I've been working out a way to cleanly make the curved beads at the front of the trunk panel. Just rolling them into the panel badly distorts the curve since the "base" of the bead needs to be longer than the flat part of the curve.

To make the bottom longer, I made a linear stretch die for the planishing hammer. This allowed me to stretch the metal along the length of the bead without doing as much stretching from left to right.

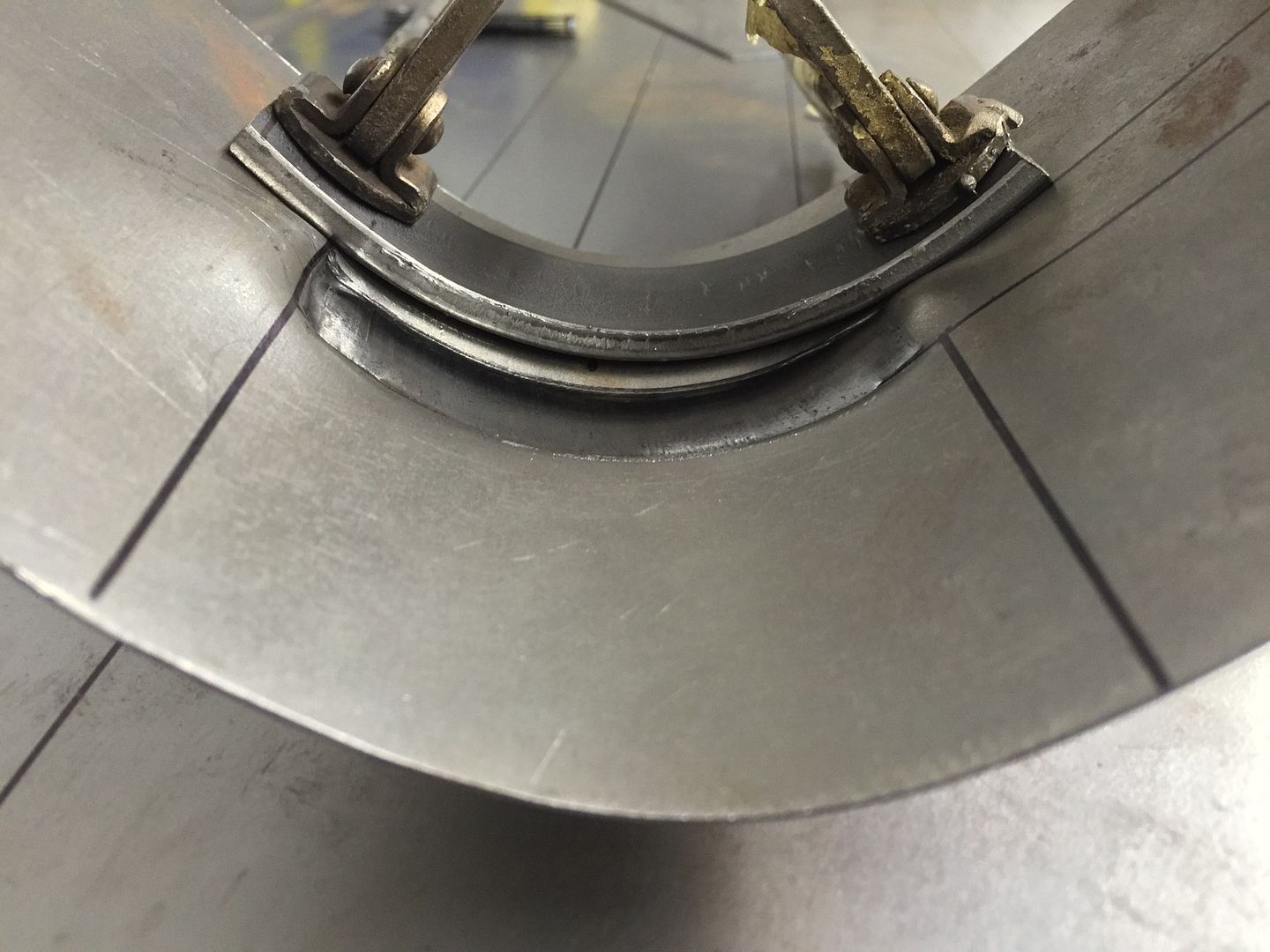

I bent a strip of thick steel to use a guide and clamped it in place on a test panel.

After stretching:

The curve of the panel stayed flat. This was badly distorted if I just ran the bead roller dies up the curved section.

After beading the flat section using the bead roller, and also continuing up the curve to shape the stretched area to match. No distortion around the bead. Still needs some fine tuning but it's better than my first attempt.