Possibly did more modification/re-design than was needed

The stock emergency brake was wore out and needed to be replaced and it all started in small steps of modification till I ended up with what you will see below

It all started with picking up a complete parking brake cable set from Inline Tube (E-Strength cables) part number BST6901 Stainless Steel. Installing it in the stock configuration and seeing a few small things that I decided to address.

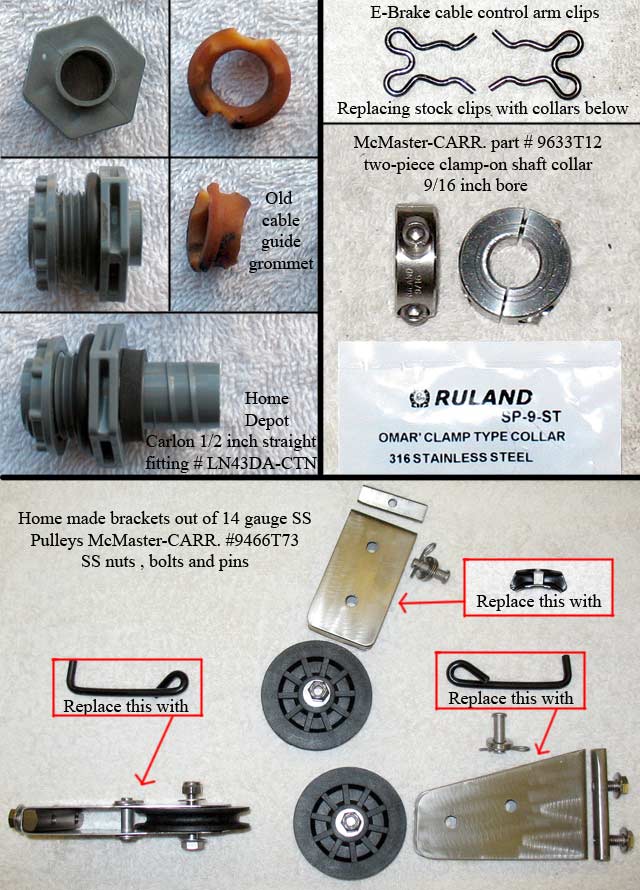

The stock cable guide grommet needed to be replaced didnít look to hard on the internet to find a stock replacement when I ran across what I would call a suitable substitute down at Home Depot in a conduit fitting that will work with minor modification. (see picture below)

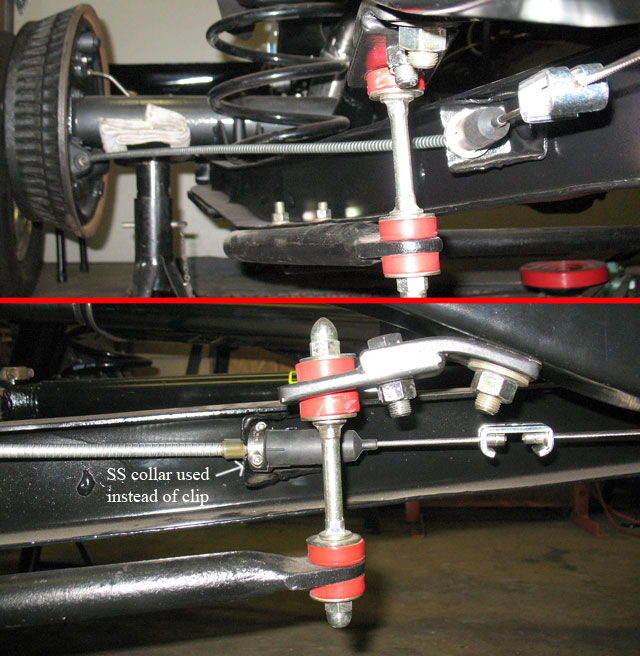

One of the cable control arm bracket clips was missing on the old cable when I took it apart. I can see why because the clips on the new cables didnít hold the cable end in the brackets very good. With the cable having a bend to go out to the backing plate the clip looked like it was at the point where it would pop out of the groove. Found some stainless steel two-piece clamp-on shaft collars that would hold the cable housing flush to the bracket and secure. For those that might want to use the collars instead of the clips, I did have to remove about 1/16 of a inch on the collars width so the rubber boot would fit and I would install the collar on the cable housing at the bracket before running the cable out to the backing plate.

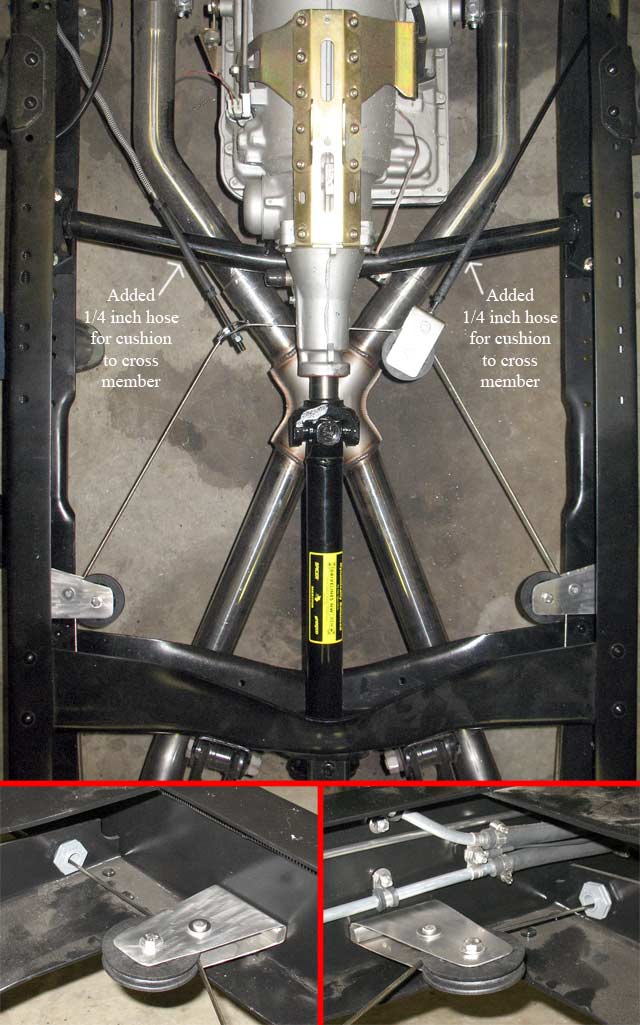

Where the cable and tension rod go over the transmission cross member it was just steel to steel contact, this is normal regardless what cross member you use. But I donít like to see steel to steel contact on moving parts normally in this situation, so I put some ľ hose that I split to get over the cable and tension rod at this point to give it a little cushion.

The E-Brake cable system configuration has been working well for years on our trucks with the guide rods and cable slip fittings. Iíve seen on other vehicles where they have used pulleys instead and decided to incorporate some hear. Fabricated some pulley brackets out of some 14 gauge stainless steel and picked up some pulleys from McMaster-CARR. Ill let you decide if this is a little bit of an over design to the system, because itís just a pickup, but I donít mind being different (smile).

Finished adding some accessories to the engine like the alternator, power steering pump, pulleys, fan, starter, and trans cooler lines.

Items/part numbers not called out prior on this build thread

1318 Ė 18 inch Flex Fan by Flex-a-lite

3509-GR Ė GM High Performance Gear Reduction Starter from ENOS Custom Components

(This starter is for a auto trans with a 153 tooth ring gear)

(Another part number for this starter #6470)

CTT7105 Ė 700R4 Trans cooler lines from Inline Tube

(Lines have been modified to fit my needs)

Just a tip put a little white paint line at the 0 degree point on the damper it definitely helps in setting the timing. Especially for some one like me with old eyes (smile)

I made a bracket at the front of the engine to support the trans cooler lines and cut them shorter and will be using some rubber tube to connect to the cooler lines on the radiator.

The gear reduction starter is smaller in diameter than a stock starter and because Iím using a 153 tooth ring gear theirs plenty of clearance between the starter and the block and exhaust (a help in preventing starting problems from a hot starter). They also make one of theses starters for a 168 tooth ring gear that is probably more common trans flex plate. The one down side to this starter is that itís not recommended for engines with a compression ratio above 9 to 1.

Iím as far along with all the things that can be installed on the frame with out installing the body. Itís been a nice little break from working on the cab but Ill be back working on the cab finishing up some small items before itís sent off to body and paint.

I havenít finalized who is going to do the body and paint. Still looking for some one and any recommendations from forum members in the Everett, WA area would be appreciated. Personal recommendations would defiantly be an advantage. Not looking for the cheapest or a totally custom body and paint somewhere in between.

Enjoy Your Build