As it relates to metalshaping, planishing is a smoothing action. If you were to rough out a shape in a panel using a blocking hammer into a shot bag, it would add shape but the resulting finish would look about like a bag of walnuts. Planishing would be the process to smooth out those "walnuts" to a consistent finish. It would be accomplished using a planishing hammer, then English wheel, etc.

As it relates to welding in a patch.... As you weld, the heat will cause some expansion of the metal as it gets hot. This takes place at the weld and heat affected zone (HAZ-the metal surrounding the weld that has changed color) When it cools off, the molecular structure of the steel realigns such that it shrinks back down more so than what it was previously. Side note- whether you are welding sheet metal or 1" thick plate, any welding process will result in shrinking of the weld and HAZ.

Planishing in this case would be the process to add a bit of stretch to the area that has shrunk in order to restore the original shape of the panel. It is done directly on the weld itself, using a hammer and dolly. When you strike a hammer face into a dolly you will hear a PING. When you are planishing, it is hammer on one side, dolly on the other, and you want to hear that PING. You hear the ping, you are stretching. So when using the hammer and dolly to planish welds, it is advantageous to have a weld proud on both front and back side of the sheet metal, as these give you a "target" that is off the surface of the sheet metal for a more effective stretch of that one weld dot by its lonesome self. Dolly on one side, hammer on the other to strike the weld dot. I will typically grind down the individual weld tacks after planishing, as this get the weld proud out of the way for when you start overlapping, and it returns the metal thickness to what we set the welder up for.

Looking at your weld "dots", they have a divot on many of them. This is an outgassing that occurs as the puddle cools. I think you can remove some of that by using a hotter weld. Turn your heat up, add more wire feed speed if it tends to blow out, and shorten the trigger pull elapsed time.. So in essence, despite the heat being hotter from the machine's perspective, because the trigger is not pulled as long, the heat the panel sees is the same or less. (if we can get the operator adjusted as well ) I think you'll see that a hotter, shorter time-weld has the puddle sitting there boiling less, so the pin holes and divots SHOULD be less an issue. It should also give a flatter weld for less cleanup.

For your welds on a round patch, I would follow a similar pattern as you'd do with doing lug nuts on a wheel.. Where you said you turned down the heat due to blown holes, that may be due to having a gap in the panel. I would strongly suggest getting some scrap metal the same thickness as your roof skin, and practice on that, and not the truck, until the process and settings are dialed in.. and don't weld on a steel work bench. Your practice welds should be in free air, just as the panels on your truck are.

I've got a weld test coming up probably next week, a gap VS no-gap on two virtually identical panels so we can do a quantitative monitor of any difference in the results. Started with two panels stacked and added some low crown on the power hammer, then smoothed them out on the English wheel.

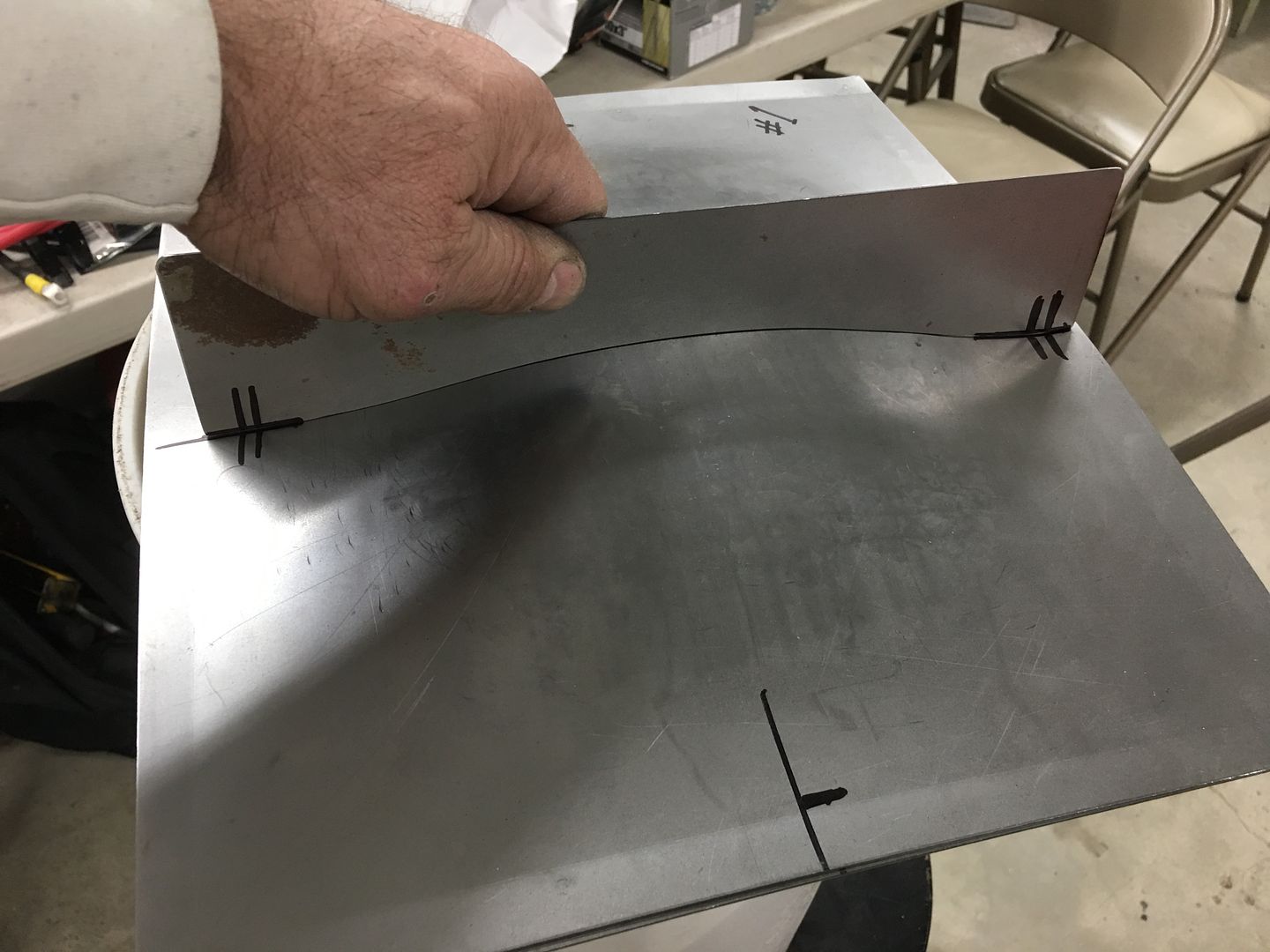

Then some profile templates were made so we can monitor any changes...

….one for each direction....

We'll cut equal sized "patches" out of each, leave a gap with one and the other will be tightly fitted. Both will be welded using MIG to keep that a constant. You may or may not be done when I get to that, but wanted to let you know we will be doing that. We should be doing some videos to better show the process...