|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Let's rebuild a 350 (maybe), PT.1

Basically, what happened with this 350 is that cyl#4's exhaust valve somehow got in contact with the piston and actually broke off and imbeded itself in the piston; Before taking the head off, i noticed that the pushrod for #4's exhaust rocker was bent and the rocker was loose. This prompted me to take off the head to investigate further:

#4 piston:  Also, if it makes a difference, cyls 2 and 6 were full of oil and probably a mixture of oil and water:  What originally happened was that the engine started to run funny----the vacuum gauge swung wildly in pulse with the engine and the engine would stall out under 900 rpms. So, this prompted me to take the engine out and put in on a "test stand." The last time i tried to run the engine, i added more water to the radiator, but then water started to come out of the dipstick tube(there was apparently a small hole in the tube):  This, then prompted me to take the rocker covers off which led to one "gruesome" discovery after another with the exhaust valve etc. Water came out of the pan like so after the oil drained out:  The reason for the orangeish color is not due to rust----this is the new Dex-cool extended coolant. i'm trying to be practical here and decide to rebuild or get a new, reman(or even used) engine. So, please list all the possible reasons for the above AND in the order of likely hood. P.S. i took this head off 4 yrs ago to replace head gasket (which turned out to be unessesary due to mis-diagnosis of another problem) i don't remember if i used sealant on the head bolts, but i could possibly find out soon by looking at the books i used. Last edited by C-10 simplex; 09-26-2010 at 02:41 PM. |

|

|

|

|

|

#2 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

1) i looked at the head bolts and yes, all of them have some sealant on them; So, i feel that there is at least a 50% chance this was not the problem.

2) i also read that EGR intakes are prone to cracking. This engine has always had the factory iron egr quadrajet manifold that i love. a) Does water flow thru the manifold? i'm ASSuming it does? b) Any tips on how to check the manifold for cracks? |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: Let's rebuild a 350 (maybe), PT.1

A crack in the block or heads or manafold is possible, but i'm pretty convinced that if cyl's 2 and 6 had oil and water in them and that you previously removed the head for a "miss diagnised" problem then the problem IS a failed head gasket and intake manafold gasket or both, and also a possibility the head bolts didn't seal adding to the problem..

Did you re torque the head bolts after you put the head back on and it was run for a bit? did you recheck the intake manafold bolts again after it was run?? Did you put thread sealant on the intake manafold bolts that pass into the heads water jackets? if not tho's issues could cause a major leak which would fill the cylindars and crank case and also explane the vacume bouncing allover the place. As for why one valve failed its hard to say, if the timing was off i would think more of the valves would have contacted the pistons, or more pushrods would be bent so i'd rule that out. Is it possible you didn't have the pushrod properly adjusted or didn't have it properly in the lifter cup and rocker when you reinstalled it? its the only thing i can come up with along with the possibility bad lifter but a bad lifter wouldn't cause a broken valve. Yes water flows into the intake on a 350 (assuming its what you have) Now because you imbedded the valve head into the piston that piston is shot and needs to be replaced, that cannot be accomplished properly without a full rebuild with proper machining of the crank and block and now the heads by a machine shop followed by all new pistons, rings, valve job ect.... To be honest i think you should take the thing to a shop and let them rebuild it for you or buy a allready rebuilt engine because your "miss diagnised problem" and subsequent repair work is probably the root cause for the failure.. probably why there is a lack of response by other members here in 4 days. Good luck! EDIT: I just wanted to add that i'm not trying to be harsh with you or discourage you in any way cause we all have to learn sometime, but i think if you want to proceed with a rebuild you need some guideance from an experianced mechanic and not a book because there is just too much that a book won't cover.

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's Last edited by swamp rat; 10-01-2010 at 11:00 PM. |

|

|

|

|

|

#4 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

1) No, i did not re-torque any of the head bolts after running it for a while; i now read that you're supposed to do that.

Didn't check any of the manifold bolts either. i can't say with 100% certainty that i put sealant on the head bolts, BUT upon inspection, there appears to be some sort of sealant on all the bolts AND if the books said to use it (i used 3 books), then i very probably DID use sealant on all the bolts. a) engine "lasted" about 4000 miles after the head got put back on. 2) The "mis-diagnosis" was that white smoke was coming out of the right side exhaust pipe only----i have true duals. So, i thought it "must" be the right side head gasket. It turned out to be the vacuum modulator on the trans----this was discovered by sheer luck as the tube from the modulator to the intake fell off during a test drive and the smoking immediately stopped. i also noticed that the trans would not shift past 2nd gear.  On quadrajet manifolds the vac modulator tube plugs into the right side of the manifold, thus trans fluid was being burned by cyls on the right side of the engine etc. etc........ On quadrajet manifolds the vac modulator tube plugs into the right side of the manifold, thus trans fluid was being burned by cyls on the right side of the engine etc. etc........3) As far as the valve, do you think maybe cyl #4 filled up with water and the hydroliced taking the exhaust valve with it? i'm "pretty sure" i adjusted the rocker(s) right before putting the valve cover back on. a) why can't the piston simply be "cleaned up" and run as is? When i say "imbedded" i meant that when i took the head off i noticed that the head of the valve was stuck to the top of the cylinder---sort of like i coin on it's side. But i was able to remove it with my hands. You can probably see the vertical scuff mark in the pic----posted a better picture, previous one was incorrect. Last edited by C-10 simplex; 09-26-2010 at 02:41 PM. |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: Let's rebuild a 350 (maybe), PT.1

>>>The engine "lasted" about 4000 miles after the head got put back on.<<<

That still leads me to beleve the gaskets failed. >>> As far as the valve, do you think maybe cyl #4 filled up with water and the hydroliced taking the exhaust valve with it? i'm "pretty sure" i adjusted the rocker(s) right before putting the valve cover back on.<<< No, the cylinder cant hydraulic with the valve open and the valve had to be open in order for the piston to hit it and break it. i beleve the problem can be isolated to the install of the push rod, adjustment or rocker and lifter. Or the only other possibility i can come up with is the valve got stuck open momentarily and the piston hit it possibly cracking it at the stem, have you ever reved the engine so hard you floated the valves? >>>why can't the piston simply be "cleaned up" and run as is? When i say "imbedded" i meant that when i took the head off i noticed that the head of the valve was stuck to the top of the cylinder---sort of like i coin on it's side. But i was able to remove it with my hands. You can probably see the vertical scuff mark in the pic----posted a better picture, previous one was incorrect.<<< Its risky at best, If there is any indent or melting in the top of the piston i wouldn't do it, if it can be rubbed off with a little scotch brite and your fingers then its not bad. It was hard to tell with the picture posted, if the piston looks to have been compromised structurally i wouldn't run it, i don't think it will last and cause problems down the road.. That said maybe you can get someone to have a look at it for there opinion? Oh if you do take a little scotch brite to it you need to turn the engine over to move the piston to the top of the block surface and be really carfull not to get any if the stuff down the side of the piston [/QUOTE]

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's Last edited by swamp rat; 09-26-2010 at 03:22 PM. |

|

|

|

|

|

#6 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

The only time i revved the engine above 3500 was when i was doing some 1/4 testing and that was only once and it was about 6 months before the engine started acting funny.

a) i'm probably leaning towards improper installation/adjustment of #4's exhaust rocker/lifter also, but just as an outside possibility, i noticed that in the very first picture every valve spring top(not sure of the proper name) has oil on it EXCEPT for #4 exhaust. What's the possibility that the valve got starved of oil and got stuck in the open position thus causing the piston to strike it? 2) What i was trying to get at as far as "cleaning up" and trying to re-use the piston was i could see why now maybe this particular, #4 piston might need to be replaced, but why would all of the pistons need to be replaced/ crank and block machined/heads rebuilt etc. if it's just this one piston? |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: Let's rebuild a 350 (maybe), PT.1

I was thinking you may have wiped the oil off the valve spring cap when you were looking at it, my mistake for assuming. If it was like that then you definantly were not pumping oil from the lifter thru the push rod and out the rocker, now the question would be why? bad lifter? or a blockage in the supply to the lifter? blockage in the push rod? fualty rocker? lots of questions to answer.

If you replace one piston your going to have to replace the rings, in order to get the rings to break in and properly and seat you need to hone the cylinder, if you buy a ball hone and hone the one cylinder you run the risk of getting that grit all over the place inside the block, not a good practice. If you don't get all the grit cleaned out then the oil will flush the grit into the oil pan where it can and will get pulled thru your oil pump (good bye oil pressure)before it gets filtered, that is assuming you have a quality filter because there is one brand out there i wouldn't use for a paper weight, its name starts with an f, if the filter is fualty then all that grit is sent thru the engine siginificantly wearing all the bearings, journals ect... after a block is machined and honed its cleaned to remove all the grit. Now back to the lifter? How are you going to find out if its getting oil? by proper dissasembly and inspection of the block if its not getting oil then spending the money for a piston and bearing, rings new lifter and putting it back together is wasted time and money as its just gonna happen allover again. Also now your going to have one cylinder with higher compression than the rest if its done correctly. Lets not forget you will need to mic the cylindar/piston to figure out if the block has been bored over or if its stock before you order the thing... do you know what piston is in it now? is it stock or after market, can you match it?? speaking of, can you obtain a single rocker, push rod and lifter, rod bearing? all questions you need to ask. >>>i'm trying to be practical here and decide to rebuild or get a new, reman(or even used) engine.<<< This is one of your origional questions, Its up you what you do, what your thinking is a low buck compromise barnyard approach to the fix with a 50/50 or worse chance that it will not last, if ya do that then its your ball game. I'm not going to suggest anything more than if ya do one piston you should do them all and correctly by proper machining and cleaning (and chasing all the oil galleys to check for blockages ect. even if you can obtain one new piston just like the rest and all the rest of the parts i would still reccomend a full tear down and rebuild................Or, buy a Long Block..

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#8 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

No, i agree; Especially after the explaination why the one piston strategy really won't cut it, i am leaning towards a complete teardown to inspection to do it right. i was just hoping/wishing it would have been simpler.

But a complete teardown won't take too much longer if i work steady? |

|

|

|

|

|

#9 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

Just as an interesting twist, i started to take it apart and i can't get #4 exhaust lifter to move. Every other lifter on that side of the engine slid out no problem, but #4 exhaust won't budge.

i haven't tried turning the engine yet----don't have a stand. Will probably get a $45 harbour freight job asap. Will report back in a few days as i work double shifts every other day [yet make less than before(?)] |

|

|

|

|

|

#10 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

As an update i did get the $45 engine stand at harbor freight(see post in tools section) and took the other side head off. (NOTE: the pictures should re-size down in a few mins/hours)

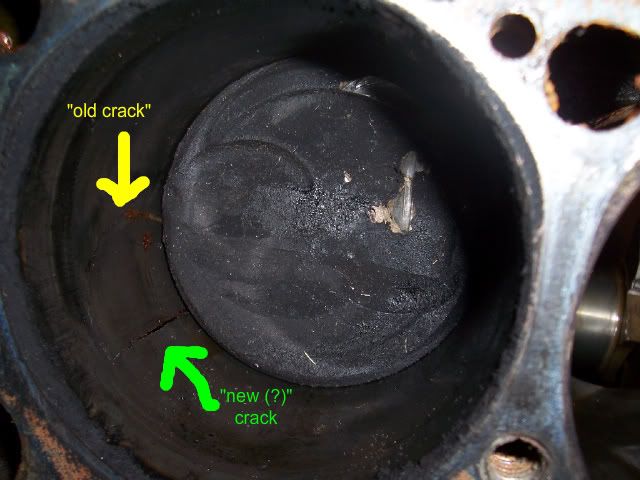

i was able to turn the engine when taking off the flexplate to crank bolts. This probably makes no difference because of my next discovery. This is what the bottom end looks like. 4 bolt mains. BTW this is/was a crate 350:  Here is cylinder #4; The piston clearly looks cracked and there is some issues at 3 O'clock and 5 O'clock in the first picture. Also the rod looks bent?:  different angles:

Last edited by C-10 simplex; 09-30-2010 at 11:29 PM. |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Apr 2000

Location: Delta,Pa

Posts: 14,950

|

Re: Let's rebuild a 350 (maybe), PT.1

It looks pretty clear that the engine is trash. It was definately hydrolocked to some extent. no matter how strong the internal are you cant compress liquid. Its hard to believe that valve bent the rod. At least it looks bent in the picture. A bad valve guide could have caused the valve to hang open and make contact with the piston.The cylinder wall is clearly cracked which explains your water in the oil. You need to find a new block

__________________

Owner of North Point Car Care in Dundalk Md. We specialize in custom exhaust on both modern and classic vehicles. We are a full service auto shop from classics to modern vehicles. Feel free to contact me with questions. I will give a 10% discount to any board member. |

|

|

|

|

|

#12 |

|

Badass

Join Date: Jan 2009

Location: lox. fl

Posts: 4,586

|

Re: Let's rebuild a 350 (maybe), PT.1

had the valve problem with one of my racing mowers. droped a valve and pushed into the piston. ended up welding the top of the piston up bumping up the compression

but yea dont do that

__________________

Think outside the box? -84c10 (1stcar)→My Build←  -00 Saturn 5spd drop a gear and disappear! 1/4:13:90

|

|

|

|

|

|

#13 | |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

Quote:

BTW, my pictures should re-size down in a few mins/hours. Is valve/valvetrain hangups common? i mean i've NEVER dropped a valve before. And i never really hammered this engine(except a few times). i'm just kind of disappointed for those 2 reasons. At the same token i bought this engine used with the truck, so i have no idea what the previous owner may have done with it. i'd say i only put about 10,000 miles on it before this happened. |

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Apr 2000

Location: Delta,Pa

Posts: 14,950

|

Re: Let's rebuild a 350 (maybe), PT.1

No its not terribly common. But it is possible that the valve guide is trashed and caused the valve to hang. Its hard to tell without seeing it in person.

__________________

Owner of North Point Car Care in Dundalk Md. We specialize in custom exhaust on both modern and classic vehicles. We are a full service auto shop from classics to modern vehicles. Feel free to contact me with questions. I will give a 10% discount to any board member. |

|

|

|

|

|

#15 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

i can take more pictures at virtually any angle if it helps.

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Jun 2006

Location: Indiana

Posts: 4,859

|

Re: Let's rebuild a 350 (maybe), PT.1

The rod is definitely bent. You said "The piston clearly looks cracked" but I only see the crack in the cylinder wall. That very bad! As well as the source of water in the crank case.

If the #4 lifter froze due to lack of oil, that would hold the valve open, piston hits valve, crank keeps pushing the rod up, but the piston-valve interference stops the piston, so the rod bends. The side load force cracks the cylinder wall. Dead in 10 seconds. Of course there is more wrong here, like why there was a lack of oiling.

__________________

'70 GMC C1500 LWB Power disc brakes. WooHoo! Posi 6 Lug Dana 60 |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: Let's rebuild a 350 (maybe), PT.1

Cableguy and Eraser5

I wonder about the valve head being able to bend the rod too really don't see any dings in the head ether so started to second guess. But put it this way, if you had a cracked cylendar first and were pumping water then the cylendar couldn't get hot enough for the valve head to stick to the piston correct? or could it have been stick there by compression alone? what else would have caused the valve to break? I beleve the lifter oil port is fed by a passage from the cam, i cant help but wonder if maybe a cam bearing was spun or if one was installed incorrectly causing the dry rocker and valve? still dosent explane the bent rod tho..  But any rate yea time to start hunting for another engine..

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's Last edited by swamp rat; 10-01-2010 at 12:46 AM. |

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Apr 2000

Location: Delta,Pa

Posts: 14,950

|

Re: Let's rebuild a 350 (maybe), PT.1

With the being multiple problems that are possibly unrelated its really hard to diagnose exactly what happened. Its possible that due to the water in the oil a lifter siezed in the bore. its hard to guess in which order things happened and to be honest it doesnt matter. The bottom line is that whole engine is nothing more than scrap. I wouldnt reuse anything other than maybe an intake from that pile. I can guarantee the valve didnt bend the rod. The rod is bent from the engine hydrolocking.

__________________

Owner of North Point Car Care in Dundalk Md. We specialize in custom exhaust on both modern and classic vehicles. We are a full service auto shop from classics to modern vehicles. Feel free to contact me with questions. I will give a 10% discount to any board member. Last edited by cableguy0; 10-01-2010 at 12:55 AM. |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jun 2006

Location: Indiana

Posts: 4,859

|

Re: Let's rebuild a 350 (maybe), PT.1

Which came first the chicken or the egg?

Did the oiling fail and cause the wreck or did the cylinder wall break and cause a hydraulic? We may never know. We do know that carnage happens and it sucks! Silver lining time. Now you can get a Gen II roller block and vortec heads. Or do that LS swap you know you want. I'm great at spending someone else's money!

__________________

'70 GMC C1500 LWB Power disc brakes. WooHoo! Posi 6 Lug Dana 60 |

|

|

|

|

|

#20 | |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

1) i don't know if it helps, but when i first took the valve cover to inspect (engine was still in test stand), i first saw the #4 exhaust rocker loose AND then noticed the exhaust pushrod was bent.

i then went to AdvanceAuto and got another pushrod and then tried to run the engine again(stupid, i know....) and it maybe ran for a second or two and then i tried to run it again and then i could not get it to turn over---in other words crank would not turn; i had thought then that the battery had run down. i then had to go to work. So, about 8 hrs or so later i try running it again but notice that the radiator is low on water. So before even trying to start it, i add more water and that's when water started coming out the dipstick tube, pan etc. Quote:

2) Actually, i am leaning towards rollers. Example: http://www.jegs.com/i/GM-Performance...oductId=753961 a) As far as LS, i would consider it if i could find a shop that could install one for me quickly AND diagnoise and repair stuff quickly and accurately. OR find a complete turnkey system. All that being unlikely, i think i'll stick with gen 1+2 small blocks. b) i think i might even take a chance on another, but new this time crate 350. i am a little disapointed at the situation because this seems to indicate poor quality----maybe. Or maybe it was just bad luck for me. But again, i have no idea what the previous owner did with the engine and how it was driven----i could tell he takes good care of his equipment, but his daughter, son in law and son do not appear to be responsible folks. And i can tell they all drove it. As comparison, the spare 305 that sat in my garage for about 7 yrs, fired right up after pre-oiling and is now in the truck. This engine replaced the sick 350 we are talking about. The 305 is from a 78 malibu and runs like a top. That's 32 years, no rebuilds as far as i know. And the 350 based on paperwork is only from 96. Actually, before making my next move, i have a few more questions concerning the valve train and maybe what caused all this...... i am getting a little better with engines. Last edited by C-10 simplex; 10-01-2010 at 02:26 PM. |

|

|

|

|

|

|

#21 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

Next question, do the rod journals pretty much have to be at BDC (rod journal position, not piston position) to be able to take the pistons/rods out?

As you might be able to see in some of the above pics, cyls #5 and #6's rod journals were pretty much at bdc or 6'0clock if you were looking at the engine right-side-up. And they came out pretty easy. As you can also see in the pics, or can use your imagination, #3+#4's rod journal is at TDC; i was able to get #4 and #3's rod cap bolts off, but i could not quite get #3 out. i got the piston about even with the deck, then it stopped---it may have been coming in contact with the bottom of the cylinder. #4 will move about 1/8" then it stops. i'm thinking this is due to the cracks in the cylinder wall. Also, because of those cracks, i'm thinking it's difficult to turn the crank. Last edited by C-10 simplex; 10-11-2010 at 03:47 AM. |

|

|

|

|

|

#22 | |

|

Registered User

Join Date: Jan 2003

Location: Safford,AZ

Posts: 3,613

|

Re: Let's rebuild a 350 (maybe), PT.1

Quote:

A L31 would have the vortec heads and roller cam for not much more- http://paceperformance.com/index.asp...&ProdID=225981 or a L31 short block- http://sdparts.com/details/gm-factor...parts/12556121 cam- http://cgi.ebay.com/ebaymotors/350-5...Q5fAccessories |

|

|

|

|

|

|

#23 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

OK, so parts #12530283 and 12530282 are the other "truck" engines that are roller and the 12568758 is flat lifter. Thanks for the clarification.

The roller engines don't seem to be able to run a mechanical pump which is not a big deal in my opinion. The rollers seem to make almost the same power as the base crate 350, but with higher compression and rollers, better mpg? |

|

|

|

|

|

#24 |

|

Account Suspended

Join Date: Dec 2008

Location: indisclosed

Posts: 1,515

|

Re: Let's rebuild a 350 (maybe), PT.1

Anyways, on with the dismantling:

What would you do? The crank will turn---with effort and i was able to get #3 out with no problems after getting 3+4's rod journal to BDC. However, #4 won't move even after pounding with a hammer and pipe with rubber on the end of it: Also, there might be some new cracking caused by moving that #4 piston up and down in the bore:  Would it be better to take this piston out from the bottom or top? There hasn't been any ridges on the cylinders of the pistons i've taken out so far and #4 doesn't appear to have one either. P.S. When turning the crank, #4's exhaust lifter, which is still stuck in there did not appear to move. Just thought i would throw that in there for anyone who is still curious; The timing chain is still connected. |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Sep 2010

Location: Richmond, Va

Posts: 573

|

Re: Let's rebuild a 350 (maybe), PT.1

time for a long block

|

|

|

|

|

| Bookmarks |

|

|