Crank is Yanked. Wow if feels like I am over the hump and things are starting to go back together. Thanks to Dave Myers out at Yank converters, I had the proper converter sent to me within a week. As previously mentioned the first converter they sent me was for a 4L60E, and after numerous attempts I could not get the converter to set into the pump splines. Well the new one dropped right in on the first attempt!!!!

[/URL]

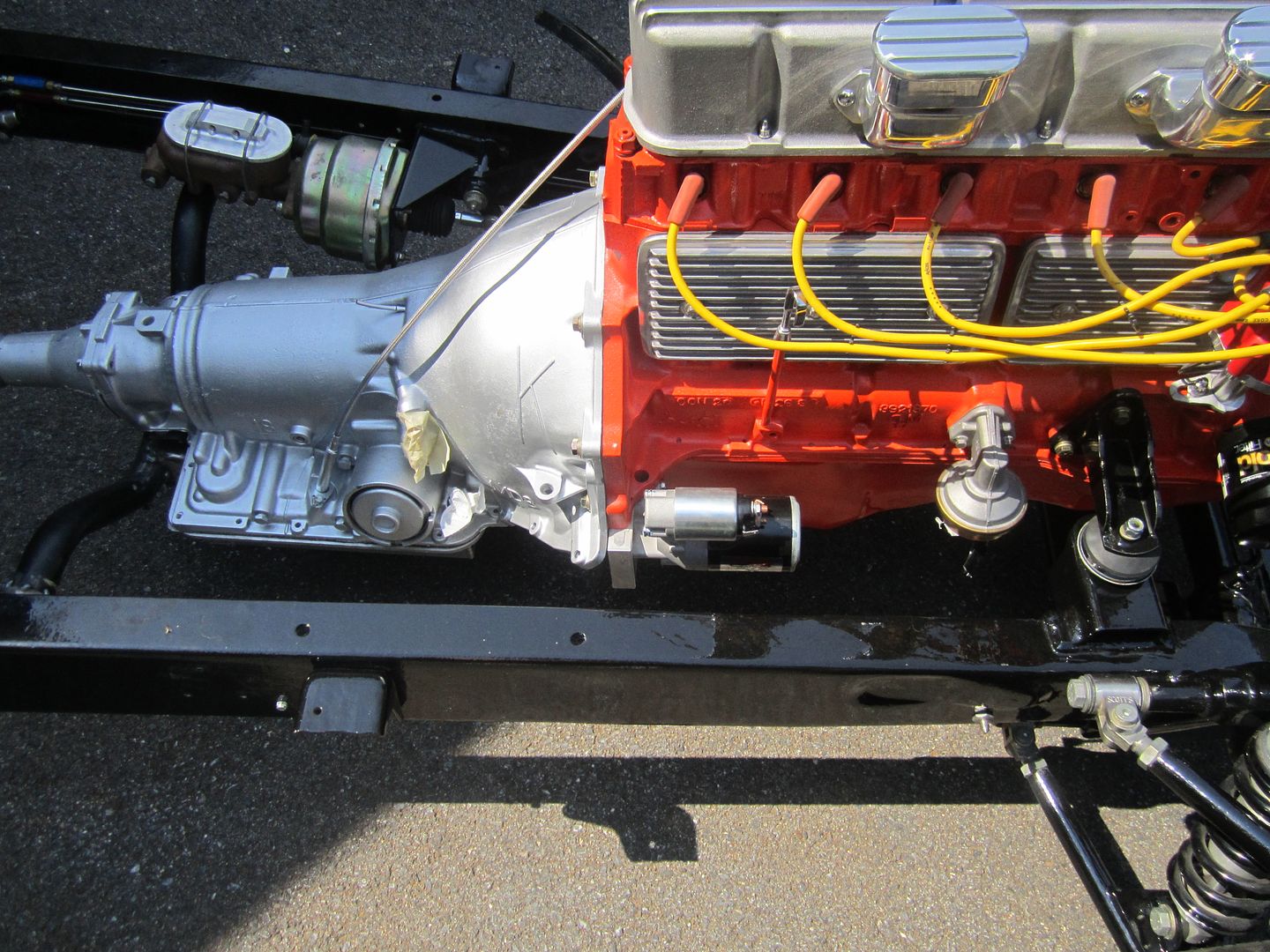

So that meant I was able to free up a lot of space in the garage by getting the motor in!!!!!!!!!!!!

[/URL]

[/URL]

There's a lot of talk about just how to get a flex plate, state and auto trans hooked up to an inline six. Here's how I did it. My motor is from a 70 or 71 milk truck which meant I had the larger 1/2" crank flange holes. So I took a TCI 168 tooth dual pattern flex plate and had the motor shop open up the 7/16 the hole to the proper size. Then I used a CSR mini starter with the straight across bolt pattern. Done!

[/URL]

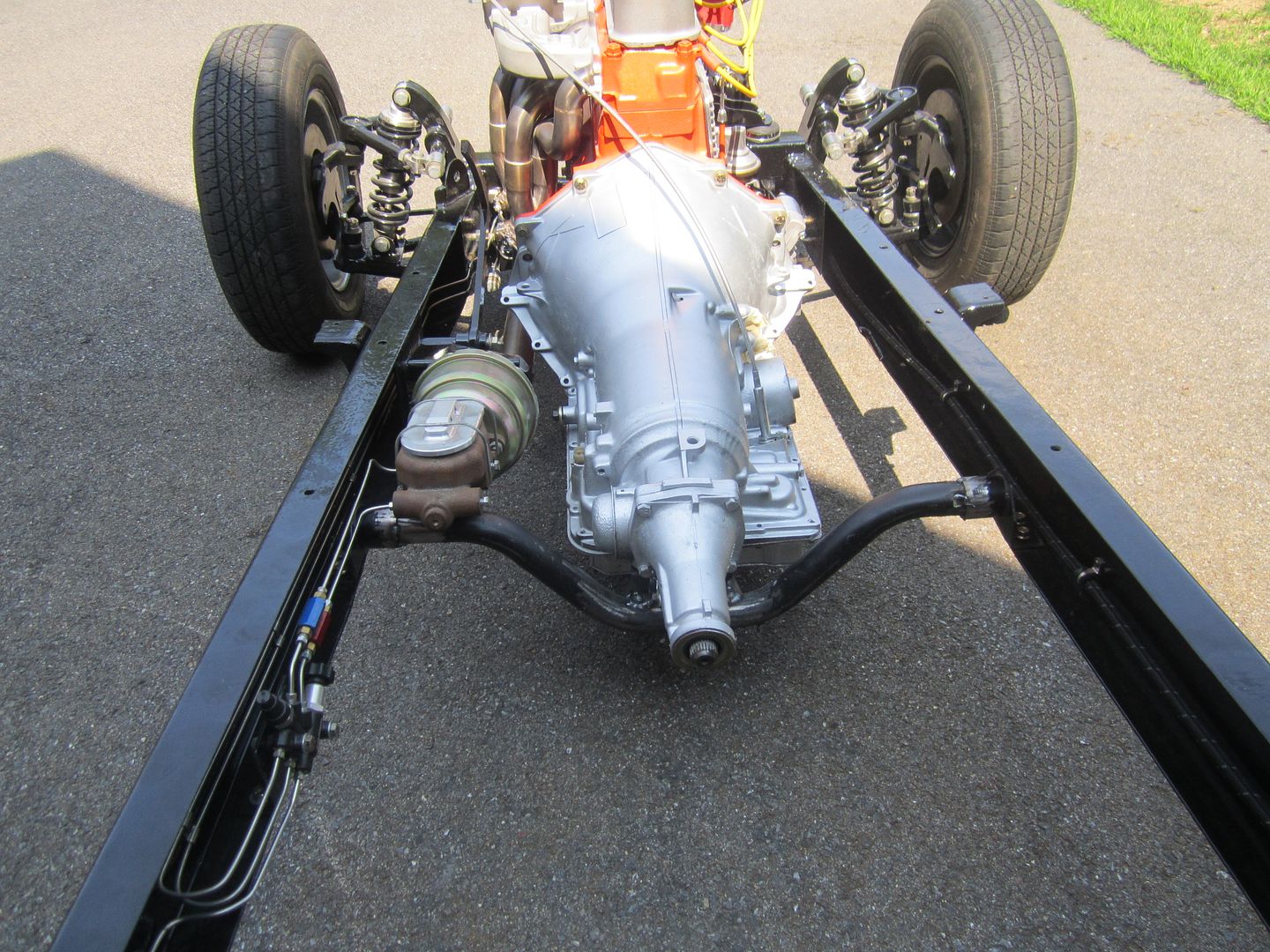

The other hurdle I had to overcome was the tranny cross member. When I was doing the mock up of the motor mounts I just couldn't find a cross member with the right drop and fit I wanted to get the correct angle of the drive shaft. After crawling under the truck a 100 times with the cab on,just to be frustrated, I figured I would deal with the problem when I was at this stage.

So I ended up chopping up 2 cross members that I had laying around to make the one I wanted. This one will give me the 3 degrees down angle on the motor, clears the master cylinder (with a wack from a big hammer

), and gives me a nice opening to run my exhaust pipes through.

I know the cross member looks to low to the ground in this pic but it's just the angle of the photo. I actual have about 10 inches of clearance.

[/URL]

The other hurdle I have to overcome is the header pipe that go under the oil pan to the passenger side of the truck. When I did the mock up I used a 250 block assuming that is what I was going to use. Then I landed the 292 after I had the pipes made. Seeing as how the block is 2" taller on the 292 and the oil pan is different, it means I have a bit of a clearance issue with the pipe and oil pan. The pipe doesn't hit the pan it's just real close (about an inch of clearance) it will work it's just kind of close and I am concerned with the heat from the pipe getting the oil in the pan to hot. I guess I will just get a new pipe made. maybe I am over thinking it.

[/URL]

Now that the motor is in, I now have a bunch of work I can get done.

Trans cooler and lines

Shorten, or get a new drive shaft made

Power steering and Alt brackets........Which may be a big issue.

meanwhile putty, block sand, putty, block sand, putty, block sand.....................