Well Iíve decided to abandon the skinny windshield trim project. I prefer the beefier looking trim from the 60-61 trucks, and the larger trim would be much easier to repair having more open space on the back side. So Iím going to shut down until I find a good set of wide trim, or learn to find happiness with the black rubber gasket.

For me, the thin trim just isnít enough of an improvement to warrant the work required or the risks involved with changing the windshield. Before I quit however I wanted to see how the first dent I removed looked after being polished. I sanded it with 600 grit wet, followed by 800, 1000, and 1500.

Moving to the buffer the surface was cut with Harbor Freight green cutting compound on a spiral wheel. A second pass with grey polishing compound on a loose cotton buff, was followed by white compound on a loose flannel buff. Here are the results.

The light reflection across the top of this first shot is from a twin tube fluorescent shop light directly above the trim. The white stripe on the right side is another shop light. The round light between them is a bare ceiling bulb. The dull area on the left is unpolished:

This shot again shows the unpolished area on the left, and the finished/polished repair right in the center of the photo:

This is probably the best reflection I could capture. Itís pretty hard to photograph a shine, but the comparison between the unpolished and shiny portions are readily apparent. The first light reflection near the center is looking down the length of the shop light over the clean bench on the far side of the garage, and the two lights on the right side are two ceiling lights. The dark reflection under the center light bulb is the upper cab of my truck. The image is distorted due to curvature of the surface, but it does indicate the level of shiny reflection:

Iím glad I at least polished up the biggest repair because it does convince me the process works well and can produce show quality results with enough enthusiasm.

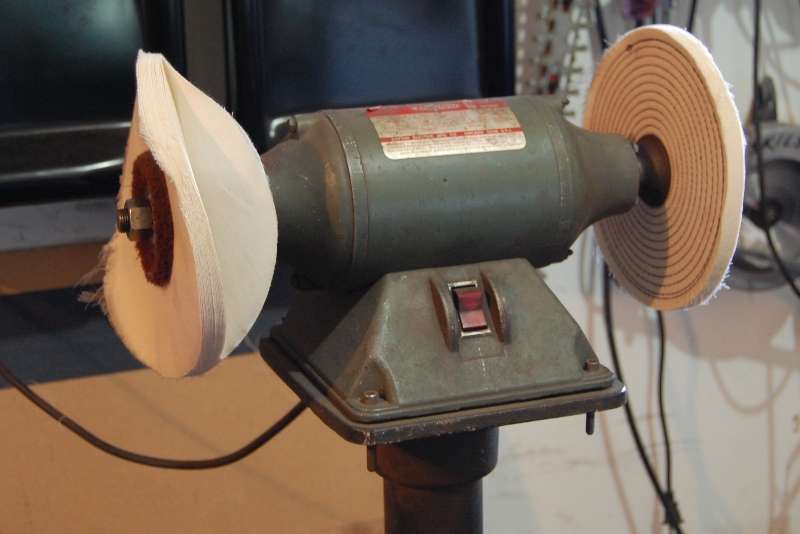

One final note Ė Harbor Freight polishing compounds seem to do a decent job, but the same cannot always be said for their buffing wheels. The spiral wheel and the cotton buff were badly out of round. Only a small portion of the facing surface ever touched the part I was polishing. The flannel buff turned out to be concentric with the hub hole and worked rather well, but the other two caused such tremendous vibration I had to keep my foot on the stand to keep the buffer in one place. And it weighs about 100 pounds and is sitting on top of a rubber floor pad.

Previously I had been using my sonís commercial quality buffing wheels and the performance difference is like night and day. Here are the worst two wheels after less than 5 minutes of use. They are so non-concentric almost 3/4 of the face remains untouched, and the loose wheel on the left is already coming apart from centrifugal force. These are rated for 3600 rpms. The data plate on the buffer Iím using indicates an operating speed of 3450, and a statement ďuse with wheels rated at 3600 rpmĒ:

Sometimes you do indeed get what you pay for!