All the little things that take time and effort to do and others will not no about or think of after the project build is complete but definitely make every thing work right and last for years to come.

I picked up some 36-4407 LMC Clear Parking Light Lenses with amber bulbs to rebuild the parking lights. The mounting nut plates for mounting the light assembly where broken replaced them with clip on nut plates. Sandblasted and painted the housing black to fit in with the black powder coated bumper. The stock shoulder screw (see insert pic of screw) would not hold the lens tight to the frame seal replaced them with #8-32 1-1/2 long stainless steel screws and locking nuts to prevent them from backing out.

You will notice an extra wire installed on the back of the light assembly, itís a grounding wire I installed. With all the powder coating and painting of parts the grounding of electrical parts can be compromised so Iíve found throughout the years that adding a ground wire keeps everything working good for years to come. Also on grounds I install that are exposed to the weather I seal them with Permatex 2 form a gasket sealant to prevent corrosion and failure. The sealant stays sticky for days and is like a tar substance preventing water and air corroding the connection. Note, would not recommend using a silicon/RTV type sealant to seal grounds the sealant has a small amount of acid base that has shown ground failure over time in the aircraft industry.

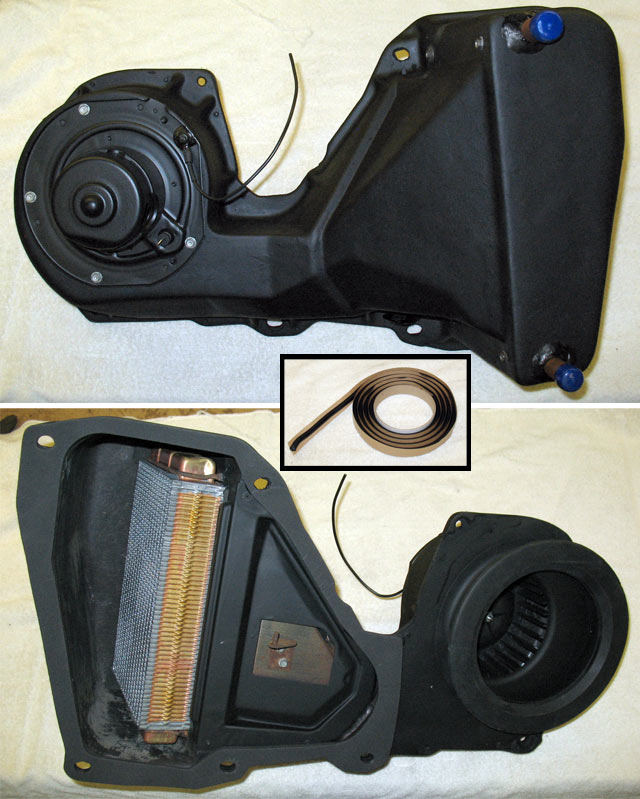

When I pulled the heater housing the heater core was leaking, the diverter valve was packed with pine needles and debris (probably the cause of the broken lever in the heater control that I replaced) and the fan motor did not sound very good when running.

Parts used in rebuild

32-2525 LMC Heater Core

36-0565 LMC Heater Seal Kit W/O AC

32-2420 LMC Blower Motor

32-2090 LMC Heater Fan

3M 1/4 inch glass Ribbon Sealer (see insert pic of bulk seal)

After disassembly and cleaning painted the housing with VHT Satin Black Epoxy Paint.

Decided to use the glass ribbon sealer instead of the factory clay like seal, it sits in the grove in the housing and holds the rubber seal in place good. Also used the ribbon seal to seal around the heater core hose connections. Now it can be set in storage ready for installation in the future.

Mounted the TCI transmission cooler and fabricated some aluminum tubing on the 32-2932 LMC Radiator 3 Row Cooler. Will have to cut two notches in the radiator support to clear the tubing.

I havenít finished the taillight concept at this time because Iím waiting for my friends to have some free time to help with the welding. Iím not the best at welding thin metal and like to use a copper backing plate to prevent burn thru and that requires a third hand I donít have at this time. But Iíve been keeping myself busy with other things that need to be done. Will keep you updated as the taillight concept progress, hopefully in the next post.