|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Registered User

Join Date: May 2013

Location: You're the only 10 I see

Posts: 367

|

Roof patch causing warp / oil canning

I am fixing an old CB antenna hole in my roof. The hole was in the center of the cab and I cut a 2" x 2" square to patch in with new metal.

About half way through tacking, I realized I had some major oil canning going on, and a hump on the sides and a valley on the top and bottom. The hump was about 1/8" up and the "valleys" also about 1/8" deep. I tacked fairly slow, 4 or 5 at a time and I don't think heat was the issue. These issues extended almost a foot around my patch in all directions. I decided to cut out what I had put in and everything settled back to where it needed to be and there is no warp. What did I do wrong with this patch, and how to I weld in this piece without the warp and oil canning?

__________________

1972 C20 |

|

|

|

|

|

#2 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: Roof patch causing warp / oil canning

Heat will do it...you need planishing

And I wouldnt do a square patch...round patch or radius the corners... Ps MP&C (Robert) will know for sure

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver Last edited by mongocanfly; 03-31-2021 at 10:35 PM. |

|

|

|

|

|

#3 | |

|

Registered User

Join Date: May 2013

Location: You're the only 10 I see

Posts: 367

|

Re: Roof patch causing warp / oil canning

Quote:

Can you elaborate why a square patch would be problematic for this, and how a circle would help?' I don't have any other tools for planishing, etc. I put a small radius in my previous square patch by rolling it over my rubber hammer to get it close to the crown of the roof. I'm not looking for perfection and expected a minor skim coat of filler, but not the warping I'm seeing..

__________________

1972 C20 |

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: Roof patch causing warp / oil canning

Near impossible to weld without warpage unless you can planish (stretch) the weld afterward in a low crown area like that. The weld tacks will shrink when they cool down, and that shrink pulls from all directions. So as the weld shrinks, about 6" or so out from the weld area, the panel remains cool and unaffected by the heat. The area between these two areas, caught between two differing forces (one shrinking, one staying the same) results in a buckling, a sinusoidal wave of distortion. To remove the wave adjacent to the weld, you stretch the weld to eliminate the pull. If ANYONE suggests using a shrinking disc, it is the incorrect process. You don't fix a shrink with more shrink. You may remove some of the wave but you will only be shrinking the center even more, resulting in a low area for more oil canning. Fix the cause, not the result.

When you cut around the perimeter of the welded area, the roof returned to normal as you "disconnected" the pull of the welds... More helpful hints: A 90* tight corner concentrates the shrinking effects on the inside of that corner for a noticeable pucker. A radius in corners helps to balance the shrinking effects on either side of the weld for an easier task of planishing out the shrinking deformity. For that small circle I would have used a round patch to fill the hole, not a square one. (food for thought) The tighter the patch (as close to zero gap as one can get) the better. A gap offers no resistance to the panel pulling closer together when the weld cools and shrinks, so any gaps will result in the outlying area pulling in more than with tight joints.. Where the crown of any panel is there to provide support and stability for the panel across its entire length, any disruption of that support risks oil canning. So for a low crown area like a roof skin, this means any additional shrinking/pulling in the center from gaps results in an even larger low area in the middle of the roof as that arc (cross section depiction) turns into more of a straight line. Which results in loss of that structural support that the crown gives, and an even greater likelihood of oil cans..

__________________

Robert Last edited by MP&C; 03-31-2021 at 10:55 PM. |

|

|

|

|

|

#5 | |

|

Registered User

Join Date: May 2013

Location: You're the only 10 I see

Posts: 367

|

Re: Roof patch causing warp / oil canning

Quote:

I canít tell for sure if you are saying this is an inevitable issue, or if the tips you proposed should avoid the issue.

__________________

1972 C20 |

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: Roof patch causing warp / oil canning

In the center of a low crown panel you are hard pressed to NOT have any distortion without planishing the welds.

It looks like your truck has the inner steel roof skin/headliner. This may work in your favor in providing some support if the shrinking occurs, but I think you will still have some distortion. Questions: When the antenna was installed, where did the cable come out? Did the antenna go through both layers? Does the cab have a cargo light that may provide access for a dolly in the form of a leaf spring?

__________________

Robert Last edited by MP&C; 03-31-2021 at 11:21 PM. |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: Roof patch causing warp / oil canning

Not that it helps in the center of a roof, but the following should help in understanding warpage.

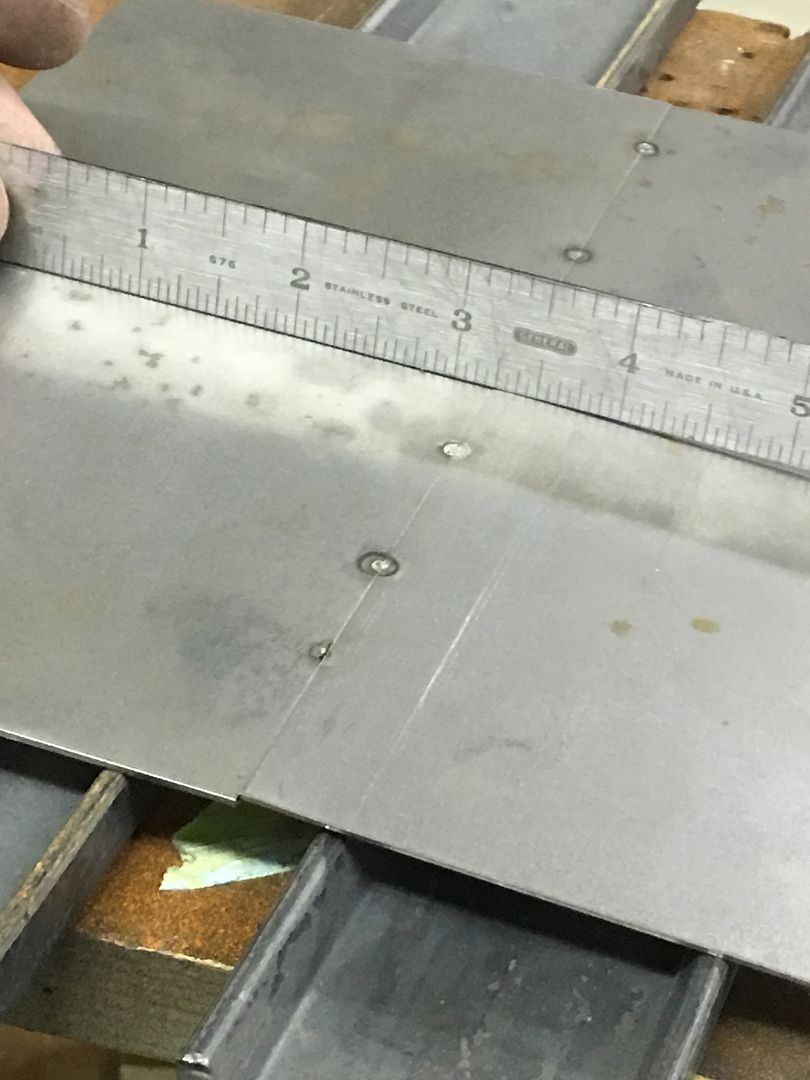

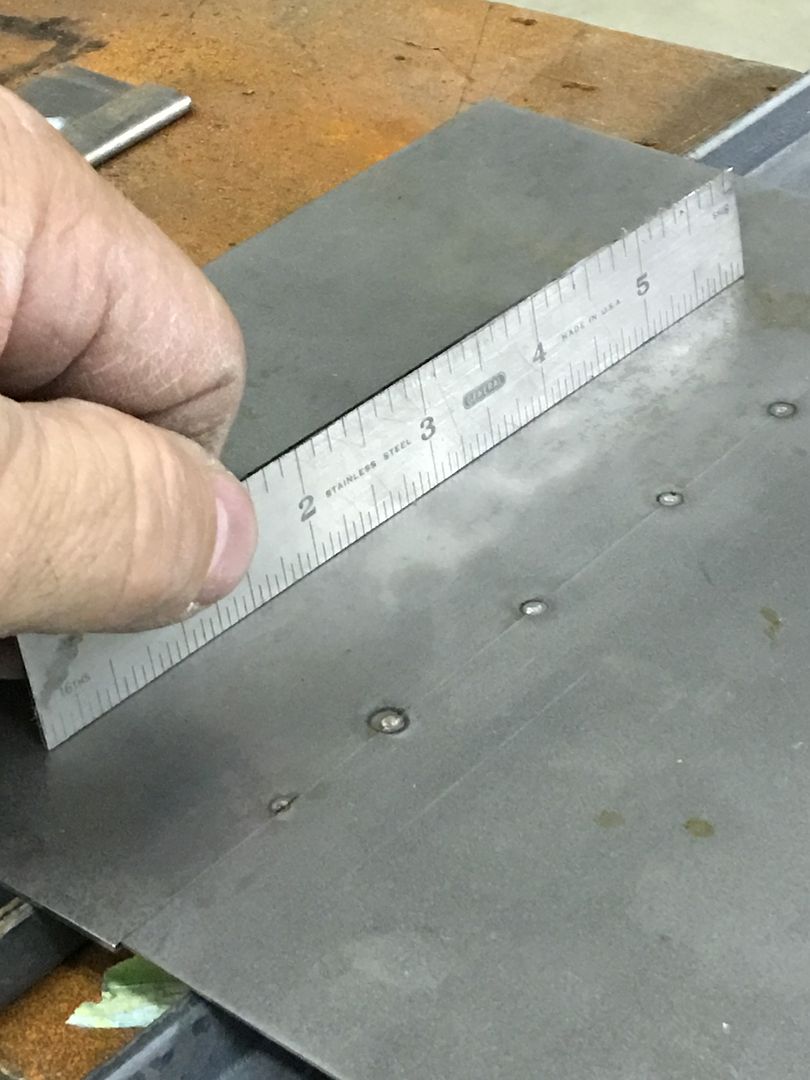

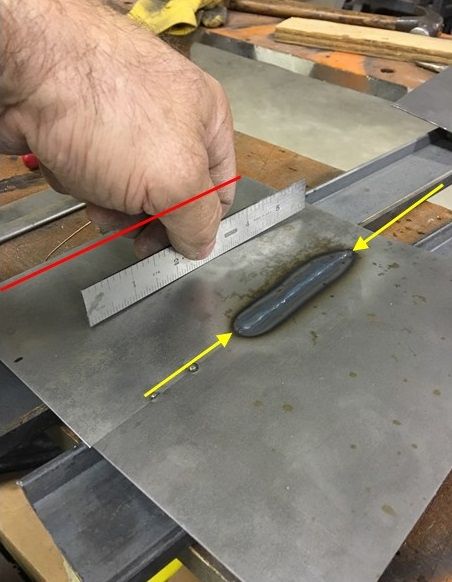

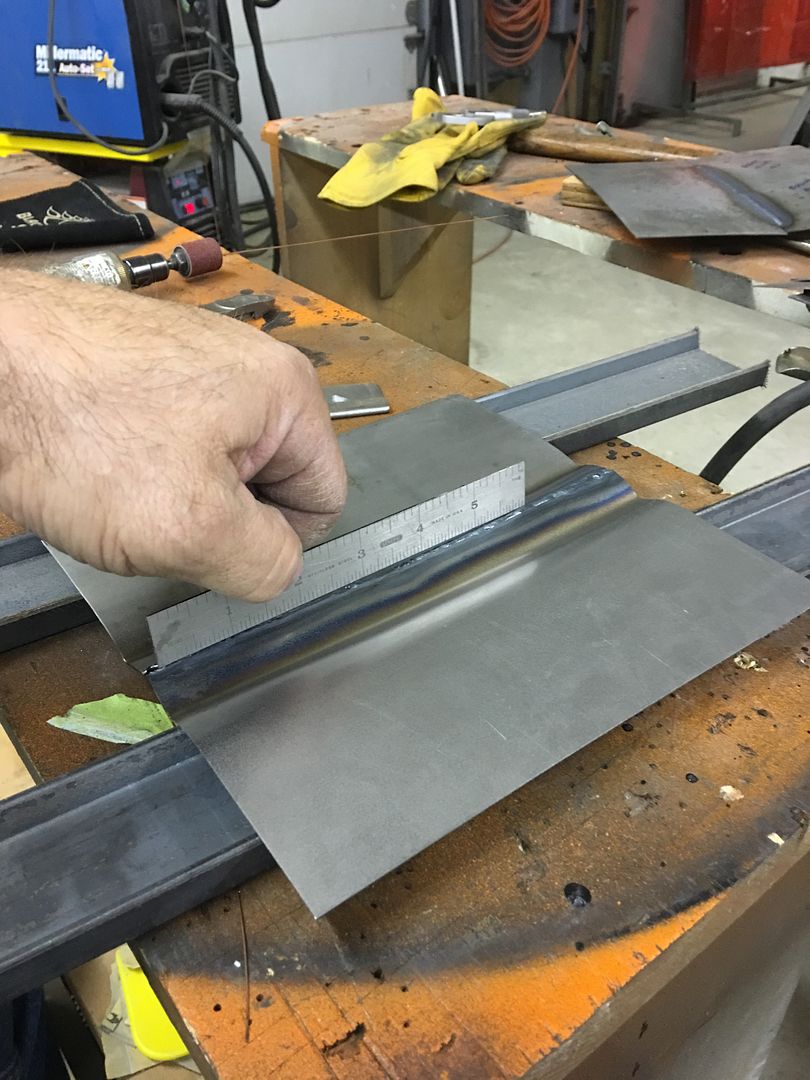

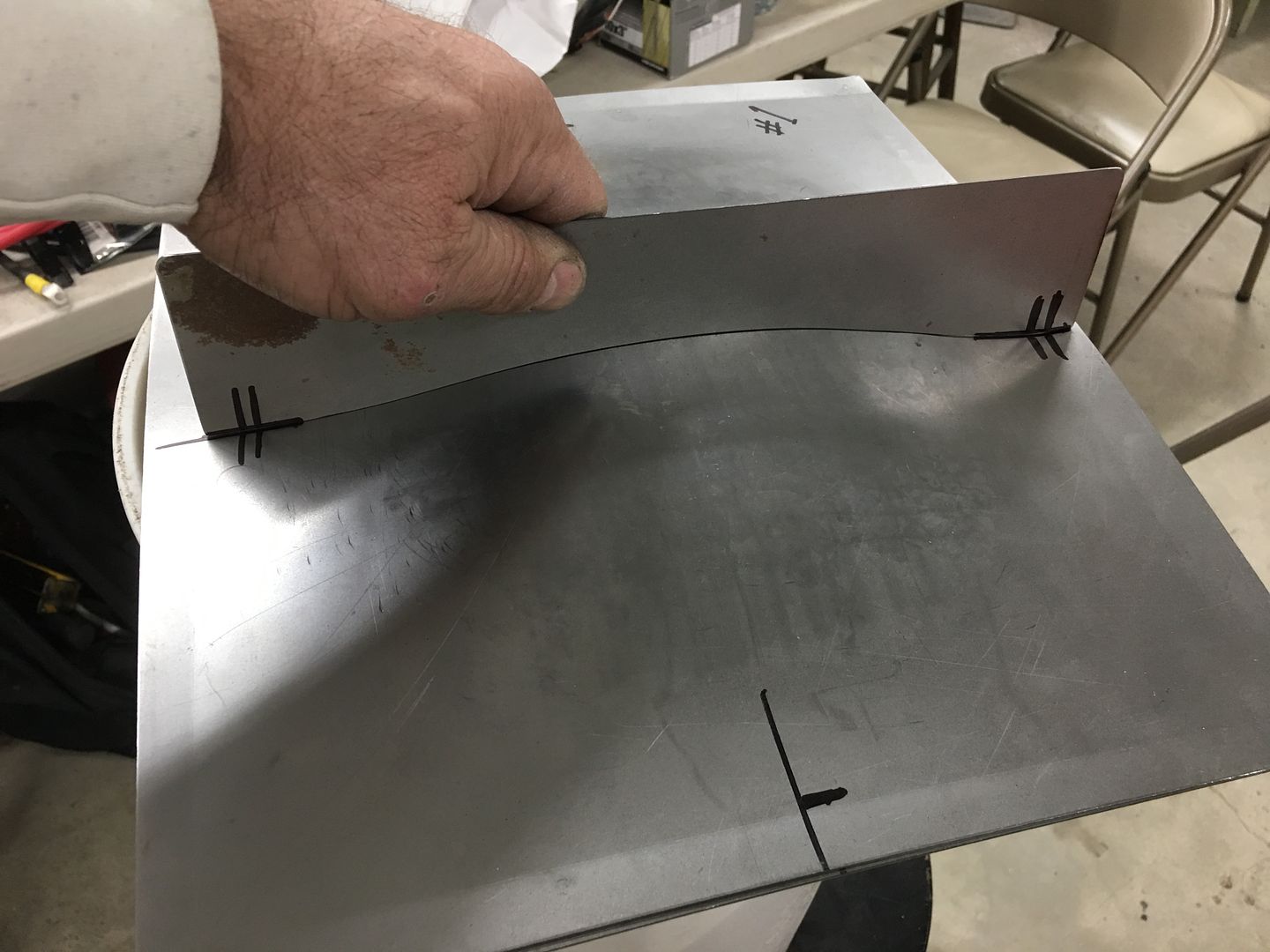

I hear people all the time suggesting to only use the bare minimum amount of a patch panel needed to repair the rust. I prefer to look at it another way, For example, most rocker panels have an outward crown that, if we cut out a patch for the front 1/3 only, we are left with a vertical seam. The shrinking that will indeed take place is going to give us a nice valley right at the vertical weld seam. So IMHO, it makes more sense to install a FULL rocker panel, where most are installed with spot (plug) welds at top and bottom flanges. Without using a vertical butt weld seam that you'd need for a partial patch, there is virtually no warpage at all in installing the full panel. For any other patches, (quarter panel, door corners, etc.), I worry less about using the least amount of patch possible, and more about putting a weld seam where you do have access to planishing. Additionally, a half height quarter patch puts your weld seam in the middle of a low crown area for a guaranteed warpfest. Using a taller quarter (even if not the OEM full height) puts the weld seam up higher where the profile usually has a higher crown, which helps to control the warping a bit better. So if given the choice here, I am using the tallest quarter available and putting the seam: 1) where I have access for planishing 2) in a higher crown area to help control warping 3) near body crease to help control warping (keeping enough distance for dolly placement). Other body panels would follow same 1-3 considerations in that same order. For trimming, I try to keep absolute tight joints and if using MIG, set the welder hotter, adjust wire feed faster if it tends to blow holes, and control heat with shorter length of time on the trigger pull. first and foremost, we need to insure full weld penetration, so some practice on scraps of same material thickness and clamped in mid air to simulate what is on the car. (metal welding table is a heat sink) To further explain gap vs no gap, anything welded is going to shrink when the weld cools. If you have a gap, the weld will pull the panels together as it cools, and each subsequent weld will pull it that much closer together. So if your panel had been trimmed correctly, now you have low areas being put in as the panel is moving. If the new patch is trimmed for a tight joint, then it will still shrink, but you will only need to planish to overcome weld shrinkage, and should not have panels moving together creating low areas. In essence, it will still need planishing as would a gapped joint, but with no gap it should remain more consistent where any planishing required is also consistent. With panels pulling together in a gapped situation, you will have differing planishing requirements based on how much the panel pulled in that particular area. Hope my rambling makes sense. I had done some test welds a few years back and I think the pictures taken will help out in understanding the weld location and shrinking. The tacks were done using the TIG and NO filler for minimal warpage. This also means we need absolutely tight joints... Here's the tacking process, and as said in video, amperage is set at 70. Based on 18 gauge thickness this should have been about 45, but as we also do with MIG "dot" welding, higher amperage and less elapsed time on trigger pull = flatter welds, less HAZ. https://www.youtube.com/watch?v=aTqQJoecqCw Note minimal weld size, minimal HAZ with the higher amperage, shorter burst...  Patches started out flat and for the most part remained so..   Adding a weld pass we are quick to see some distortion...   Examining this further, even though we have absolutely tight gaps for less instance of the panels pulling together, we still see distortion.. This is your typical weld shrinkage as the weld cools. Note in the next picture the panel is still fairly flat along the edges (red line), some shrinking at the weld (yellow arrows) and show a dramatic pucker between the two. Note that the weld has yet to be planished, so the weld shrinkage is pulling the metal alongside it together, the areas unaffected by heat remain largely unchanged (red line) and the area between the two are forming a bulge due to these differing forces. Here we address the problem, not the result. Planish out the weld to stretch it in length and the bulge will disappear. Don't make a habit of chasing the result, a shrinking disc on the bulge is not the correct resolution; if this were a crowned panel that action would be causing a severe low area.  Referring back to an earlier statement I made on weld location: ......let's try this same scenario using a crowned sample near a body crease so we can take advantage of all 3 choices...  Weld pass....    Here we can see how the weld location and panel features (crown, body crease) helped to control and limit any warping effects. The weld will still need planishing to restore the crown of the center bead, as no doubt it has pulled in slightly, but this is hands down a dramatic improvement over the flat "patches" we did the first time. This shows how these features in your body panels can help out in controlling weld distortion, so take advantage of these in weld location and leave the limiting of panel size as your absolute last consideration.

__________________

Robert Last edited by MP&C; 04-01-2021 at 06:23 AM. |

|

|

|

|

|

#8 |

|

Registered User

Join Date: May 2013

Location: You're the only 10 I see

Posts: 367

|

Re: Roof patch causing warp / oil canning

Thanks for the detailed response and the additional info Robert.

The antenna cable was fished through to drivers pillar and the hole did not go through the inner panel. My truck does not have a cargo light or any other way to get behind this patch. In my first attempt, I definitely had some gaps in my patch, and was blowing holes and turned my welder heat and wire speed down low, so it seems I had a major offense in at least two categories. I am not familiar with planishing techniques, is this something I will need to do if I canít get behind the patch? Once I get my circle patch cut, is there a recommendation for what order to tack in?

__________________

1972 C20 |

|

|

|

|

|

#9 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: Roof patch causing warp / oil canning

Square corners cause a stress point...round or radius corner patches eliminate that

I was thinking backwards above about shrinking..I was thinking you had a high spot out away from your patch...that needed shrunk .Robert set me right again..so I edited the above..

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver Last edited by mongocanfly; 03-31-2021 at 10:39 PM. |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: Roof patch causing warp / oil canning

As it relates to metalshaping, planishing is a smoothing action. If you were to rough out a shape in a panel using a blocking hammer into a shot bag, it would add shape but the resulting finish would look about like a bag of walnuts. Planishing would be the process to smooth out those "walnuts" to a consistent finish. It would be accomplished using a planishing hammer, then English wheel, etc.

As it relates to welding in a patch.... As you weld, the heat will cause some expansion of the metal as it gets hot. This takes place at the weld and heat affected zone (HAZ-the metal surrounding the weld that has changed color) When it cools off, the molecular structure of the steel realigns such that it shrinks back down more so than what it was previously. Side note- whether you are welding sheet metal or 1" thick plate, any welding process will result in shrinking of the weld and HAZ. Planishing in this case would be the process to add a bit of stretch to the area that has shrunk in order to restore the original shape of the panel. It is done directly on the weld itself, using a hammer and dolly. When you strike a hammer face into a dolly you will hear a PING. When you are planishing, it is hammer on one side, dolly on the other, and you want to hear that PING. You hear the ping, you are stretching. So when using the hammer and dolly to planish welds, it is advantageous to have a weld proud on both front and back side of the sheet metal, as these give you a "target" that is off the surface of the sheet metal for a more effective stretch of that one weld dot by its lonesome self. Dolly on one side, hammer on the other to strike the weld dot. I will typically grind down the individual weld tacks after planishing, as this get the weld proud out of the way for when you start overlapping, and it returns the metal thickness to what we set the welder up for. Looking at your weld "dots", they have a divot on many of them. This is an outgassing that occurs as the puddle cools. I think you can remove some of that by using a hotter weld. Turn your heat up, add more wire feed speed if it tends to blow out, and shorten the trigger pull elapsed time.. So in essence, despite the heat being hotter from the machine's perspective, because the trigger is not pulled as long, the heat the panel sees is the same or less. (if we can get the operator adjusted as well ) I think you'll see that a hotter, shorter time-weld has the puddle sitting there boiling less, so the pin holes and divots SHOULD be less an issue. It should also give a flatter weld for less cleanup. For your welds on a round patch, I would follow a similar pattern as you'd do with doing lug nuts on a wheel.. Where you said you turned down the heat due to blown holes, that may be due to having a gap in the panel. I would strongly suggest getting some scrap metal the same thickness as your roof skin, and practice on that, and not the truck, until the process and settings are dialed in.. and don't weld on a steel work bench. Your practice welds should be in free air, just as the panels on your truck are. I've got a weld test coming up probably next week, a gap VS no-gap on two virtually identical panels so we can do a quantitative monitor of any difference in the results. Started with two panels stacked and added some low crown on the power hammer, then smoothed them out on the English wheel.  Then some profile templates were made so we can monitor any changes...  Ö.one for each direction....     We'll cut equal sized "patches" out of each, leave a gap with one and the other will be tightly fitted. Both will be welded using MIG to keep that a constant. You may or may not be done when I get to that, but wanted to let you know we will be doing that. We should be doing some videos to better show the process...

__________________

Robert |

|

|

|

|

|

#11 | |

|

Registered User

Join Date: May 2013

Location: You're the only 10 I see

Posts: 367

|

Re: Roof patch causing warp / oil canning

Quote:

I am planning on tacking this in tomorrow, pending some more thought and review of the info above. If I understand correctly, I don't really have any real planish or "correction" options with this fix since I cant get behind it. My best bet is a good patch fit, slow welding, hotter welding to reduce the overall heat input? Should I be looking for / hammering down high spots as I tack, if they come up?? I am using a patch that is cut from leftover replacement floorpan material. The material is tri plus or key parts and just thick (if not thicker) than original. Ill probably do a small test as you mentioned with the heat higher than I am used to just to get comfortable.

__________________

1972 C20 |

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Dec 2015

Location: Beaver Falls, Pa

Posts: 168

|

Re: Roof patch causing warp / oil canning

For the situation you are in, I would use some metal adhesive (Fusor 208 would be my choice) to put the piece(s) in & limit your "effected" area. Over the years I've done several antenna/light holes in ex-police vehicles, ect. with no issues.

A round "backer" slipped in, half under the original skin & half to sit the patch on will allow for a better/flatter finish. You'll want to do it in two stages, put in the backer...let it dry, then install the filler piece. This way you can work through the hole to hold the backer in place until it dries I'm sure you have realized now that it would have been best a week ago to ask: "How would you guys go about filling this 1" round hole in this roof?", but hey...thats what makes it all a challenge. Lorne |

|

|

|

|

|

#13 | |

|

Registered User

Join Date: May 2013

Location: You're the only 10 I see

Posts: 367

|

Re: Roof patch causing warp / oil canning

Quote:

Definitely agree with this statement. However I have already done cab corners, rockers, floor patches, pillars, cab supports on this truck. This is my first rodeo obviously but I was looking at this hole as one of my last "easy" metal work tasks.... (wrong!).

__________________

1972 C20 |

|

|

|

|

|

|

#14 | |

|

Registered User

Join Date: Dec 2015

Location: Beaver Falls, Pa

Posts: 168

|

Re: Roof patch causing warp / oil canning

Quote:

I look at it this way, years ago someone made a mess by drilling the hole & then tightening down the antenna, raising up the area around it with the little bar/foot (Im guessing was the reason for you to cut the bigger hole?)...you didnt help matters by welding in the square cornered patch. Without cutting some inner cab away to properly work the weld area, the whole thing is going to be a compromise at best. The middle of a Roof (or Hood) is NOT the place to learn/practice...get something stuck in there to keep the water out & move on. You may see a "ghost line" around you patch under certain light being the sun heat will be beating on it some, but the outcome for the situation (no access, somewhat limited tools & knowledge) I feel its the best answer. Like I said earlier, Ive done several antenna holes (Roof & Trunks) just like what you had starting out without a problem. A couple I just tapped down a bit & glued a piece on top. NOT Robert-like, but for a 6 or 8 year old ex-police car...it works real well If its something you have interest in, I can go into detail of how to prep the parts, ect for the best results. My intentions are not to be-little your efforts or ability, just being a realist with the situation. Lorne |

|

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: Roof patch causing warp / oil canning

If you have any spare sheet steel around, I would practice the same patch on about a 12" x 12" piece to see how things react. make changes to see if one method works better than the other.

__________________

Robert |

|

|

|

|

|

#16 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: Roof patch causing warp / oil canning

They install body panels from with factory with adhesive..

Martinsr did a bunch of tests with panel bond with great results.. Is it right for what your doing? I dont know that..but somebody will.. Sounds like Lorne has done it any times..

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#17 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: Roof patch causing warp / oil canning

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jun 2013

Location: Somewhere

Posts: 3,100

|

Re: Roof patch causing warp / oil canning

MP&C is amazing and the detail he provides is nuts. He has a thread on a 55 Chevy that he and his minions show great work that everyone should look at from beginning to end.

Welding on a large low crown bit of metal w/ no ability to planish the welds is going to be a warping issue. Sorry. |

|

|

|

|

|

#19 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: Roof patch causing warp / oil canning

Robert...great explanation of gap vs no gap....

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: Feb 2014

Location: new smyrna beach fl / 29 palms cal

Posts: 1,727

|

Re: Roof patch causing warp / oil canning

I think the idea of using metal bond would be my choice. The idea of cutting a hole in the inner cab is only going to create more work, if the backer is kept to a minimum amount of overlap and you use slick-sand as your high build primer chances of having ghost lines would be slim to nun.

__________________

Hand made A/C vent manifolds for 64-66 trucks adapts any aftermarket A/C to OEM vent |

|

|

|

|

|

#21 |

|

Registered User

Join Date: May 2013

Location: You're the only 10 I see

Posts: 367

|

Re: Roof patch causing warp / oil canning

Thanks for the continued discussion. After some more research on the metal bond, it does seem this would be the simplest solution. This brings me to a few new questions as I plan to explore this direction further:

- Should I stick with my current ~2" square patch, or open the hole to be circular if using metal bond? - Do I need to leave a small gap around the perimeter of the patch for the material to bond the edges, or do I want it as tight as possible? - When placing a backer, do I want "space the backer" down toward the inner roof, so that there is a small gap between the backer and my patch for the bond material to fill? Or does it need to be completely flush? It seems if it is flush I will not get the patch completely flush with the roof line without pushing 100% of the bond material out of the joints. Clamping the backer in place first will also be a challenge, a tiny C clamp should do it but I am open to recommendations if anyone has tried a similar application. - Can anyone elaborate more on the ghost lines, and why these are a risk? I planned to sand/grind all the joints, skim coat with bondo, epoxy, high build, then paint. Im not understanding how this patch would be different after it is prepped like the rest of the cab. Thanks again everyone

__________________

1972 C20 |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Mar 2015

Location: Washington State

Posts: 1,651

|

Re: Roof patch causing warp / oil canning

Thanks for the detailed help here !!! MP&C you could almost write a book with your great detail and Pics! Great info.

__________________

John 3:16 - Saved me... God Bless |

|

|

|

|

|

#23 |

|

Registered User

Join Date: May 2013

Location: You're the only 10 I see

Posts: 367

|

Re: Roof patch causing warp / oil canning

I 2nd that! Much to be learned here and it is very cool people are willing to take the time to hand out free advice

__________________

1972 C20 |

|

|

|

|

|

#24 | |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: Roof patch causing warp / oil canning

Quote:

This video shows a reflection in the rear tailgate of a 54 wagon, the owner had done a nice job of restoring it, the car was neat as a pin. The only flaw was that he had used a stepped/flanged repair on the patch used on the lower tailgate skin. You can see the exact location of the seam, despite the filler used, and you can even pick out the screw holes that were plug welded closed. The other patches on the car were all butt welded with no discernable ghosting. I was given permission to take and show the video in hopes that others could learn from it and take prevention steps. https://www.youtube.com/watch?v=OGhFEfVqxb0 This occurs because you have two thicknesses of metal to one side of the weld, and a single thickness to the other side. Two thicknesses will take longer to heat up when exposed to sunlight (think car show) and longer to cool down that evening than the single thickness on the other side of the weld. This differing expansion and contraction rate will cause a ghost line right at the seam, showing exactly where the repair was made. So when I respond to various patch panel welding questions, this is also why I stress to grind welds on both front AND rear of the panel. We need the panel thickness consistent to help eliminate the cause of ghosting.

__________________

Robert Last edited by MP&C; 04-07-2021 at 08:25 AM. |

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: Feb 2014

Location: new smyrna beach fl / 29 palms cal

Posts: 1,727

|

Re: Roof patch causing warp / oil canning

I don’t think anyone is better at this than Robert and what he is telling you is 100% correct. In your situation and neither one of us having the skills that Robert has I still think metal bond is the way to go. I don’t think it matters whether it’s a round hole or a square hole just keep it to a minimum, if you use C clamps to hold your backer in place just don’t make them so tight you squeeze all of the adhesive out and then do the same with the patch it should equal out. The one thing I believe in 100% is to use a polyester high build like slick sand which has zero shrinkage as opposed to a 2K primer which will minimize if not completely stop any ghosting

__________________

Hand made A/C vent manifolds for 64-66 trucks adapts any aftermarket A/C to OEM vent |

|

|

|

|

| Bookmarks |

|

|