I've been asked for more details on the side markers.

First I marked out the location.

Then I cut out a hole with a cut off wheel like this.

Then used a die grinder to open up the corners to prevent tearing.

Then reached behind the bedside with the back half of the form, aligned one bolt for starters.

Then aligned all the bolts. Stood back and carefully checked to make sure the form was straight and I wasn't going to press it in crooked.

Then slowly tighten the bolts evenly.

Until it is bottomed out.

Then remove the form and clean up the hole like it originally was.

Install the light to complete the process.

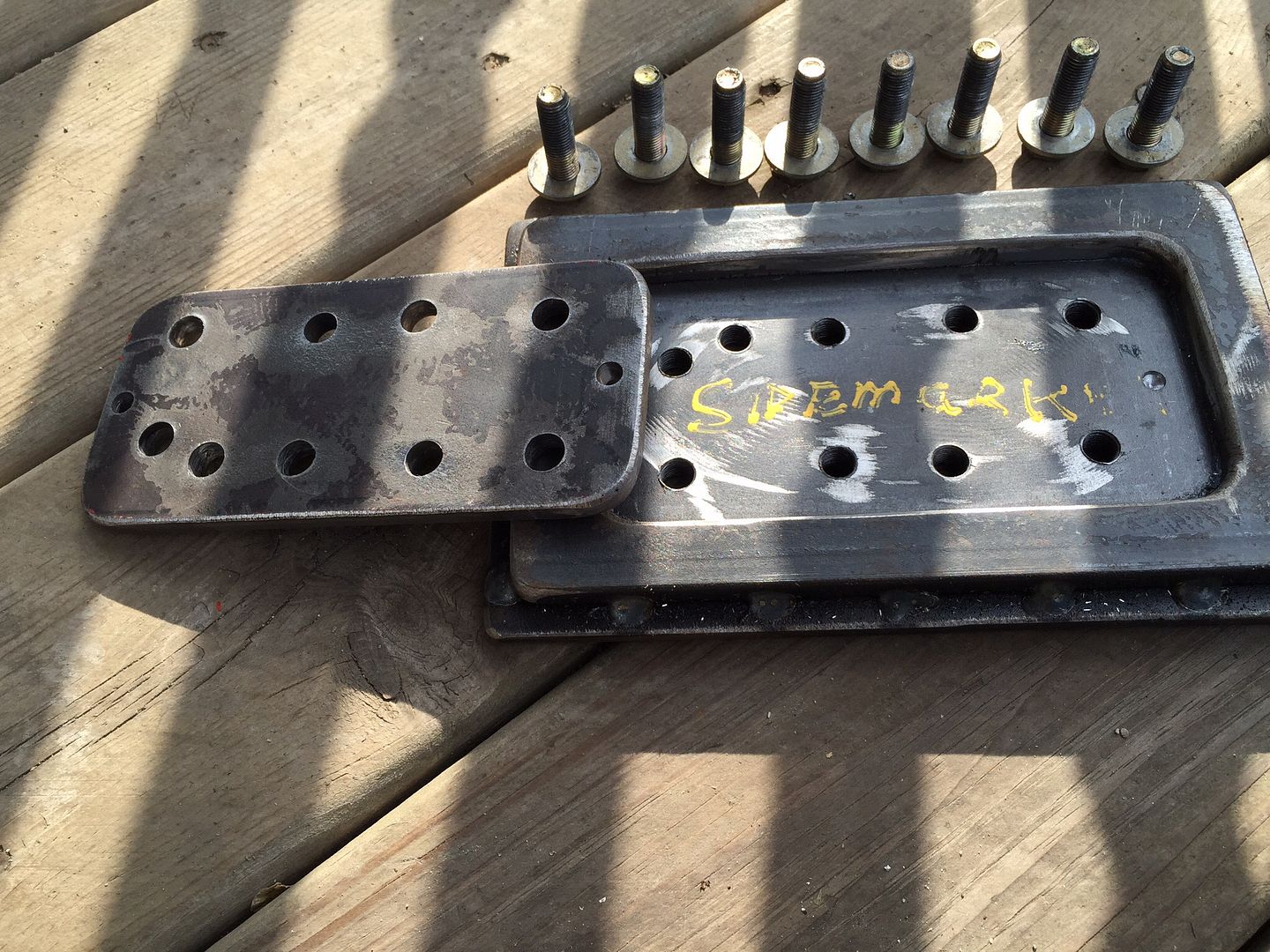

Here are some pictures of the form I quickly made at work.

Im more than willing to lend to form out to any member than needs to use it...