Thanks for checking out the work!!

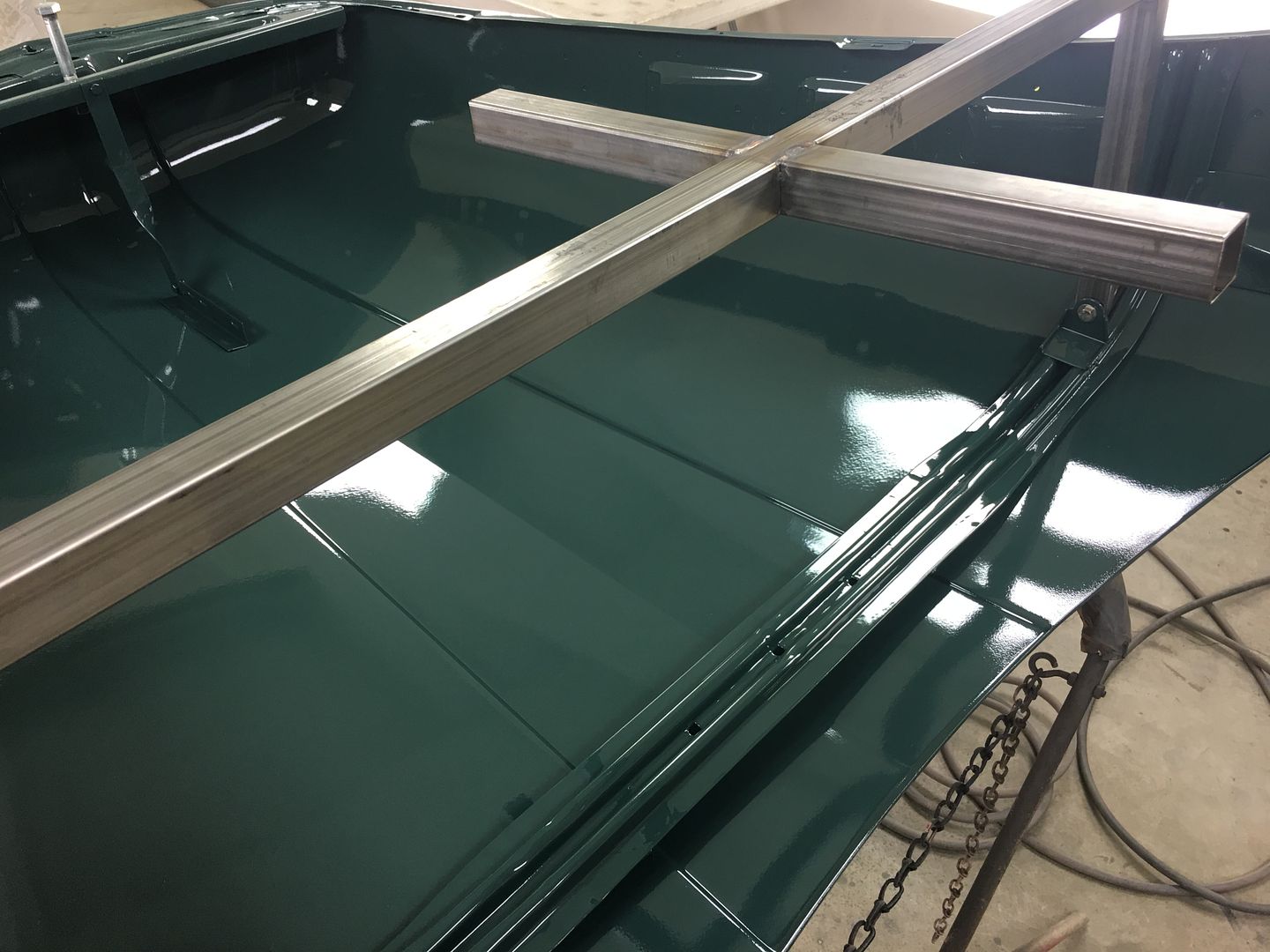

So every time we place the hood on my folding stand, the hood skin deflects upward at those pressure points (corners). Which means that won't work for blocking out the hood. So lets' use the same supports that the hood uses and make a blocking "stand".

Large 5/8" bolt through the hood latch hole for supporting the nose...

And going through our scrap inventory, here's some tubing we used for the back end, bolted into the hinge support. The extra "feet" help to stabilize it so the sanding effort won't try and flop it over...

With that done, all our open holes are taped over and the entire bottom side masked off to protect the inside finish..

A bit of Evercoat 416 to address some lows, and 3 coats of SPI epoxy for the next round of blocking on the outside.

Blocking...

Some booth clean up and fresh masking on the table, hood pre-cleaned and tacked.....

Sealed with SPI Epoxy thinned about 10%

Fleet paint that was used originally on the truck, supplied by owner. Orange peel in a can..

2 coats of color, 2 coats of SPI Universal Clear...