let me answer by clearing something up. MIG gas shields the weld and makes it faster and cleaner,

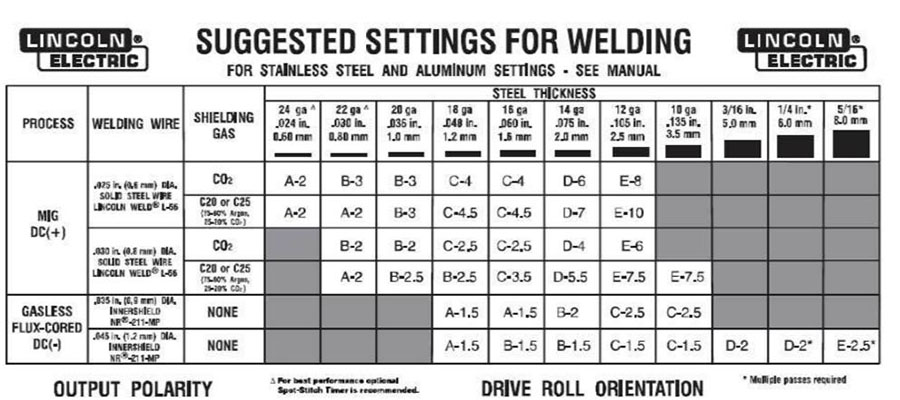

but it also needs more current. "mix" is 75% argon and 25% CO2 is the most common MIG, straight argon is less common. anyone who has gotten a straight argon by mistake instead of mix knows you quickly run out of current, welding takes more power with the 100% argon. its the same way with flux and MIG mix, seen in this welding thickness chart with the two processes.

115v flux can actually be more powerful than 220V MIG, seen by the difference in heat settings. MIG (mix) is better for thinner metal, for sure. which is why my answer was to use flux on your frame and MIG on your panels. But if you try to MIG the frame, you will need more power than likely the machine has. Flux on the frame will be plenty though. Sucks changing wire (and output polarity, dont forget to change that between flux and MIG), but its cheaper than buying a whole new welder.