The intercooler piping saga begins...

I didn't have the parts that I needed to complete the bottom radiator piping, so I decided to start the intercooler piping.

One major problem, the blower inlet points up. Here it is in the center of this photo (with the Gorilla tape around the inlet). I need it to point forward to meet the piping from the intercooler.

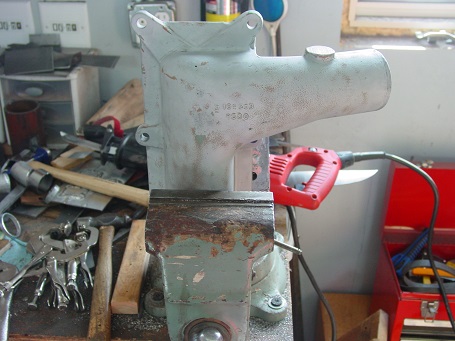

Here it is in the vise awaiting major surgery:

There's no turning back now!

Welding cast aluminum - no problem - right? Well it was for me. This casting was full of inclusions. It was the devil to weld.

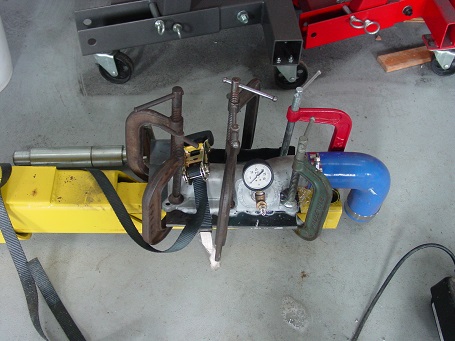

I made a test apparatus to test the welds. Here it is in the apparatus for the first time. I obviously didn't have the clamps tight enough since there are bubbles around the gasket.

By the time I got the two pinholes welded up, I had lots of practice in putting the housing in the test fixture. The pinholes were caused by two nasty inclusions. I would weld, test, grind, weld, test, grind, etc., etc., etc. I am not proud of the looks of the weld only that it doesn't leak.

Between the fitting, welding, testing and re-flattening the sealing surface, I must have 30 hours in this part. Good thing I'm retired - I would starve to death trying to make a living this way!