2021 update!

I haven't been updating this thread like I had intended. The engine has been through a couple changes since my last update.

In June 2018, I ended up burning up the #2 piston because, like an idiot, I took internet advice and capped off my steam lines. That caused a hot steam pocket that burnt the edge of the stock cast piston. It went back to the machine shop.

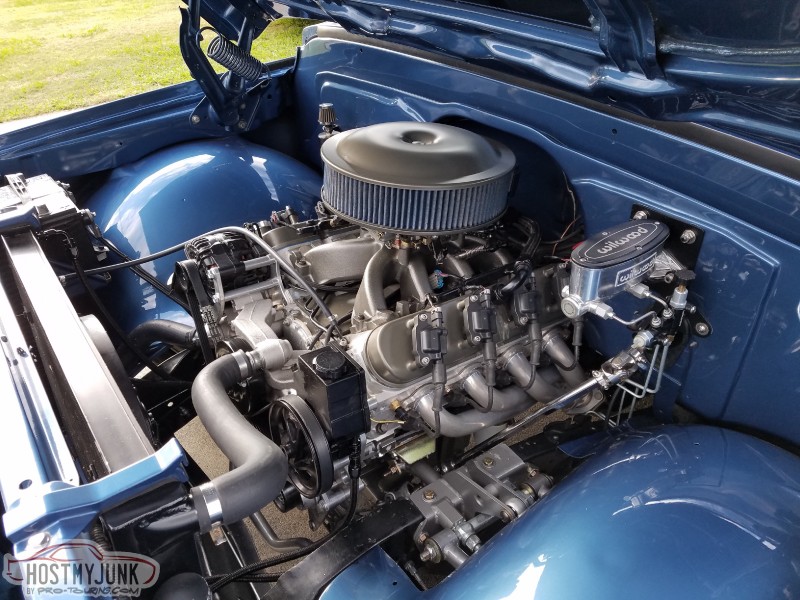

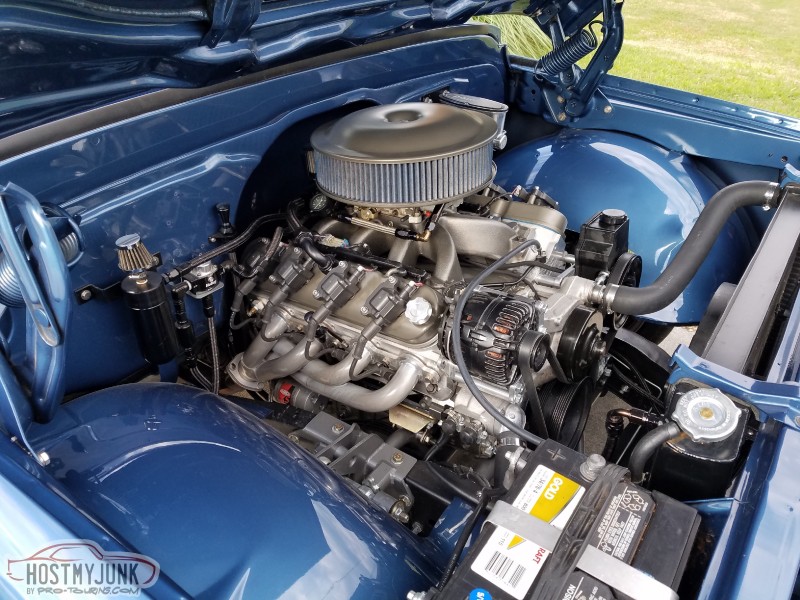

Version 2.1 received +.010 forged pistons, and we opted for a custom ground cam. The cam from before ran great, but it revved very quick, too quick actually. Most of the time on an autocross course, the engine would run out of rpms and be bouncing the rev limiter. The machine shop picked a cam that would rev slower, but still maintain good torque throughout the rpm curve.

This combo was good for 530hp/475tq. Now, that's not a huge difference from the previous numbers, but....it certainly felt much different! The engine made over 400 lb/ft from 2800 to 6000 rpm. It's pretty much always in optimal torque range.

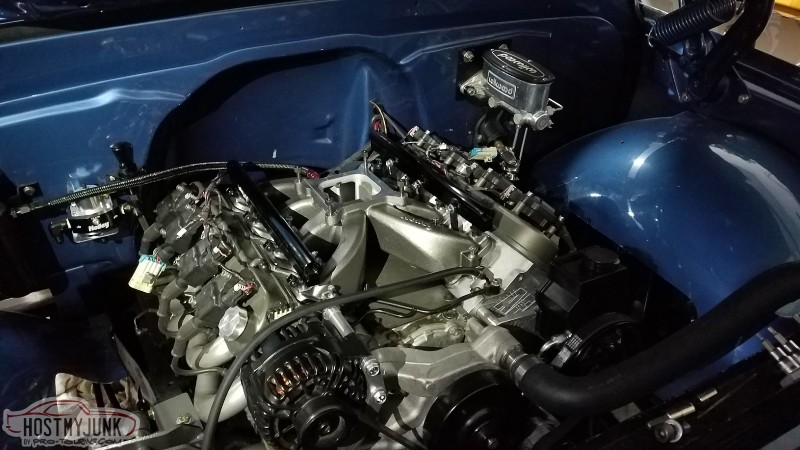

Version 2.2 was the swap from carburetor to EFI. Since I'm still running the 700R4, I had to use the 4150 style throttle body to utilize the TV cable bracket without any custom bracketry required for standard LS style EFI throttle bodies/intakes. It still uses the factory style 0411 PCM, Holley single plane intake/fuel rails/throttle body, and all hooked together with a PSI Conversions harness.

This setup worked very well until August 2020 when the engine called an audible at an event. That turned out to be a spun rod bearing!! The crank was damaged slightly and it got the oil pump. The crank is still useable, but the machine shop wasn't comfortable using an undersized crank for a "race" engine.

So...version 2.3 is now sporting a new forged crank, new forged rods, and still using the forged pistons from the last go-round, and a new Melling high pressure oil pump. The only valvetrain change was a new double roller timing chain since the previous chain was showing signs of excessive stretch. This combo should be much reliable seeing the constant high rpms.

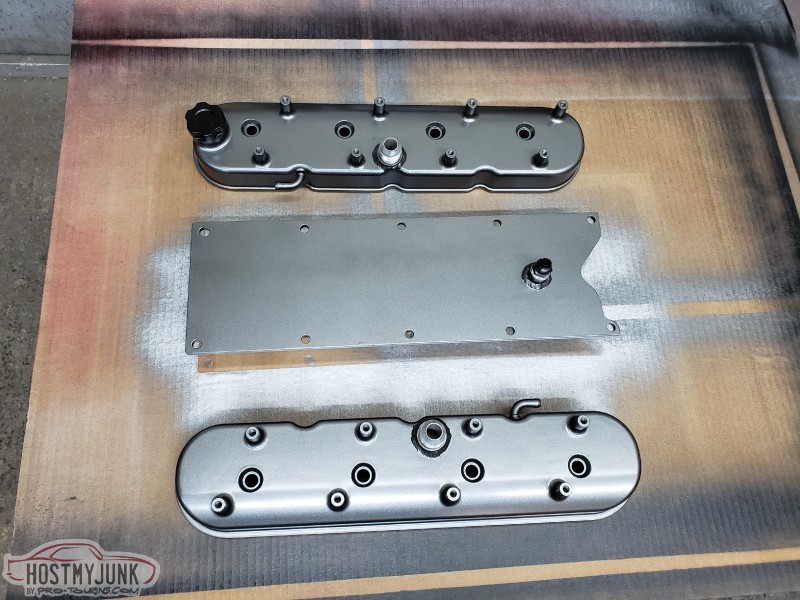

I decided a new paint combo was in order. I'm still using the VHT Cast Iron engine paint color, but covered the whole engine for a more uniform look. I've also painted the accessory brackets black. The engine isn't installed yet, so I'll get photos of it assembled later.