Got the control arm back from MD Shot blasting today, blasted and primed, it's in really good shape.

I've managed to strip out the old bushes and shafts (you can't beat a 3ft power bar) and put a coat of high build etch primer on today, but before doing that I prepped the arm (I'd done the other three a while back).

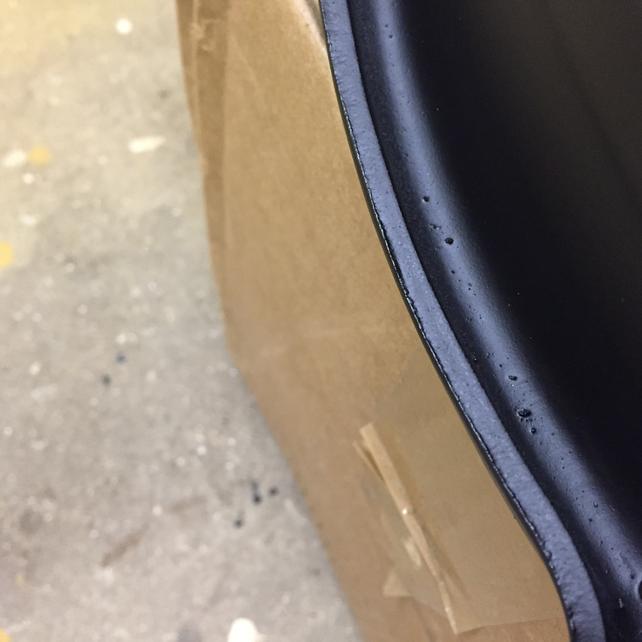

I'm probably stating the obvious but it really is worth spending 20 minutes "de-burring" the edges if you want to avoid rust. The majority of edge burrs are caused during manufacture, some are from the blanking dies, however, some are also caused by the material flow which is a by-product of this type of stamping process.

I've worked for a number of car manufacturers over the years and done a fair bit on suspension. In-order to give anti-corrosion warrantees the OE's perform a CCT test (compound corrosion test) where parts are literally sprayed with a near boiling (like 180 - 200 degrees) caustic solution. Parts are checked for corrosion every 100 hours or so and the point at which they start to rust becomes the rating. (like 200 hours CCT, 300 hours CCT etc.) every failure I ever saw was caused by edge burrs.

Ofcourse I should have done the prep before blasting!!

Two coats of primer on the edges also keeps the rust away!