Gentlemen,

Thank you for the kind words.

Anyway. Because I am a numpty the chances of hitting my 9th April deadline is pretty close to zero.

Why? You ask dear reader, well let me tell you.

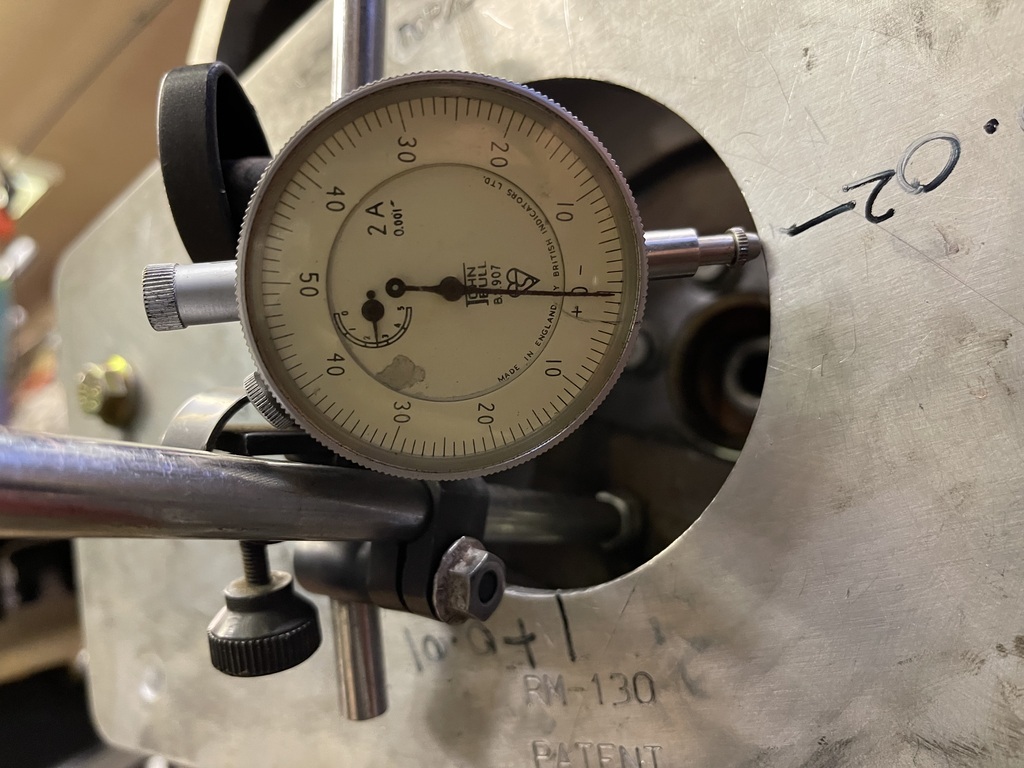

The Tremec gearbox people make a big thing about ensuring that the bell housing run out is within 005". If you think about it makes sense as there is zero run out in the front bearing meaning that if it is misaligned then there is going to be undue pressure on the bearing which, in turn is going to lead to failure and, apparently, difficult shifting.

Because I just didn't think about it (remember that phrase...) I had not ordered an indexing plate that makes the process of checking the run out possible. A T56 is not like the old T10's etc that I am more used too in so much as there is not a nice hole in the middle of the bell housing.

A picture paints etc....

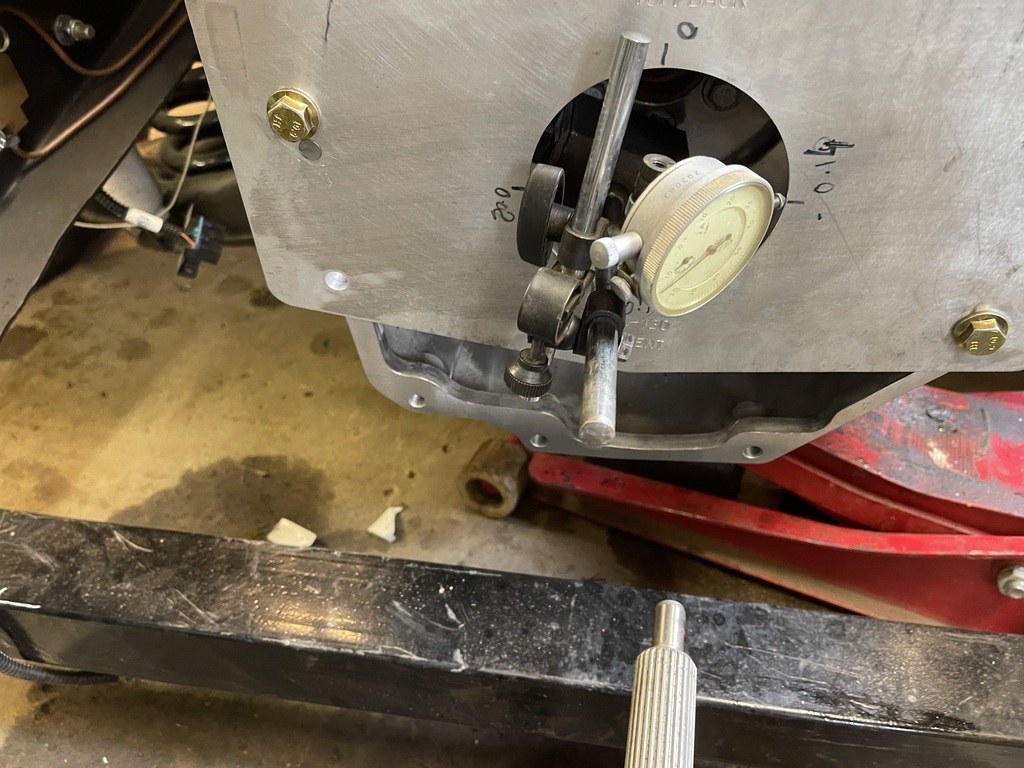

So the indexing plate bolts across the mammoth opening to give that nice circle that you can measure.

Stick a dial gauge on the flywheel and rotate the engine 90 degrees to give the concentricity of the bell housing to the back of the engine.

Like this.

As mentioned above, maximum run out is 0.005"

Mine was a little out.

To adjust the concentricity so that it is within spec you use offset engine dowels, Mine showed that I needed 0.07" dowels.

Now, if I had though about is (see above) I would have ordered a number of dowels with the indexing plate but, because I didn't think about it (also see above), I had to wait another 7 days for them to be delivered from Summit. Numpty.

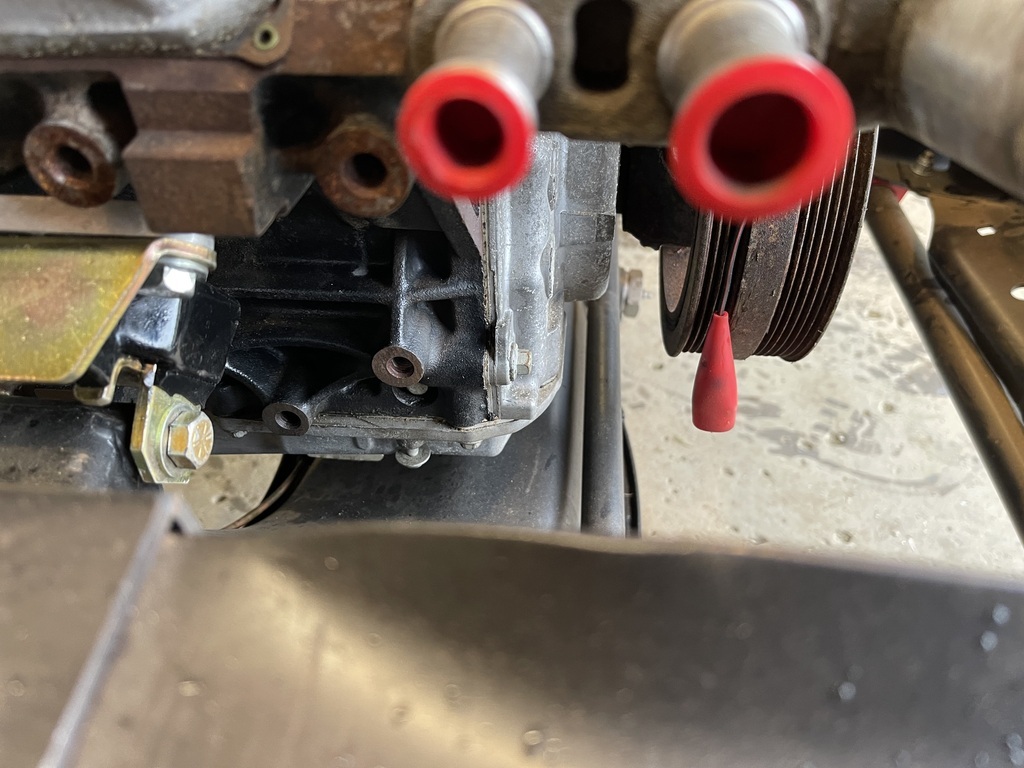

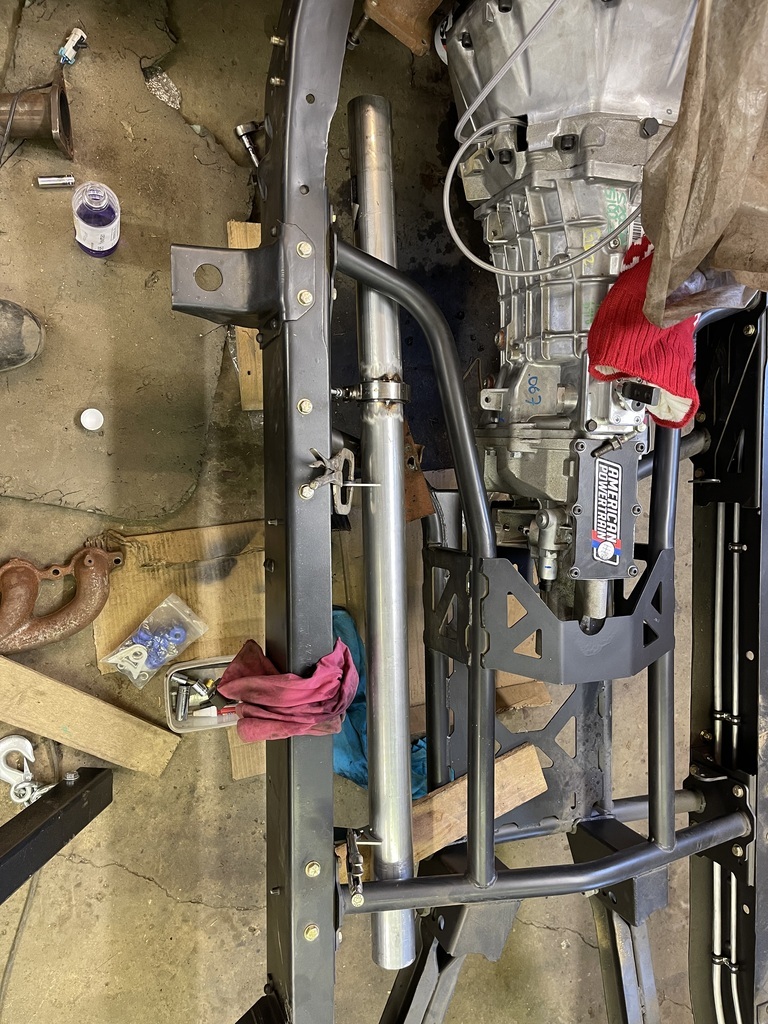

Whilst waiting for the indexing plate I did move the engine back as far as possible, the crank pulley is just in front of the crossmember now so pretty happy with that.

This did cause a slight issue further back as the gearbox extension was very very close to the strengthening in the boxing section.

.

Anyway, fast forward a week and these turned up courtesy of Mr. UPS.

As I headed out to the garage at 7am, in my head this meant that I would have the bell housing indexed and the gearbox in by lunch time, which meant I could then take Lady P out for a spot of brunch...

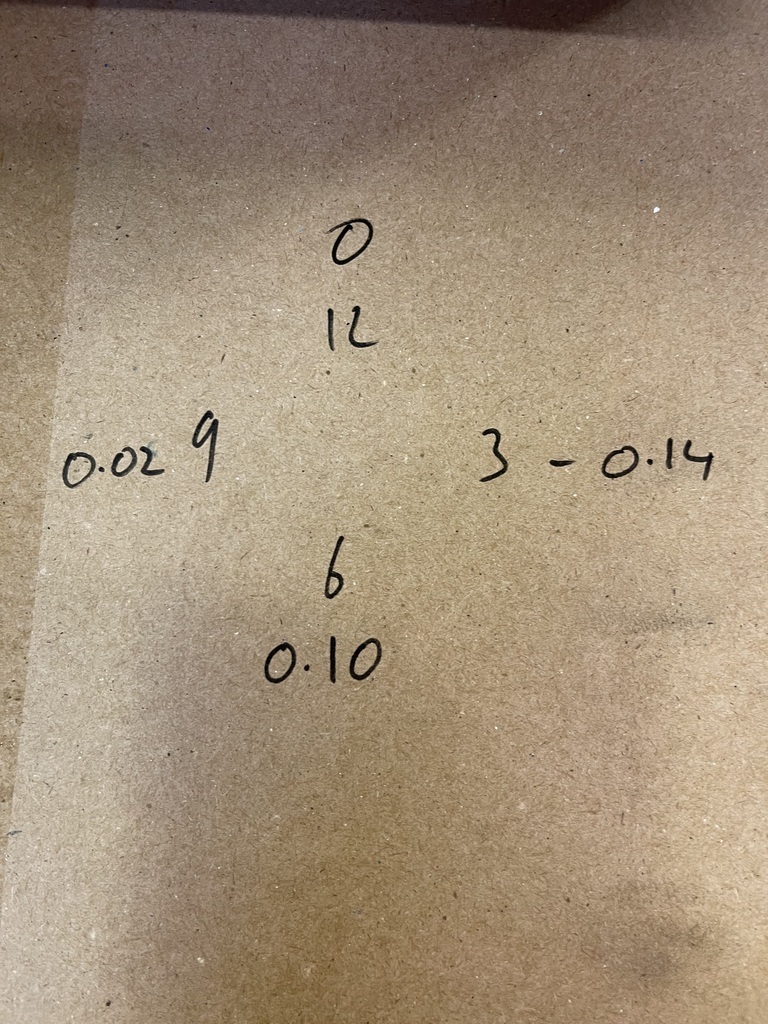

First things first, let's establish the high side of the dowel shall we.

Annnddd that is where my carefully laid plans went to complete rat poop....

There are very few things in life that I say I will never do again.

Watching The First Pokemon film, having Sepsis and now, added to that list indexing a cast aluminium bell housing.

This actually broke me both physically and mentally.

The problem was I couldn't get a constant reading for the concentricity. Every time I checked it the numbers were all over the place. I just couldn't replicate the numbers.

After HOURS of taking the bell housing on and off, adjusting the dowels, taking the readings - rinse and repeat- I knew that I was missing something. I went right back to basics, checking the run out of the flywheel, well within limits, and then checked the bell housing to make sure it was perpendicular to the block.

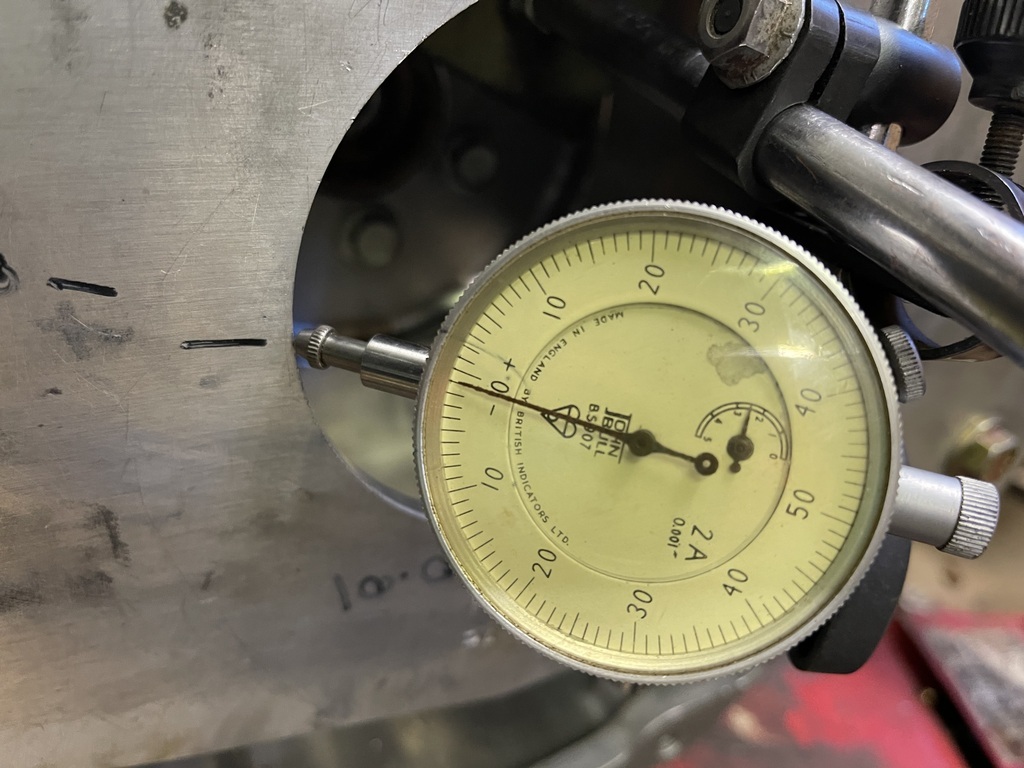

Bingo! I should have checked it at the beginning but didn't think about it (See above, above) The bottom of the bell housing was kicked out making it impossible to get a good reading. Finally traced the problem to the locating dowels on the index plate not being fully home and finally, FINALLy managed to get a constant reading. Even better was that is showed less than 0.02" run out.

Perfect.

I am now going to subject you to pictures of my success because this took me ALL DAY!

Good old John Bull

Next step was to Install this.

And this.

With these.

I could then measure the air gap before fitting this.

Before struggling for a further few hours to get this back in place.

By this time it was just after 10pm - Lady P had informed me in no uncertain terms that I was taking the P several hours previously - but I had to get this done for my own piece of mind. It is also the first time in my life that I have actually felt my age. Rolling around on a cold garage floor throwing gearboxes in is not a young mans game I realised.

Anyway. As I was already in the dog house I decided to get up early on Sunday morning to remove the gearbox again.

Why? I asked myself the same thing but I couldn't get over how apparently 'easily' the bell housing run out numbers were all suddenly 'in spec'. In fact I had been awake since 4.30 thinking about it so at 6am I was out in the cold undoing all my work.

By 8am it was all back in again, the numbers still checked out and I crept back into bed.

Question I ask myself is how did I manage to get it all out, check the numbers and get it back in again in two hours? Ah yes I remember...it was the threat of having a part of my anatomy, rather dear to me, removed with a rusty spoon if I dared set foot in the garage again this weekend.....

With martial life repaired to a degree I was given the green light to get a few hours in before dinner.

Right. Lets get that exhaust sorted out shall we....

Amongst my purchases this week were a few sticks of 2 1/2" exhaust tubing, 2 x V Band clamps 4 X 90 degree mandrill bends in addition to cabling, a 10 tonne press and all the required ends to make up the electrical circuit.

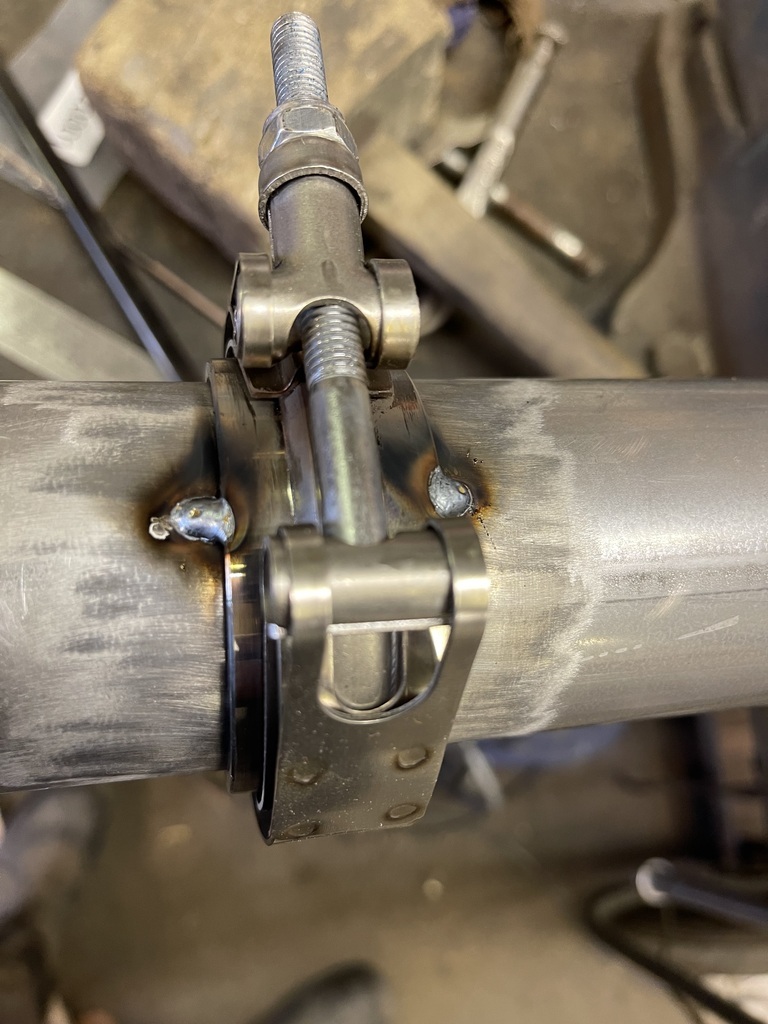

First things first, lets get a length of pipe cut down to size.

Tack the V Band in place.

And start to run things through the jungle gym.

According to Summit you can run a 3 1/2" system through the bars... I think they are being a bit over optimistic as the 2 1/2" doesn't leave a whole lot of room.

Sliced up the old down pipe and used my best metal glue technique to create this master piece.

BEHOLD!

Yup. Never going to be a welder...

Still have to replace the o2 bung but at least I am a 1/3rd of the way to getting an exhaust out the back.

Sorted of tempted to just straight pipe it but.....

Anyway, not wanting to sleep in the spare room I decided enough was enough and returned to inside for Sunday dinner and a bit of rubbish TV.

To answer the original question at the top of the page, the 9th April is not going to happen just because I don't have enough hours left to compete everything that needs to be done.

Loosing 2 weeks with the index plate, and then the dowels, just means I would have to be working ever night to even stand the remotest chance and, at that point, it becomes a chore rather than enjoyment.

Good news is that I am far enough forward that the end of April is looking like a safe bet, well until I forget to order the next thing I didn't think about!

So, until the next time, ONWARDS!!!

P.