Quote:

Originally Posted by 68Gold/white

Man-o-man, a lot of great work going on there. Making stuff work on an ordinary 1/2 ton pickup is a walk in the park, compared to ALL that you are doing!!!

Job well done...

Some thoughts from me, thoughts, if nothing else...

I'm sure you know Vintage Air AC units, have the AC and heater stuff ALL under the dash, and in the cab, nothing under hood. Of course, it's only money. You not working for the moment, that's a future thought.

I like the group 31 batteries with the threaded studs on them. Less worries about battery connections, and more power out of them, and not much more than a car battery....just a thought for when you get your end result battery box(s) finished...

Carry On, Man!!

|

Thanks! I enjoy custom fabrication this build is super tame compared to what I usually build. But this build was supposed to be a quick and easy build, But between my back injury and not working it's been way drawn out. There will be more fab work in V2 and V3 of the build. With that said Vintage Air is on my list but it won't be until V2 or V3 of the build along with compound turbos and a 4 link in the rear. but for now I just want it make it a driving project So I can get back to my other builds. I have never thought about using group 31 batteries. I ran a optima in my last rock crawler that I Built/ It had internal threads and normal post, I ended up using both. But I think a threaded stud would be very beneficial and simpler. I'll have to look into it when I have to replace this battery. I think this one should be enough for what I am running, it's a 900 cold cranking amp battery. I think first gen cummins only ran one battery, But down the road I want to install a 20 gallon air tank to run my bags and I want to have on board air to run air tools. I'm thinking of running 3 electric air compressors and may need two batteries, But I also have a old York air compressor that I may try and fit, then I would only need one electric compressor and not need a second battery, but only time will tell.

Now back to the build.

So I bought a 2005 chevy 3500 master cylinder, another member is running one on his build with the jb8 brakes. Unfortunately assumed all hydro boosters were the same, I was wrong. The hydroboost I am running is out of a 1995 astro van I assumed it was the same as the the one out of the 1995 chevy 3500 as I am using the power steering lines from the 3500 and the 3500 had Jb8 brakes as well. So I just assumed It would be the same as the 05 3500 just a few slight changes. It turns out the 95 astro and the 95 3500 hydroboost uses a 1.25 bore master cylinder and the 05 3500 uses a 1.456 bore master cylinder, and the 1975 C30 I got the JB8 brakes from uses a 1.312 bore master cylinder. So I thought about returning the master cylinder and just run the 95 3500 as I know it will be a direct bolt on and work with the jb8 brakes. But at 3 am I cant sleep and I don't like the idea of running a smaller bore master than what the original Jb8 system from the 75 c30 had, So I'm thinking how can I make the master cylinder fit My first thought was to bore out the hydroboost but it would make it week as it would be super thin. Then I started researching if any one made an adapter plate. I could not find one, however I came across several on adapting a chevy master cylinder to a toyota brake booster. And it was just a simple spacer with the two bolt patterns. I had thought I had some 1/2 aluminum plate but I didn't. So I got to thinking, I could just use the old astro van master cylinder flange as the the spacer. So I cut it off and milled it down and bored it out to 1.456. its a perfect fit!

IMAG2849

IMAG2849 by

jarrod vanwinkle, on Flickr

IMAG2850

IMAG2850 by

jarrod vanwinkle, on Flickr

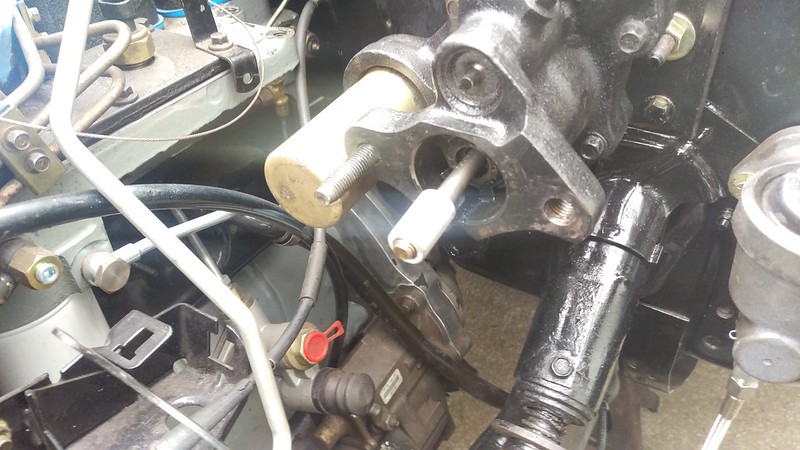

So now the push rod is 1/2 to short. My plan is to use a 3/8 6.5 inch grade 8 bolt and cut it down to work as the push rod. So as a temporary solution and proof of concept I threaded the stock pushrod and a piece of aluminum round bar and cut off the head of a bolt to keep it centered. it works great so the next time I go to town I need to pick up a grade 8 bolt. I had thought of just welding an extension on the pushrod but If i do end up having to use the 95 3500 master I can still use the stock pushrod.

IMAG2848

IMAG2848 by

jarrod vanwinkle, on Flickr

IMAG2851

IMAG2851 by

jarrod vanwinkle, on Flickr

I had to make a new line as the front fitting was different.

IMAG2855

IMAG2855 by

jarrod vanwinkle, on Flickr

Another problem is it maybe to tall but I think it will fit.

IMAG2856

IMAG2856 by

jarrod vanwinkle, on Flickr

The throttle cable linkage end finally showed up.

IMAG2857

IMAG2857 by

jarrod vanwinkle, on Flickr

I also started on the fuel tank lines the valve is for when I upgrade to the 40 gallon tank to make it easier to remove it with fuel in the tank as I made the tank gravity feed.

IMAG2858

IMAG2858 by

jarrod vanwinkle, on Flickr

IMAG2859

IMAG2859 by

jarrod vanwinkle, on Flickr

The 95 3500 power steering line was almost perfect. I just had to bend it very slightly to clear the pump housing.

IMAG2860

IMAG2860 by

jarrod vanwinkle, on Flickr

IMAG2861

IMAG2861 by

jarrod vanwinkle, on Flickr

Now I just need to order some power steering hose and a t fitting for now. I plan on running a power steering cooler and a filter. the filter will also be used as the t fitting as it will have two inlets and one out.