|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#26 |

|

Registered User

Join Date: Dec 2009

Location: Independence Mo

Posts: 4,118

|

Re: Need some help with tuning.

If youre going to use an '05 PCM, then you'll need a 12589462, that should make the 12v A/C request work

__________________

My '72 short bed build. http://www.ls1tech.com/forums/conver...6-0-4l80e.html 5.3 swap into my RUSTY '71 C10 http://ls1tech.com/forums/conversion...71-c-10-a.html |

|

|

|

|

|

#27 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

Quote:

For now, I went ahead & wired in a relay & the A/C works GREAT, 45 degrees out of the center vent, 98 degrees ambient, Head Pressure never got over 250, Low Speed Fans always on, High Speed cycling on & off. Not crazy about not having over pressure protection but, As long as I don't lose a Fan or a Relay.....I should be OK. |

|

|

|

|

|

|

#28 |

|

Registered User

Join Date: Dec 2009

Location: Independence Mo

Posts: 4,118

|

Re: Need some help with tuning.

Yeah, I hear you on that, and honestly don't know for certain that the fans would also work as I almost always use clutch fans. Sorry I couldn't be of more help.

__________________

My '72 short bed build. http://www.ls1tech.com/forums/conver...6-0-4l80e.html 5.3 swap into my RUSTY '71 C10 http://ls1tech.com/forums/conversion...71-c-10-a.html |

|

|

|

|

|

#29 | |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,831

|

Re: Need some help with tuning.

Quote:

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

|

#30 |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,831

|

Re: Need some help with tuning.

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

#31 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

Thanks Rob, I will look into that, If I'm reading that right....They are swapping a F-body A/C segment into a Van PCM (Both being a "411" P01 PCM)? Will this work on P59 PCM's would be the question I suppose?

|

|

|

|

|

|

#32 |

|

Registered User

Join Date: Dec 2009

Location: Independence Mo

Posts: 4,118

|

Re: Need some help with tuning.

The 411 type PCM (P01) from a van is almost the exact same thing as one from a 99-02 camaro so I'm sure that would work, but from my experience the 411 wont work with the newer P59 blue/green PCM tune. I've personally seen a few bricked PCM's from trying to load newer files into older computers and vice versa. I'll be watching this because I'm curious about the outcome.

On a side note, would it be possible to add a high pressure switch in series with the clutch wire somewhere in a high side line?

__________________

My '72 short bed build. http://www.ls1tech.com/forums/conver...6-0-4l80e.html 5.3 swap into my RUSTY '71 C10 http://ls1tech.com/forums/conversion...71-c-10-a.html |

|

|

|

|

|

#33 |

|

meowMEOWmeowMEOW

Join Date: Sep 2009

Location: MKE WI

Posts: 7,128

|

Re: Need some help with tuning.

Usually going backwards bricks things, just a generic rule o thumb.

Really good tip when wanting info in one tune (including non HPT) and into another...get Open Office. You can use a blank spreadsheet and paste-special the data and formatting from the Hpt cells into an external document, then come back and paste into the new tune. You have to be careful that nothing got changed in the translation, but I use this method when making goofy injector scales.

__________________

'66 Short Step / SD Tuned / Big Cam LQ4 / Backhalfed /Built 4l80e / #REBUILDEVERYTHING  |

|

|

|

|

|

#34 | ||

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

Quote:

The other option is Crimping a Inline R12 service port on the Discharge hose.....Removing the Hose Assembly is a PITA on this car. I'm trying too keep "add-on" wiring too a minimum, OCD quirk of mine. As you can see the only port available is the port for the A/C pressure transducer.  Quote:

The question is.......Can I overwrite the 2005 12589463 PCM with the "Tune/Calibration" from the 2004 12586242 PCM?? |

||

|

|

|

|

|

#35 |

|

meowMEOWmeowMEOW

Join Date: Sep 2009

Location: MKE WI

Posts: 7,128

|

Re: Need some help with tuning.

I would just Open Compare File, then open a few of the trans tables and click "differences". That will highlight the cells (or graph area) that are different (in tables that are comparable). Then you can see whats actually functioning differently. Itll highlight green all the areas where differences occur. Then you can view them, and copy the table data from one to the other. Its time consuming, but you'll actually be able to sorta see what the big disparities are. I'm not the most experienced person the planet, but its been my experience that without knowing WHY one worked better than the other, I wouldn't have felt like I solved the problem.

__________________

'66 Short Step / SD Tuned / Big Cam LQ4 / Backhalfed /Built 4l80e / #REBUILDEVERYTHING  Last edited by BR3W CITY; 06-25-2016 at 01:08 AM. |

|

|

|

|

|

#36 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

Quote:

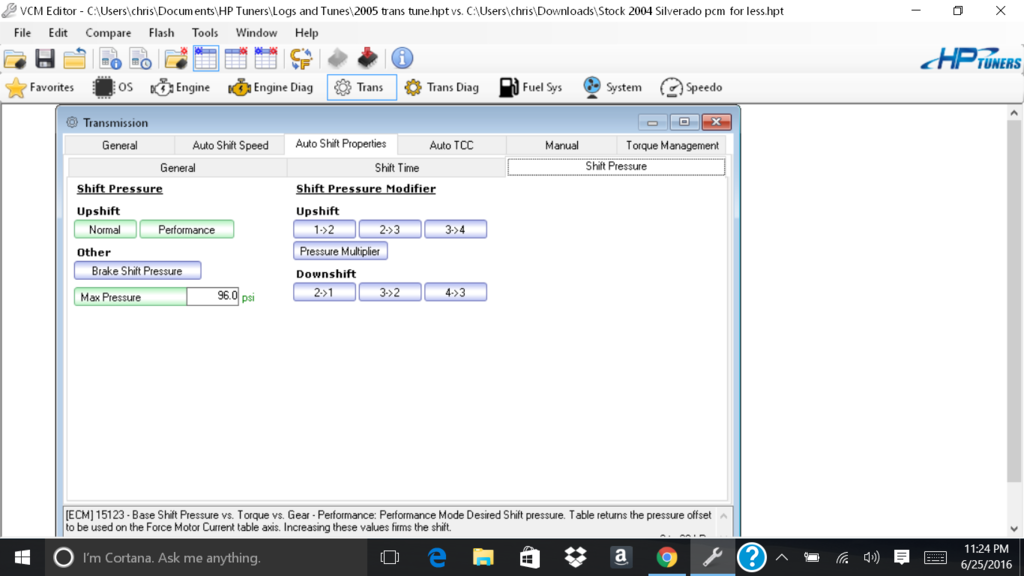

There is one value I cannot change, Max Trans Pressure....Well, I was able to up it 6 PSI, 90 PSI to 96 PSI. My old tune is set too 130 PSI. On a side note.....I don't see how this correlates to real world pressures?? My modified pump & large ratio boost valve can bump 225 PSI easy at WOT.

|

|

|

|

|

|

|

#37 |

|

Registered User

Join Date: Nov 2007

Location: Bay Area, Ca

Posts: 2,841

|

Re: Need some help with tuning.

Look at the attached diagram and tell me if this is how your AC fans are wired? They should be a 3 relay set up is using the f-body analog control.

I just went through this with a buddies car. Provided he was using a vintage air unit, the shop that wired it did not have the 3 relay fan set up, no signal from AC to PCM for idle bump, and I had to run a resistor to bypass the pressure switch safety circuit. This was a great article which I used to help fix his issues: http://www.lsenginediy.com/upgrading...tioning-guide/ It has various pin out assignments, function and even a resistor mod to bypass the pressure switch (which we did in his 73 Camaro).

__________________

------Motor---------------Bottle 60'---1.53---------------1.41 1/8---6.58 @ 105.92----5.87 @ 118.41 1/4---10.38 @ 126.97----9.24 @ 142.49 Last edited by Super73; 06-26-2016 at 02:37 PM. |

|

|

|

|

|

#38 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

I do have the 3 Relay set-up.

Now that I have a PCM with the correct Hardware, The Fans are functioning correctly with the Pressure Transducer. I bumped the A/C off Idle table to the same RPM as the A/C on table, I have a Stall Converter so the higher RPM isn't really an issue. If I'm understanding you correctly, A resistor will make the PCM read a fake fixed value to enable A/C Clutch Relay & Turn the High Speed Fans on anytime A/C is requested? But....Wouldn't that turn the Fans on even without the A/C request because the false refrigerant pressure signal? My issue right now is.....My 2005 PCM will not accept a 12vdc A/C request. |

|

|

|

|

|

#39 |

|

meowMEOWmeowMEOW

Join Date: Sep 2009

Location: MKE WI

Posts: 7,128

|

Re: Need some help with tuning.

Cline I'm bored of fixing A/C problems. Your next post better be about how we need to tune something thats figuratively cool instead of all this literally cool nonsense.

__________________

'66 Short Step / SD Tuned / Big Cam LQ4 / Backhalfed /Built 4l80e / #REBUILDEVERYTHING  |

|

|

|

|

|

#40 | |

|

Registered User

Join Date: Nov 2007

Location: Bay Area, Ca

Posts: 2,841

|

Re: Need some help with tuning.

PCM needs 12v to realize AC is on, or requested on. This is what triggers both fans on LOW speed. Fans are in series through a single relay.

Resistor is only there as a bypass for the pressure switch, in the event you can't tie in to it, or it would be redundant like the vintage air. Quote:

__________________

------Motor---------------Bottle 60'---1.53---------------1.41 1/8---6.58 @ 105.92----5.87 @ 118.41 1/4---10.38 @ 126.97----9.24 @ 142.49 |

|

|

|

|

|

|

#41 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

Quote:

Thanks for the help Brew! |

|

|

|

|

|

|

#42 |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,831

|

Re: Need some help with tuning.

Any updates on your AC problem CB? Just curious as I'm running a Gen IV Vintage Air system and have a Speartech EFI harness in my Suburban (05 PCM). The harness was wired with a factory trinary switch. Am I going to have the same problem that you are having? Also, I'm using the factory truck compressor that came with the engine, how much oil should I put I in it when I charge it up? Is there anything else I need to consider before charging the system? Thanks in advance. Rob

Rob

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

#43 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

Quote:

But my Fans work great! And respond too AC Head Pressure even without a valid AC request. I bumped the AC off Idle Tables up a little (550 vs 525). All in all.....A/C Request is not a big deal & I wouldn't reinvent the wheel just to get it working, I've been driving my car for 3 weeks & have never turned the A/C off  Your situation is a little different than mine.... Install the Vintage Air Binary in the Drier like normal & run your Compressor wire though it......This will give you High & Low pressure protection. LOW is OFF @ 28PSIG - ON @ 29PSIG HIGH is OFF @ 454PSIG - ON @ 369PSIG For the GM Pressure Transducer, It is 10mm/1.25, You will need to add it into the Liquid Line (#6) somewhere, Vintage Air, Old Air etc. don't have a clue what the h-ell your talking about if you call them. But it is very common in industrial/heavy duty applications, Here is an example....http://www.truckerac.com/achofiforgos.html The Transducer will screw right on. You will need to drain the oil out of the GM/Denso Compressor. 2 oz. in the Compressor. 2 oz. in the Condenser. 2 oz. in the Evaporator. 6 oz. total. Use ONLY PAG 46! Required for Denso Compressors!!! If you do not want to drain the Compressor, The Compressor is used & no oil got dumped......There will be "approximately" 2 oz. of oil in the Compressor. 2 oz. in the Condenser. 2 oz. in the Evaporator. Keep in mind this is guessing & I do not like it!! If this is a NEW GM/Denso....It will come charged with 8 oz. of PAG 46. Read the paper work to confirm, Drain 2 oz. out & do not distribute oil anywhere else. |

|

|

|

|

|

|

#44 | |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,831

|

Re: Need some help with tuning.

Quote:

I installed the pressure/transducer switch in the high pressure line with the fitting you suggested, but I'm confused. It's a 3 wire switch, so I assumed it was a trinary switch similar to the one you can purchase from Vintage air. Is that incorrect? I wired the a/c "on" signal from the Vintage Air unit to a green wire from my Speartech EFI harness that was labeled a/c request. I just assumed the pressure transducer handled everything else. As far as the compressor, it's virtually brand new as the motor and transmission only have 10 miles on them. However, neither have been started in 10 years.....sooooo...WWCBD?  Thanks for the info - Rob EDIT: Perhaps I need to ask more questions and give more info: (keep in mind that I have not started the truck yet....  ) )1) Is my compressor analog or cycling (its from a 2005/6 Tahoe) 2) I used part number 95018104, is that a pressure switch or pressure transducer? 3) It has 3 wires that go to it, what functions does/should it provide? 4) My EFI harness has a plug that fits into the compressor, has one for the 95018104 switch/transducer that I installed into the liquid line, and an AC request wire that I connected to the Vintage Air a/c request signal wire. So, should I have a high and low protection? Should the fan(s) come on when I turn the a/c on or when head pressure goes high? 5) Did I just totally blow up your thread and do you want me to start another one??????   To throw more fuel on the fire, I found this thread on LS1Tech: http://ls1tech.com/forums/conversion...ector-ecu.html

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 Last edited by Hart_Rod; 09-13-2016 at 10:14 AM. |

|

|

|

|

|

|

#45 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

This thread was dead anyway.....Doesn't bother me at all Rob.

It is NOT a Trinary, The Transducer sends a 0-5vdc signal too the PCM & is read as Actual/Real Time A/C Head Pressure, The PCM will control the Fans per Pressure & disable them above a certain speed, You can change all these settings with HPT's. A '05 GMT800 P59 is "Serial Cycling" from the factory, Meaning the HVAC Control head not only sends a Serial A/C Request, But can also send A/C Clutch Cycling Requests over the Serial Data Line as well (Low Pressure Cycling) because the Low Pressure Switch is wired to the Control Head not the PCM. High Pressure Cut-Out is based on Transducer Readings. The thread you linked too mentions Van PCM's, They are Analog Cycling, The Control Head sends a 12vdc A/C Request, A simple High Pressure cut out switch is wired inline & interrupts the Request if pressure is too high. The Low Pressure Switch is wired to the PCM directly. Analog.....Was used on 4th gen F-Bodies, No Low Pressure Switches as the Compressors are a Variable Design, PCM can turn the Compressor off is Transducer/AC Head Pressure is too high. Serial.....Corvettes, CTS-V etc. All the above "Settings/Type Fitted" cannot be actually changed with HPT's, It's Hardware......Tuning Software has no effect. The ONLY PCM I know of that accepts a 12vdc A/C Request & Control the Fans via Transducer input is "0411" PCM's from '99-'02 F-Bodies But those won't work with our DBW set-up. Unless John Spears has figured out how too do this with a GMT800 P59 PCM, The 12vdc you have on the A/C Request wire will not prompt the PCM too ground your Compressor Clutch Relay (Did John flash your PCM?) Back to the Van P59's, They do accept a 12vdc A/C Request, And will ground the A/C Clutch Relay (With the Low Pressure Input grounded), But WILL NOT operate the Fans per Transducer Input! '03 & '04 GMT800 P59's do not accept a 12vdc A/C Request nor will they Operate the Fans per Pressure. '05, '06, & '07 Classic GMT P59's do not accept a 12vdc Request, But WILL operate the Fans per Pressure. |

|

|

|

|

|

#46 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

Rob, Have you tested the A/C Request? While watching A/C Request PID on your scanner, Turn the Vintage Air on & see if it changes from "No" to "Yes". Check for 12vdc on the Request Wire if still "No".

If we can't get a valid Request, No need in leaving it wired the way it is now. Recap if the Request doesn't work out..... Vintage Air Compressor Clutch wire too the VA Binary, Binary too the Compressor. Will provide High & Low Pressure protection. The Transducer & PCM will provide Fan Control as needed. Up the Base Idle as needed, This can get weird with a stock stall converter upon decal to a stop. The PCM's seem to "learn" & act right after a few miles. I'm sure a good tune could correct this. Your Compressor should have around 2 oz in it, This is just an average based on my experience servicing GMT800 Trucks. If I decided to go this route, I'd be concerned about using Too Much Oil! And would add 3 to 3 1/2 ounces, The Denso Compressor is VERY good design & can cope with a little less oil, Where too much oil will affect A/C performance.....More so with aftermarket units. I would (If it were mine) Drain & Flush the Compressor. Use High Volatility/Flammable/No Residue A/C Flush, The good stuff, Kills baby Seals & such. While turning the Compressor....Flush all the residual oil out. Add 6 ounces of PAG 46 too the Compressor, After installed, Spin it at least 20 times. Deep Vacuum for at least 12 hours. Start with 28 ounces of 134a, You will probably end up with 2-2.25 pounds to get maximum chill. |

|

|

|

|

|

#47 | |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,831

|

Re: Need some help with tuning.

Quote:

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

|

#48 |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,831

|

Re: Need some help with tuning.

OK, I checked HPTuners and no a/c request when I turned the AC on via the Vintage air switch,

. However, I did verify that the compressor clutch is receiving power when I turn the system on. . However, I did verify that the compressor clutch is receiving power when I turn the system on. My setup: OPERATING SYSTEM: 12587811 AC HARDWARE SETTINGS: Recirculation fitted: #2 fan Type Fitted: Serial Does this look correct? It's what was in the factory tune when I first read the computer. I think at this point, I may need to wait until the truck running before I can check out the operation of the entire system.

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

#49 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: Need some help with tuning.

Not sure how your harness is wired, But obviously not like factory.....

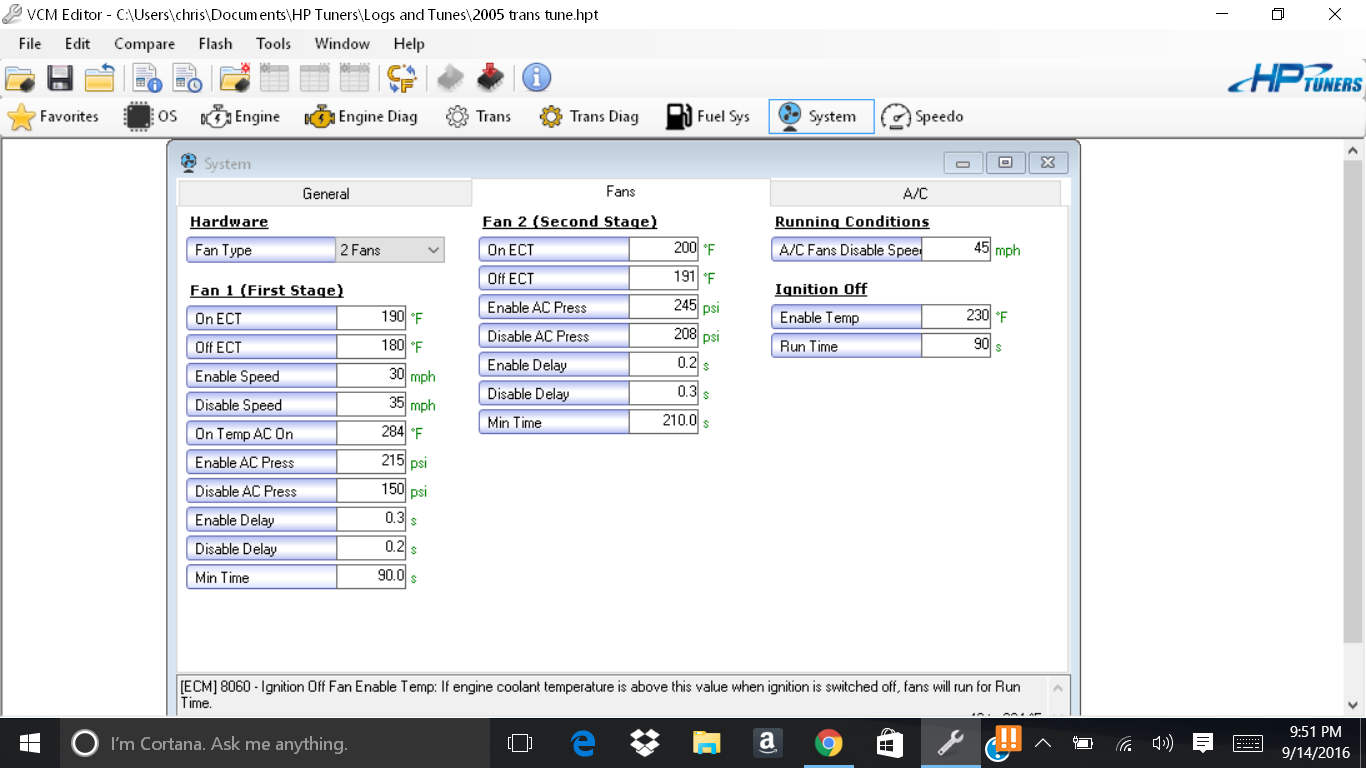

I'm going to guess they branched the A/C Request wire to feed the PCM (Green(C2) Pin 17) & the Compressor Clutch? You can OHM Pin 17 to the Clutch power wire to confirm my suspicions. I made a mistake in my earlier post, A '05 GMT800 is Serial, Serial Cycling would have a Low Pressure Switch wired to the PCM. Set it to Analog & retest.....If no go, Set it too Analog Cycling. If we can just get a Valid Request....Everything else will fall into place. You need too redo your A/C pressure vs Fan Enable settings, The way they are now is for Dual 15" Fans that come stock on '05 & up GMT800's.....They move a ton of air even at half speed. I doubt your aftermarket fans pull close to the same CFM. Here is how mine are set......

|

|

|

|

|

|

#50 |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,831

|

Re: Need some help with tuning.

Quote:

Chris, I changed the fans/pressure settings as you suggested and then tried the Analog/Analog cycling and no go on the AC request signal. I'm starting to think that the green "ac request" wire in the EFI harness is just a pass through that Speartech put in the harness. I do know it will light up a test light at the compressor plug when I trigger the clutch via the Vintage Air controls. I'll try to ohm it out tomorrow. What readings should I expect, "0"? Thanks again for the help. Rob

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

| Bookmarks |

|

|