During the last nail-biting cliffhanger, I had to get an 8 lug rear axle to complement my brand used D61 front. I could have re-geared my existing 14bsf, replaced the 6-lug shafts with 8 lug units, threw on 8 lug drums, and headed down the road (metaphorically, at that point). However, I have a mental block when it comes to having a rear axle with a smaller R&P than the front.

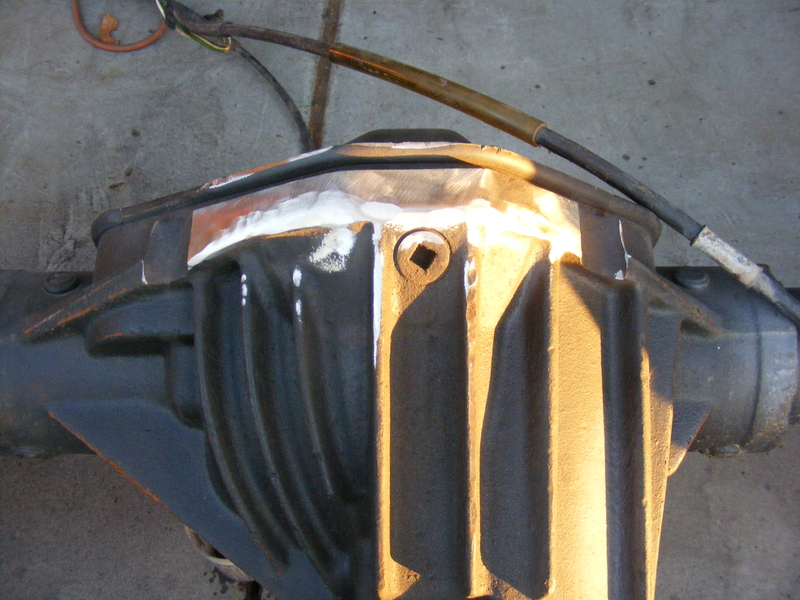

With that, my ultimate choice was boringly predictable: I got a 14bff. In this case, it's a 2003 AAM 10.5" 14bff with disk brakes, 4.10 gears, and a gov-bomb diff. The first thing I did was shave the bottom to hopefully reduce the number of the dreaded code 14's:

After that came the usual

to relocate perches and add new shock mounts. Before I slung the axle up under the truck I had a couple other things to do. First was rebuilding the rear spring packs:

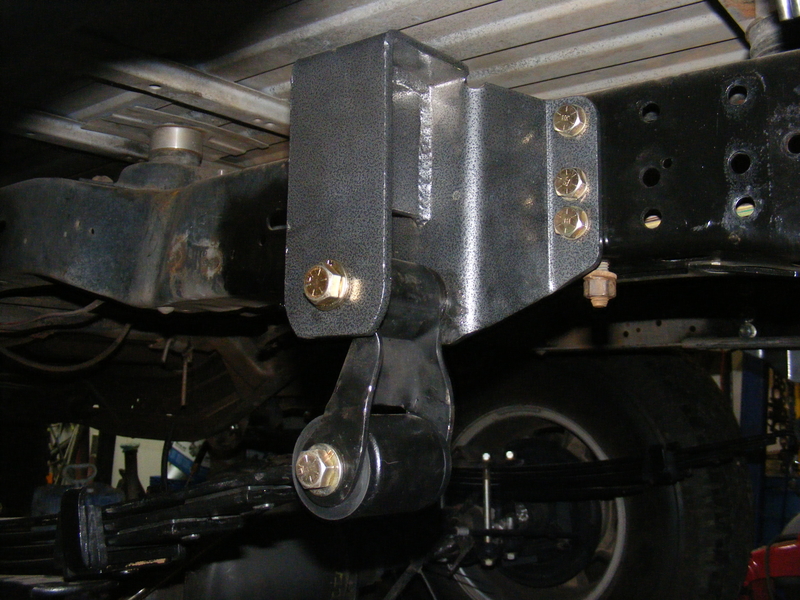

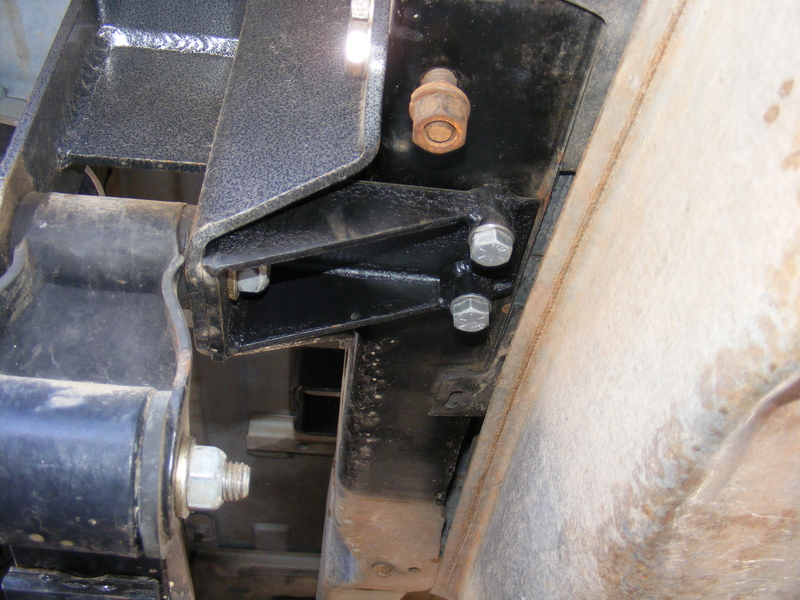

Then replacing the echobit flips with regular bolt-on flip brackets. This required liberal use of the air chisel, which makes the neighbors oh-so-happy

The result was this:

So now I had axles, springs, and mounts ready to go, but I still needed 8 lug wheels with a minimum of 16.5" diameter to clear the rear calipers, along with tires on said wheels. For that, Craigslist came to the rescue. I found a guy selling a set of just what I needed:

Yup, good ol' H2 wheels with good BFG Mall Terrains. Guy was asking 6 bills, but I chewed him down to 4. Or, more precisely, his wife made him take the offer of 4 in order to get the tires out of the garage

You shoulda seen what he replaced the perfectly good factory wheels and tires with on his poor H2

With that last piece of the puzzle fit I can finally get the truck resting on tons:

So far, so good. Now, if you read the whole drama thus far you recall that I had replaced the entire front section of frame with a 1-ton section due to massive cracks in the steering box mount area of the original frame. After a year and a half or so the new 1 ton frame was showing no signs of fatigue around the box mounts, but I wanted to make sure it would NEVER be an issue. The usual method of prevention on a stock frame is a bolt-on brace from outfits like ORD, but my removal of the original crossmembers (and reluctance to buy stuff I can fab myself) made that no longer an option. The second method is boxing in that section of frame. That is the route I chose, and it was made easier and better by the non-stock crossmember that I added which would tie everything together.

First step is to trace out the pattern and cut it out of 1/4" steel plate. Then clamp the piece inside the frame and use a drill bit to transfer the box mount hole locations to the plate. Drill out to 3/4", put in the frame, add spacer sleeves, tack, remove, weld sleeves, and you have this:

After thoroughly cleaning the frame area where the plate will weld in and spraying both it and the plate with weld-through primer, it got welded in, painted with chassis paint, and the box bolted up:

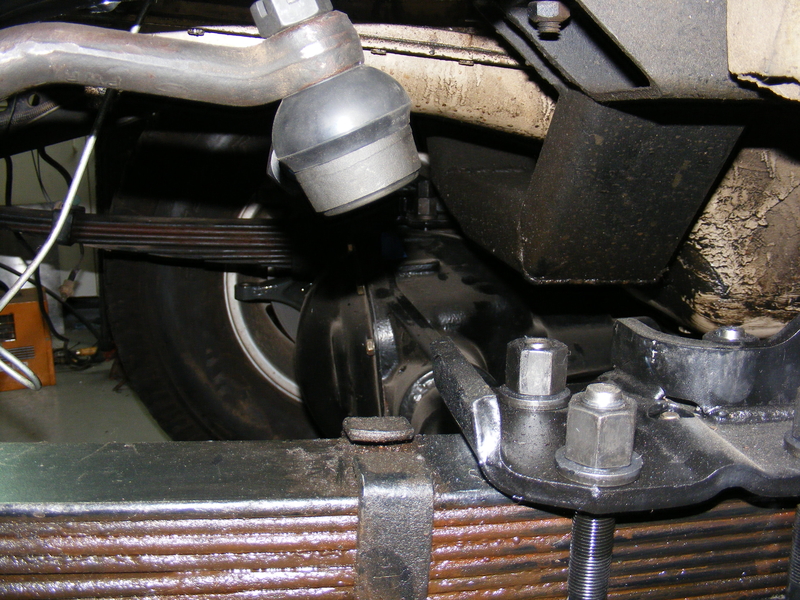

My truck, like all solid axle 4WD GM trucks, originally had push-pull steering. Mine worked fine until I moved my axle forward 2 inches, which shortened the already short stock drag link by the same amount. Now it had serious issues turning when flexed, and had developed bump steer

This sucks, so I was going to convert to crossover steering, which requires a box with a 2WD sector shaft. By this point I already had new tie rod and drag link ends from Parts Mike, as well as a 2WD box and suitable Pitman arm from a friend. I also had a stick of 1-½" .120 wall 4130 tubing and these parts that Todd made:

With the box bolted up, I installed the Pitman arm and temporarily installed a DLE to check stuff out. Hmm, looks kinda close

A quick cycling of the box confirmed that the DLE mount bolt clears the frame (BARELY!). As for the clearance between the spring and DLE, that will require bumpstops. Eventually. In the meantime, there's no danger of contact with my truck holding down concrete