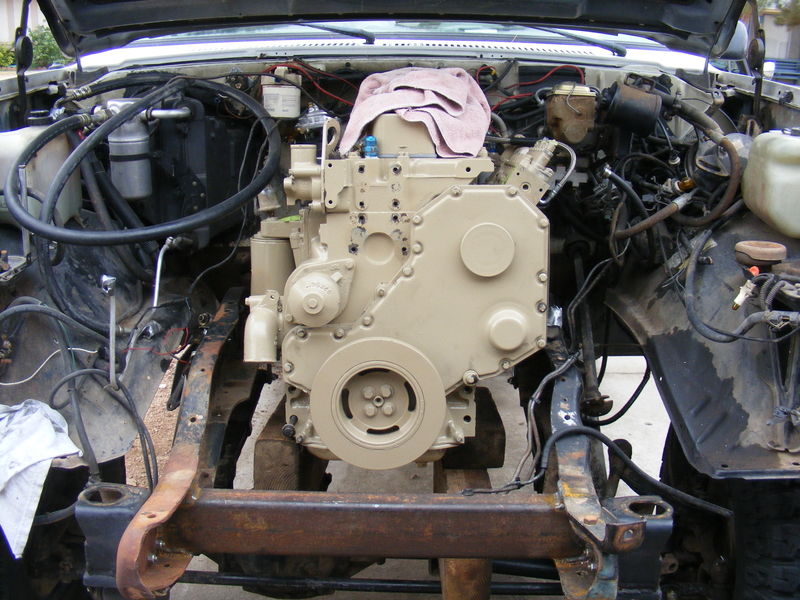

After that I was free to air-chisel the heads off the rivets retaining both stock crossmembers and remove them, and finally do the first test fit of the Cummins in the engine bay:

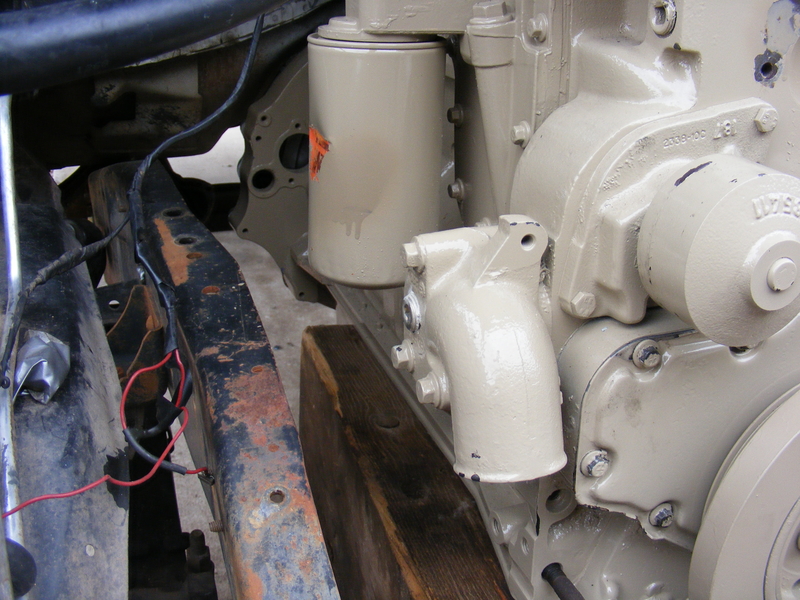

Fortunately for me, my roommate had some big pieces of rectangular wood that were perfect for supporting the engine atop the front axle

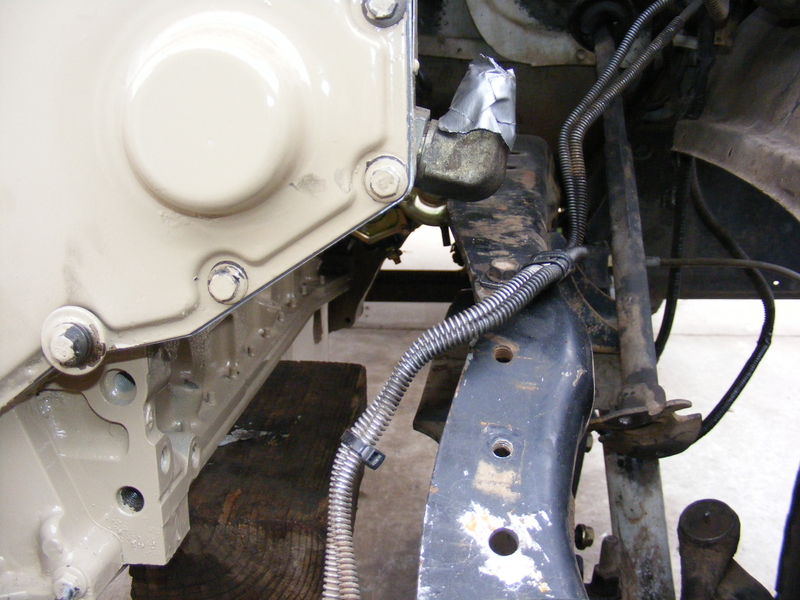

There was plenty of clearance between the engine and the frame and axle:

At this time the main limitation to how low I could set the engine was interference between the power steering pump inlet fitting and the frame:

I could of rotated the pump and changed the fitting to set the engine lower, and in fact I considered it. You will see later in the saga why it's a good thing I didn't!

At this point the major issue was that the bellhousing bolts were touching the tunnel:

My truck still had the stock 19-year-old body mounts, which had probably crushed around 1/2 inch. New ones would give clearance, but I figured a bit extra would be nice. With that in mind I ordered a new set of urethane body bushings and a

one inch body lift kit from Off Road Design. This gave a comfortable amount of clearance everywhere and allowed me to flatten the front-rear engine angle a bit more.

I also

a large hole for the transmission shift tower. I would fab a cover for it, and the extra room made trans R&R much easier.

Otherwise, the amount of setback was good:

Next episode: Motor mounts n' things.