Thanks guys! Greg, I was a bit more slow lane than my norm..

Back when we were shaving all the holes in the firewall, the dimmer switch in the floor actually went THROUGH the floor where the connections were made on the outside, and only the push actuator stuck through the floor. Not wanting anymore electrical connections outside the floor than needed, we welded up the center hole, and kept the floor nuts to bolt the new one inside.. Any never gave it any more thought. Until this weekend. Our dimmer switch, a DS115 has a bolt pattern of about 1.75" between hole centers. The factory nuts are about 2.625" between hole centers. Oh well, back up and punt has become second nature with this project..

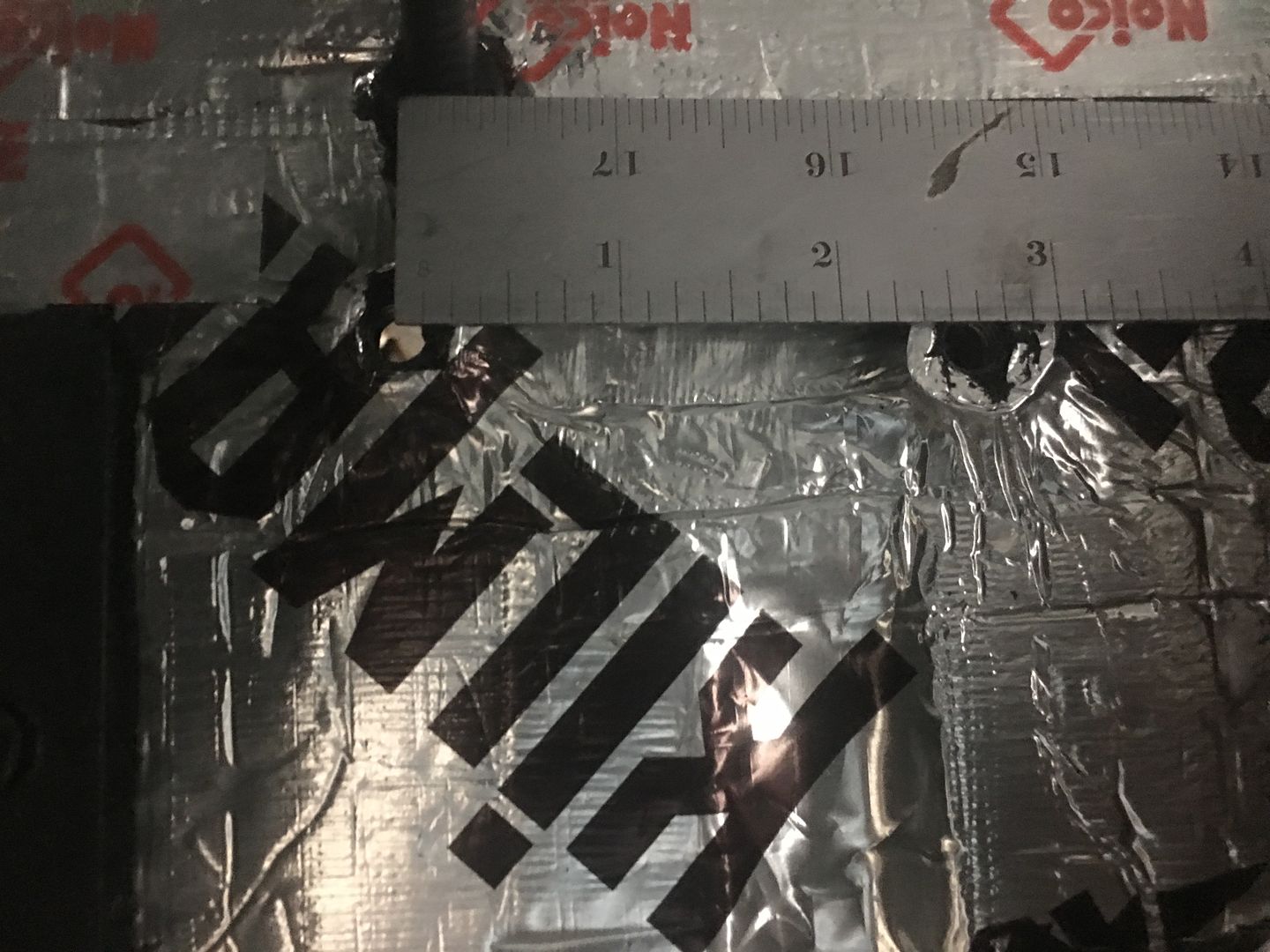

So we started by fabricating an "adapter bracket" using 16 gauge stainless and a 1/4-20 press stud.

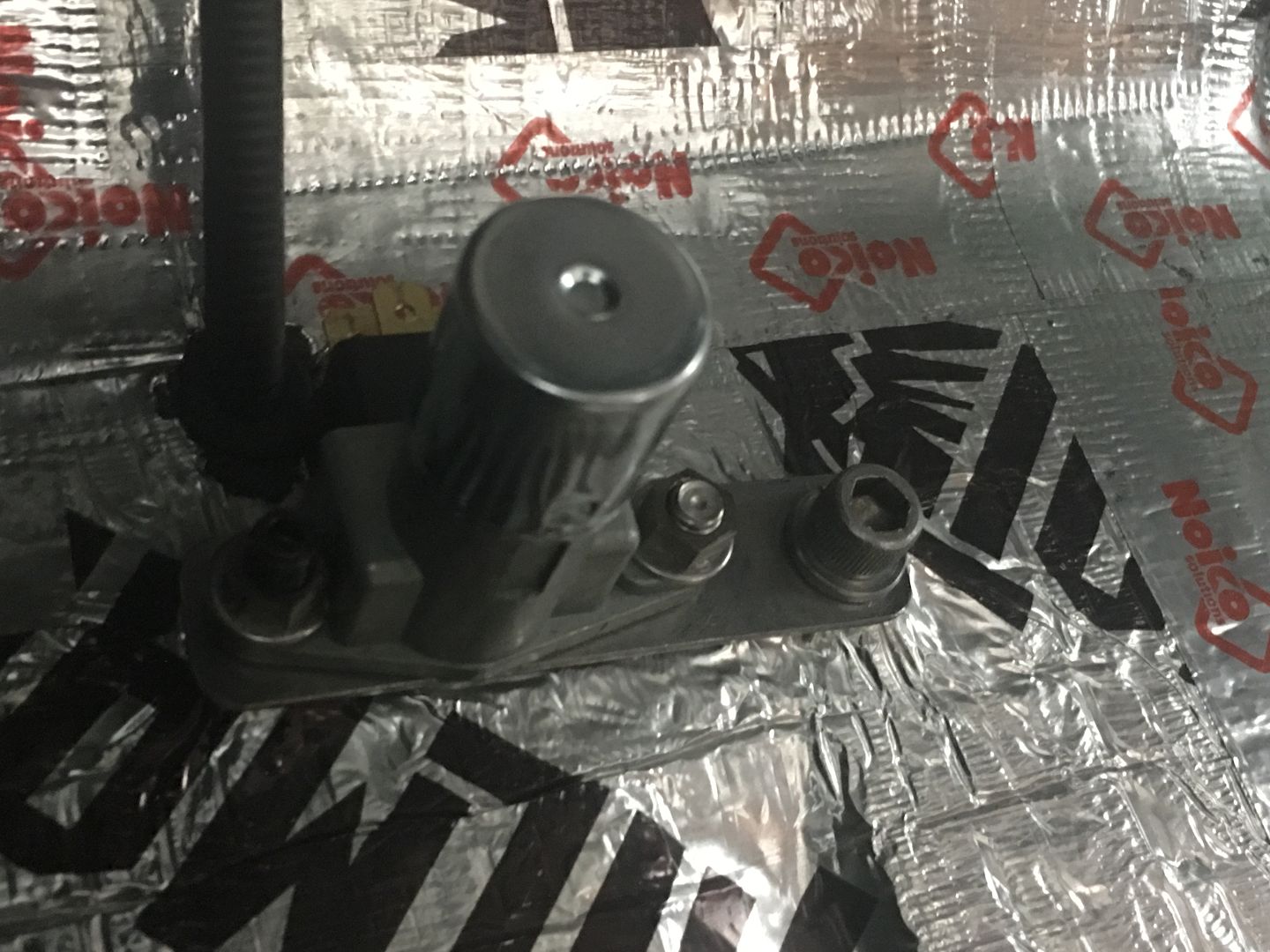

Next, the left bolt needed to be 1/4-20 to fit in the hole of our dimmer switch and with the floor hole at 5/16-18, we need another adapter. So two set screws of appropriate size were welded together, and this allows using an allen wrench to install and hold while tightening the nuts to hold down the dimmer switch.

The right screw remains 5/16-18 through, but we are going to find something with a smaller (shorter) profile for under the carpet.

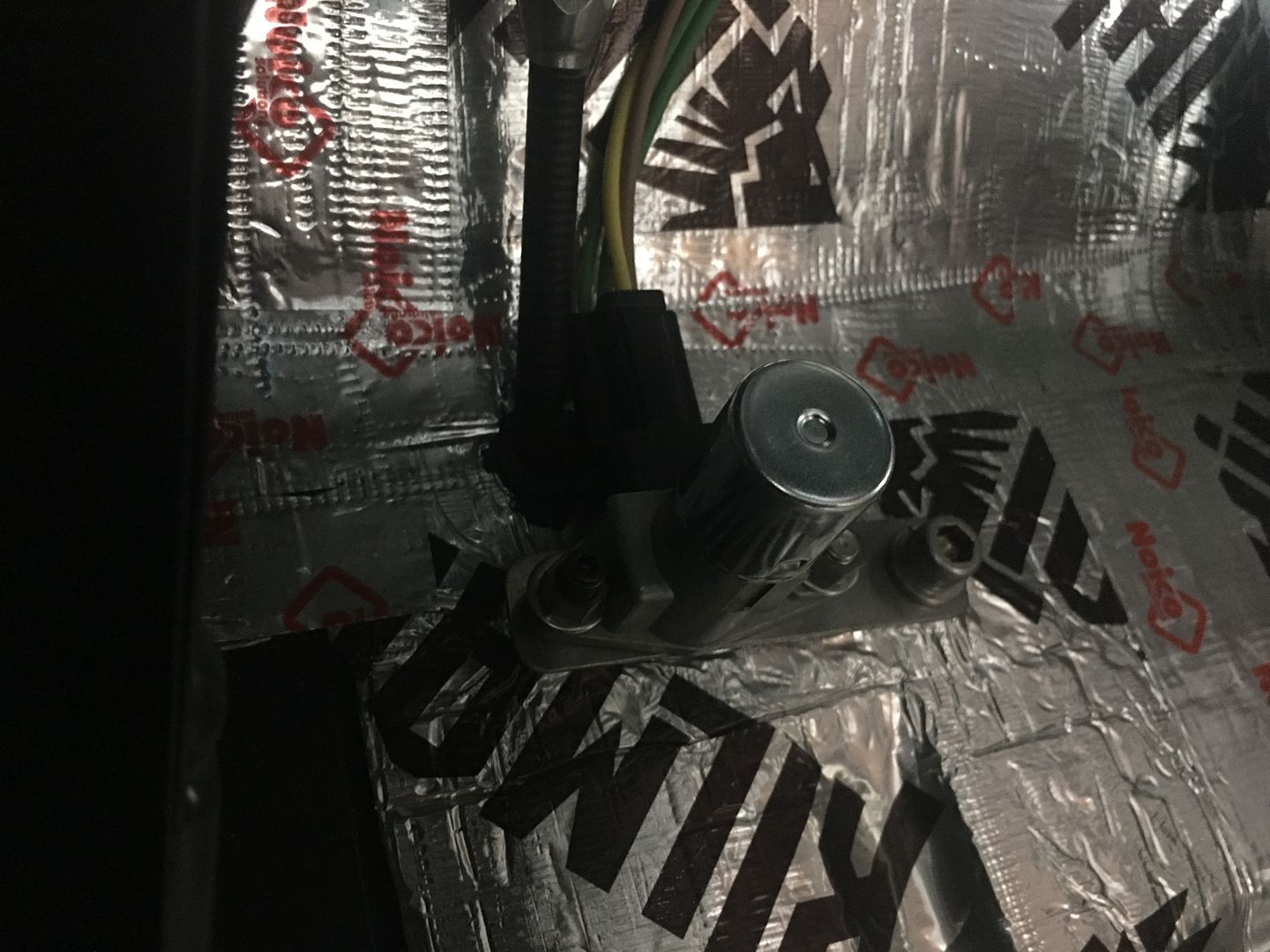

…..with plenty of room for the wiring inside

Mike and Jarod got the fuel tank along with fill and vent tubes installed...

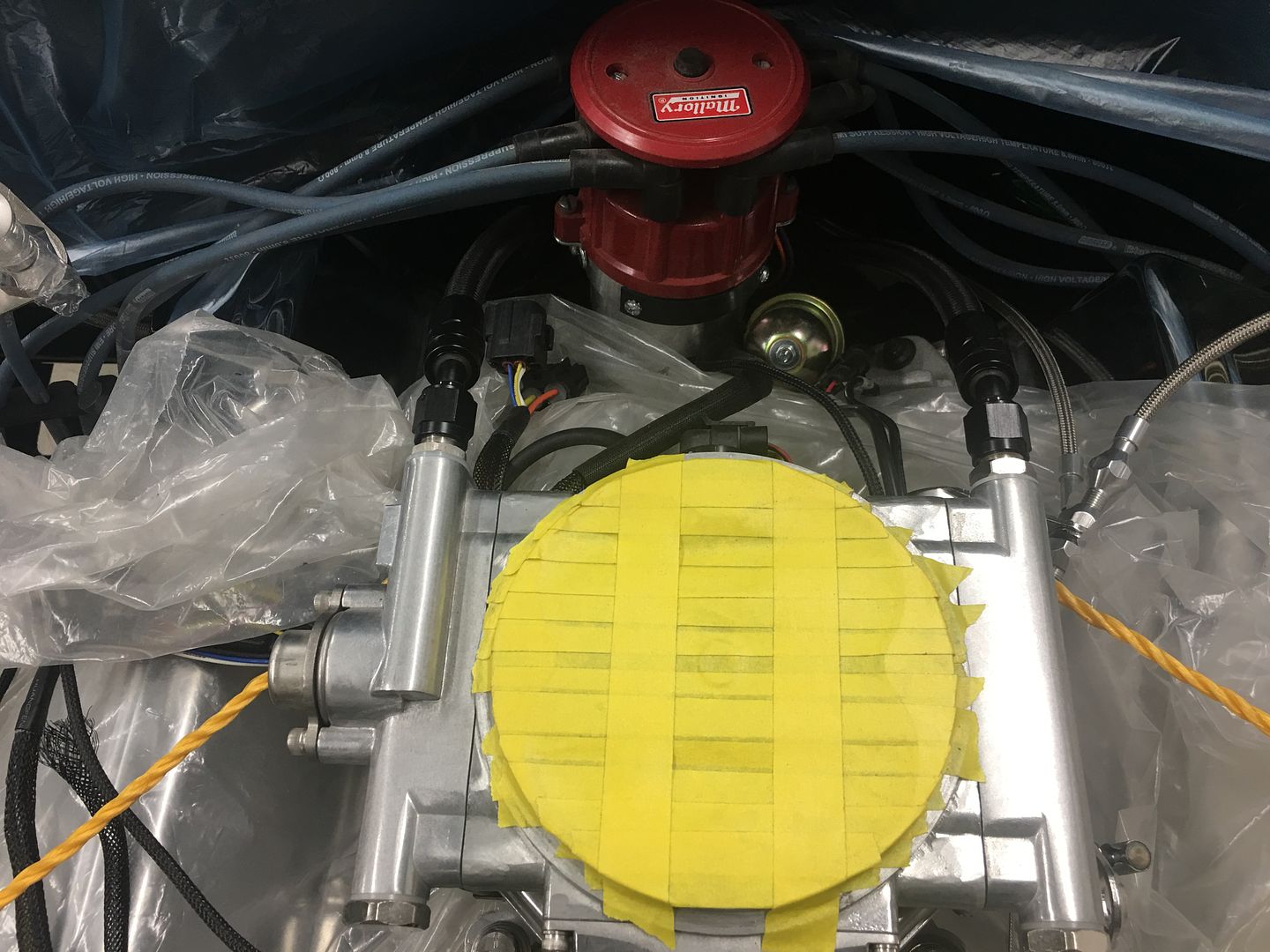

…..and then finished our "flexible" lines from the hard lines on the frame up to the EFI.

We still have clamps to install.. Up at the EFI, 30* fittings were used to give us a downward trajectory but yet high enough to keep off the heat of the intake (that the 45* would have done).