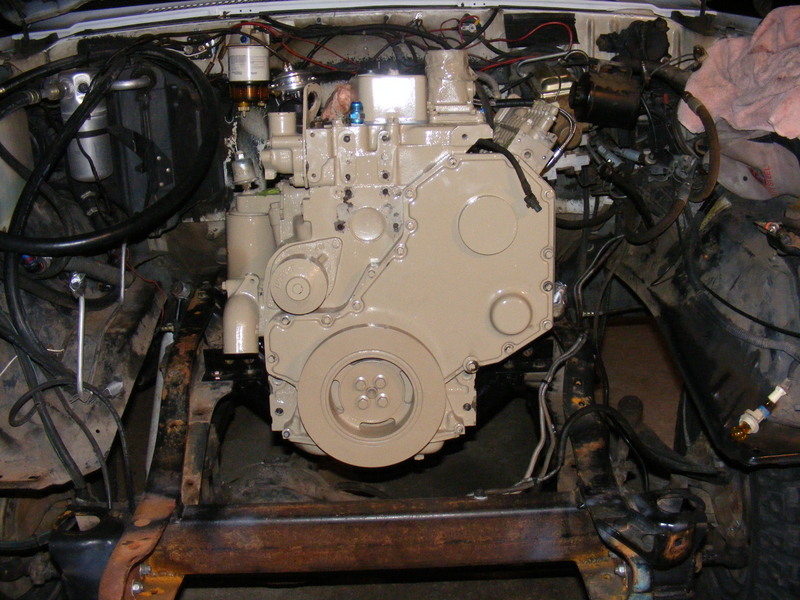

Since much of what I am about to show was done hurriedly and got changed later on I will quickly go through it. First, the engine is no longer sitting on wood:

And has a crossmember:

For those who say "I can't see the motor mounts very well", that's probably a good thing. I was welding it with my roommate's Miller 180, and it is in desperate need of a new wire conduit/hose assembly. The wire keeps hanging up and feeding in stuttering, jerking fits, making it just about impossible to get anything resembling a clean, decent looking weld

Anyway, they are nothing special. Pretty much similar to ORD's motor mounts for the SBC/BBC, but made to fit the Cummins. They are also much beefier than the ORD mounts to deal with the weight and torque of the Cummins. The bushings used are 1-5/8" OD with a 3/4" sleeve in the middle and a 9/16" bolt holding everything together.

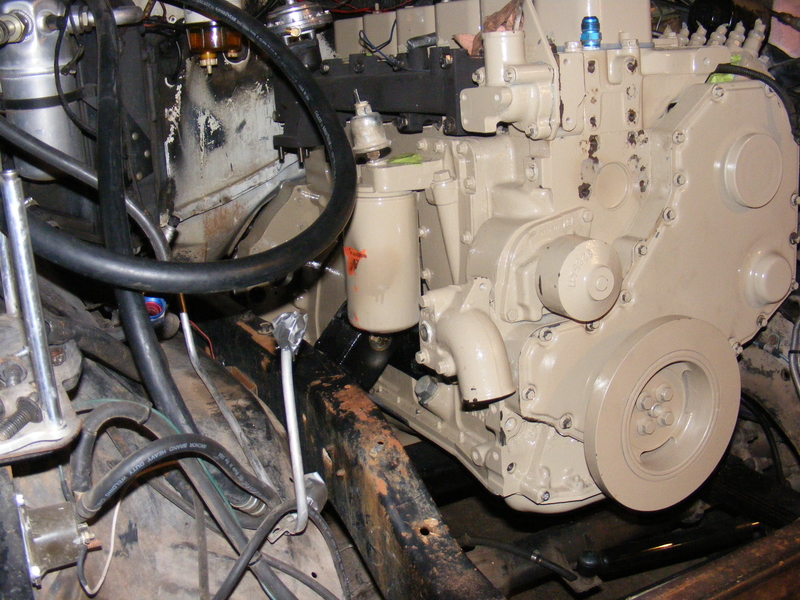

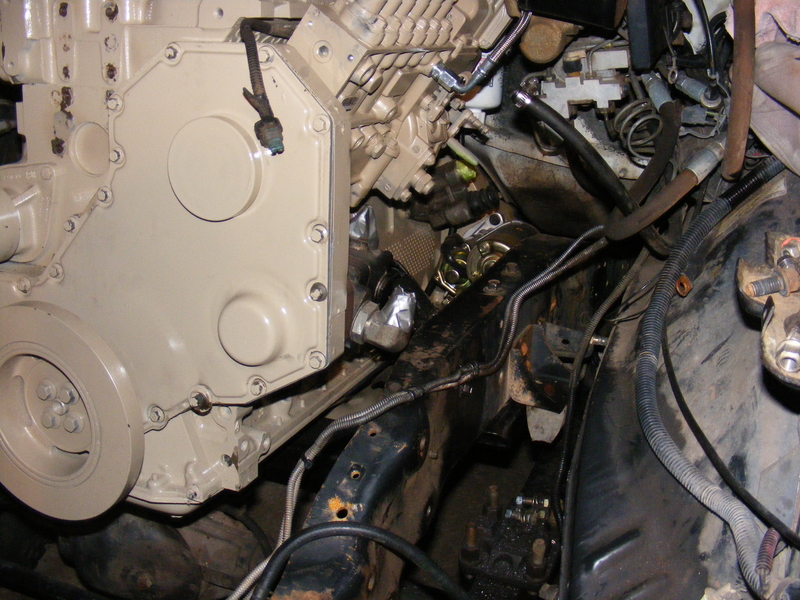

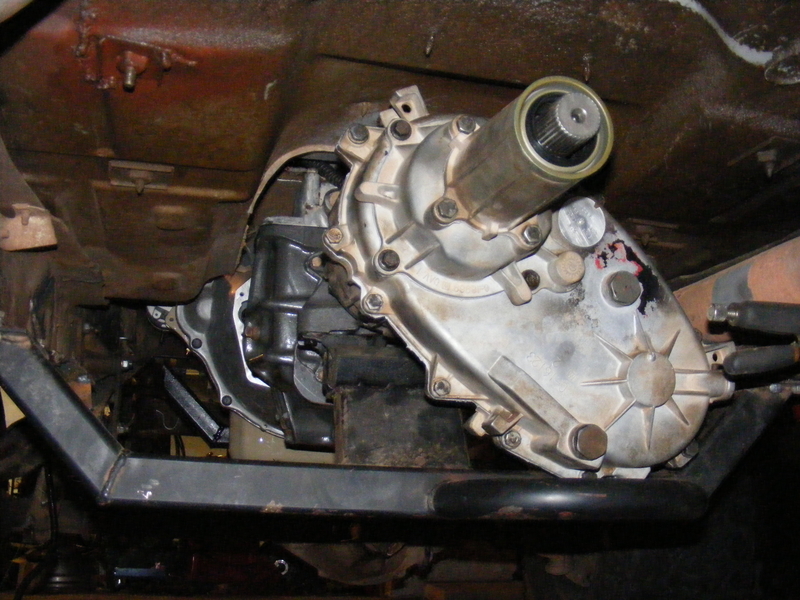

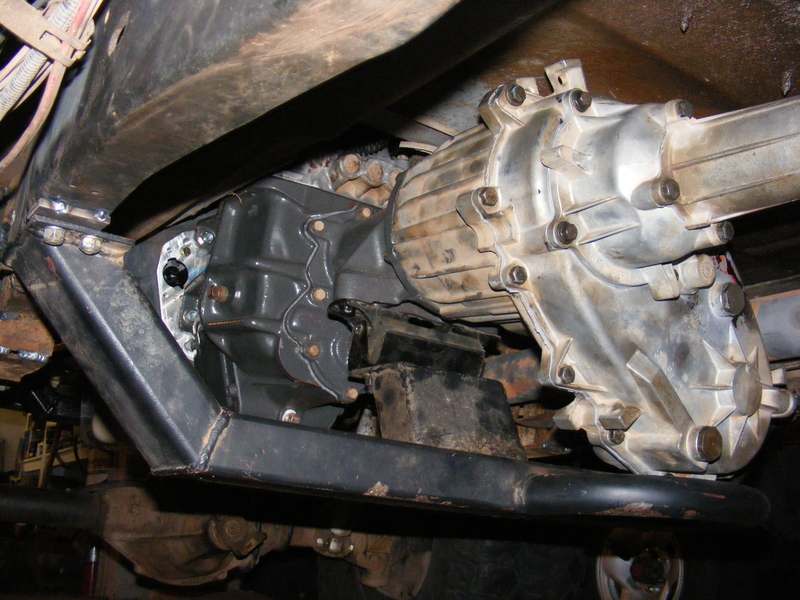

Some underside pics:

The trans crossmember is the same one I used with the 6.2. Somewhere in here I got good used 3.42 gears and re-geared the axles. 3.42s were necessary to get the road RPM reasonable with a non-OD transmission.

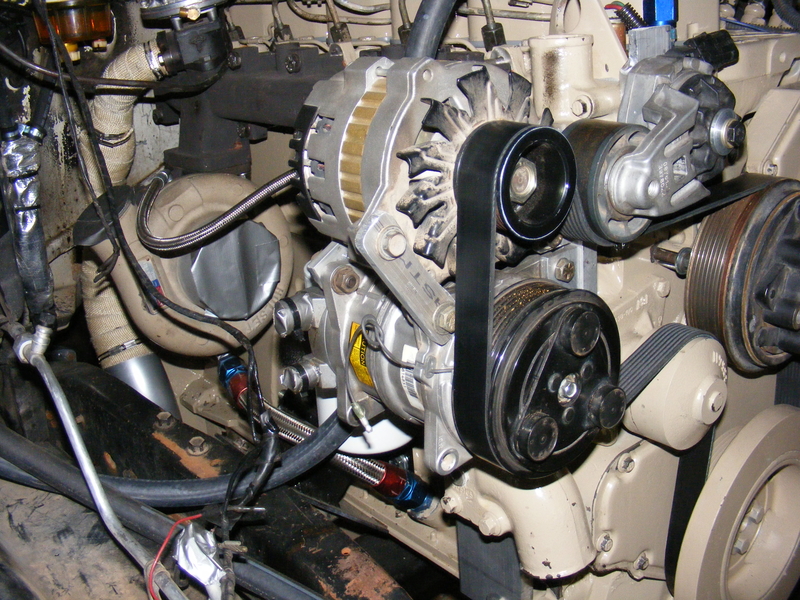

I initially had done a turbo oil drain, decided I didn't like it, and made a new one:

Drain is connected using -12AN steel-braided hose:

Exhaust downpipe:

Installed:

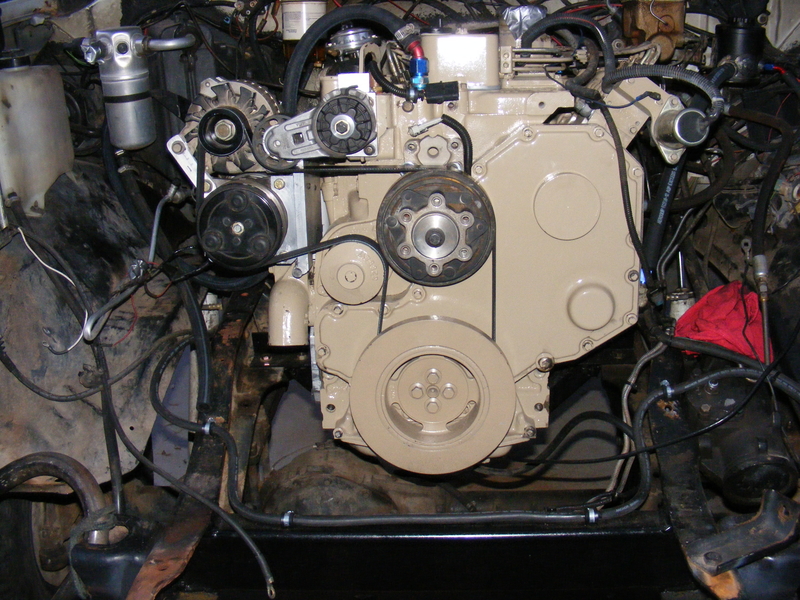

And accessory brackets:

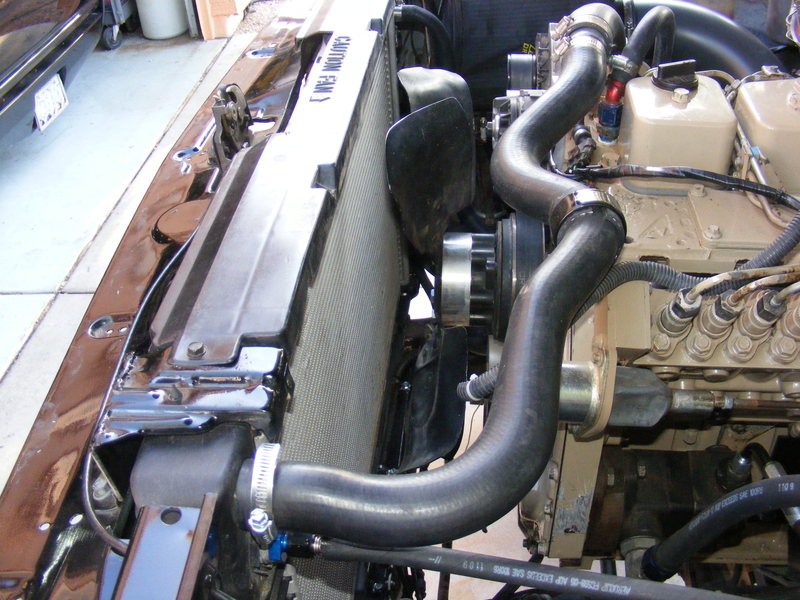

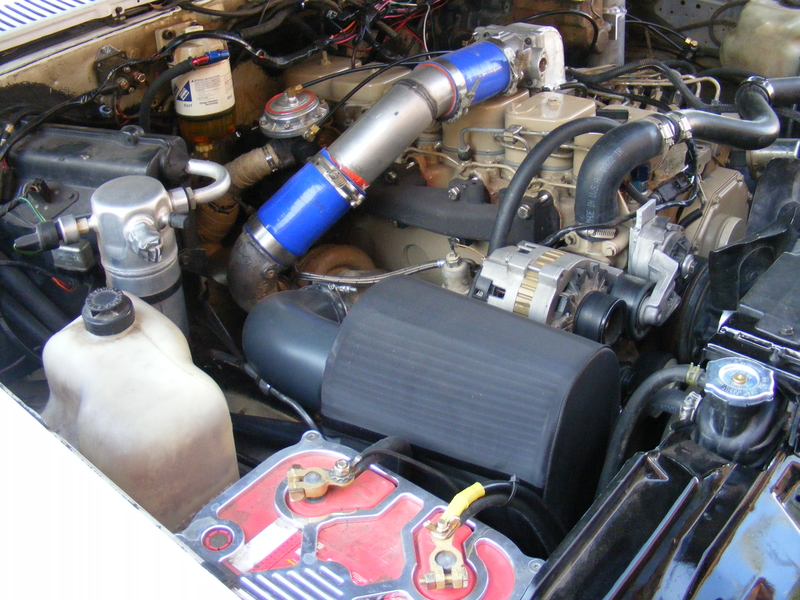

Here it is mostly put together:

I drove this setup for over a year and found what was good, bad, and ugly. It had adequate, but not spectacular, power. It was still stock, which is rated at 160HP and 400LB-ft of torque. It ran cool, even in the middle of the AZ summer. The engine fan, which was driven by an electromagnetic clutch, was only needed when the AC was on. Speaking of AC, it didn't work very well for a number of reasons. First off, the "134A" condenser was a serpentine type, which sucks. Second, I used the 6.2 fan, and it just didn't seem to pull enough air through the cooling stack.

The gearing left a bit to be desired. With the stock governor the engine would run out of RPM, require a shift, and the next gear would pit you on the low side of the torque peak. This was only a problem in the mountains. Combined with EGT issues after I slid the stock fuel plate forward (a common issue when doing that mod) I would sometimes end up stuck in third gear doing 45MPH on 6 and 7% grades. If I hit the hill doing 70+ I could stay in 4th, but often traffic conspired to slow me down, and once RPMS dropped below 1600 in 4th EGT's would skyrocket if I tried to accelerate. I would have to shift into thrid and stay there until the hill was crested. That sucked really, really, REALLY bad. The fix is either different gearing, 3k or 4k governor springs, a proper fuel plate and pump tuning, intercooler, or a combination of those. We will see which one(s) I choose

The stock push-pull steering left a lot to be desired, but replacing it with crossover steering was already planned. What wasn't planned was replacing ball joints :roll: It seems the extra weight combined with 37" tires is a recipe for frequent ball joint replacement. Since frequently replacing ball joints brings the suck, a permanent fix was needed.

Leaks, leaks, LEAKS!!!! Every friggin thing on this swap leaked!. The t-case leaked, the trans leaked (due to the wrong sealer being used - never use Ultra Grey, it sucks), the power steering leaked (worn sector shaft bearing causing a leaky seal, thanks to big tires and push-pull steering), but worst of all the engine leaked. BAD!!!! It started out clean, and a year later it looked like it did when I brought it home

The final straw was when the head gasket started leaking oil out one side and coolant out the other. Nothing beats the joy of replacing a head gasket on a Cummins

Finally, there was fuel economy. In the city it was quite good: 18mpg tanks were easy when I stayed below 60mph, even with in-town stop-and-go driving. On the highway the engine was operating WAY above it's most efficient RPM due to gearing. When I planned the setup I wanted to run 3.23 years, but they proved impossible to find, so I settled for 3.42's. At 65mph I could do 17ish, but at 80MPH I would drop down to 14mpg. Better gearing would improve mpgs at all speeds, but especially highway MPG. Diesel efficiency drops rapidly at higher RPMs, so keeping it as close as possible to the torque peak during highway cruise is necessary to get the kind of mileage the engine is capable of. Something would have to be done!