The next thing I addressed was the turbo oil drain. When I pulled the boost tube off during the reseal there was a fair bit of oil on the inside. The oil could be due to one or more reasons: Maybe the turbo seals aren't sealing? Maybe there is too much oil feed? Maybe my drain didn't have a steep enough slope?

I decided to address the latter two potential issues. If the turbo seals aren't working I will need either a new turbo (HE351VE would be sweet!) or more new parts for my WH1C. Now, the problem with fixing the drain is that I would have to redo the right side motor mount in order for the drain line to have a straight shot. Since I wan't really happy with the mounts anyway I figured I may as well replace them both.

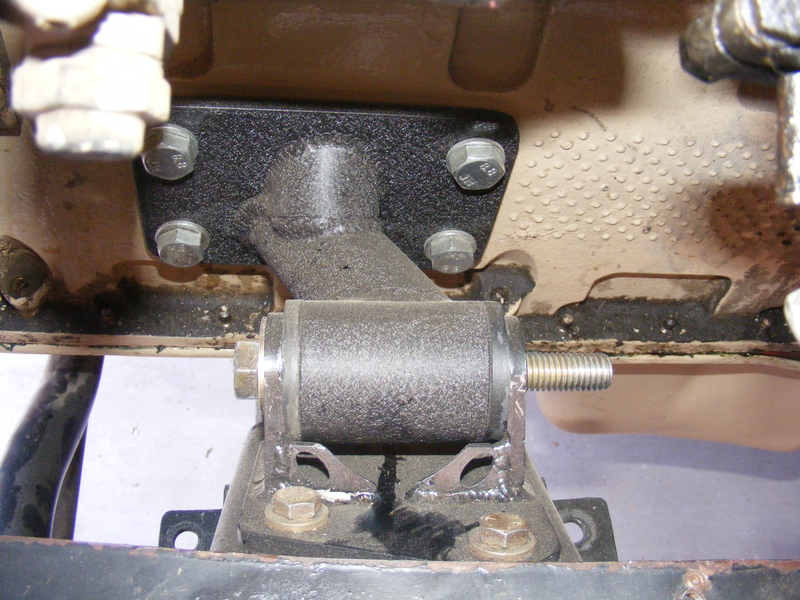

The previous mounts, using urethane spring bushings, absorbed engine vibes quite well so I saw no reason not to use the spring bushings in the new mounts. I liked the tube mounts Todd built for the LQ4 engine in his Jeep, so I figured I would make tube mounts as well. This is what I ended up with:

The tube between the engine-side plate and the bushing is 1-¾" .120" wall 4130, with a wedge of the same welded in as a gusset. Assuming the welds don't crack it should be plenty strong.

Here is the right side mount along with the new turbo drain plumbing:

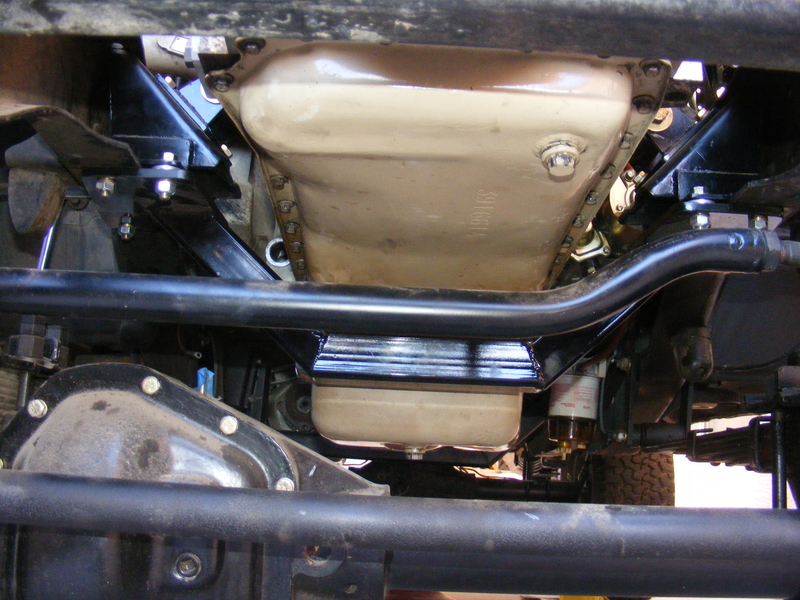

Along with the mounts proper I also modified the frame-side mount perches and made a new crossmember that better ties both sides together:

In the last pic you can also see my drag link. The bends were needed for oil pan clearance when the right side is at full stuff. It still hasn't been fully tested..... The crossmember works great though. I can jack one side up and there is no frame twist or flex.

The other item I addressed was the turbo feed line. I made a new one using reuseable fittings and steel braided Teflon hose since the old one had rubbed on something and got frayed in one spot. What you can't see is the fitting going into the turbo that restricts the feed to the same size orifice as the stock banjo fitting.

In stock form the fuel and brake lines run down the passenger (right) side of the truck. Unfortunately, the Cummins also runs it's exhaust down the right side. I figured this was as good a time as any to put new fuel lines down the drivers side frame rail. I decided to use the same reinforced nylon diesel fuel line used in MD and HD trucks, tractors,, etc. It's inexpensive and tough. I didn't care for the use of brass compression fittings though, so I used barbed AN fittings. What I did was heat the end of the hose with a heat gun to soften it a bit, them press it onto the barb. I also put an HNBR o-ring between the first and second barb before pressing the hose on to ensure there would be no air leaks. Air leaks would be A Bad Thing™.

That is the return line which doesn't need 3/8" ID tubing, but I liked the idea of having just one size of fuel line. Here's the return line dropping down, and you can see the supply line going into the lift pimp:

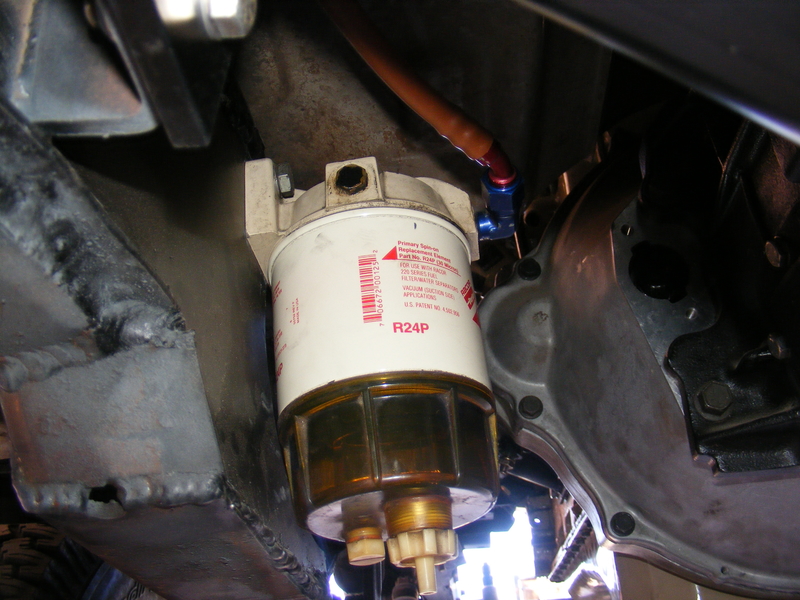

The supply line comes straight from the Racor filter, which I relocated to the frame rail:

Here's a better look at the Racor. It will certainly need a heavy skid plate to protect the plastic bowl, but being positioned on the frame rail means it is siphon fed from the tank so I can open the water drain or even change the filter without letting air into the system:

I used plenty of Adel clamps to secure the lines:

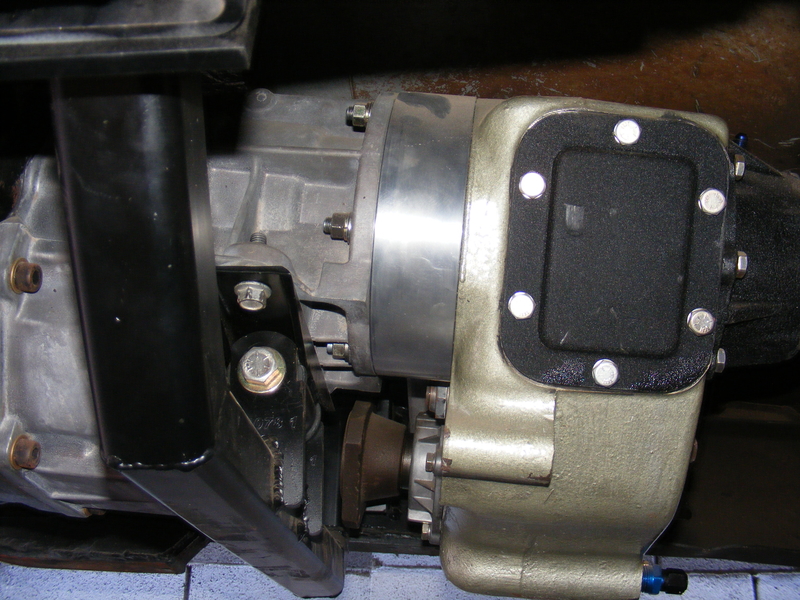

I also got the trans and t-case installed. Maybe I didn't look hard enough, but I didn't find anyone who made the wide truck trans mounts in urethane, and the parts store rubber ones are crap, so I used another spring bushing:

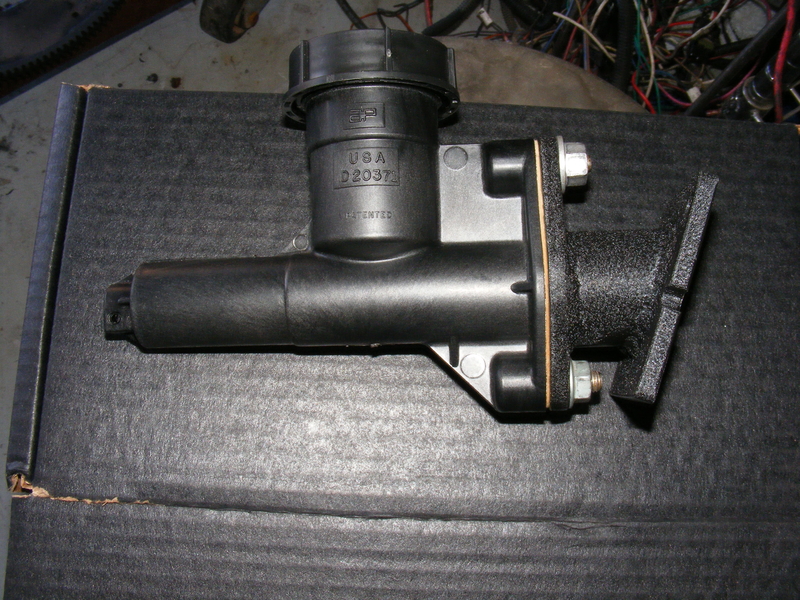

I also needed a new clutch master cylinder mount since the old one went with the old master when I sold off the 465 setup:

One real annoying item was my clutch pedal squeak. I ended up pulling both the clutch and brake pedals and replacing the bushings. I also eliminated the stock-type clutch rod and replaced it with one made from tube and using a Heim joint to attach the rod to the pedal. Major improvement!

That's it for now, but stay tuned; I ain't done yet!