|

|

|

#1 |

|

i've created a monster

Join Date: Jun 2005

Location: Plain City, Ohio

Posts: 70

|

ok, i know the 2bolt is stronger due to the bolts on a 4bolt being too close, but what i have never heard is about how much hp a 4bolt can handle, and is there anything that can be done to lessen the likelihood of this happening. i have a 4bolt main block, and i am going to be dunking a lot of money into this build, i just don't want to get it together, and have the bottom end break apart. any input would be appreciated.

__________________

69 GMC C20, with an 81 CHEVY K20 drivetrain |

|

|

|

|

|

#2 |

|

Mean Green

Join Date: Sep 2007

Location: Portland, OR

Posts: 522

|

Re: 400 4bolt main

I have built a hand full of sbc 400's

I have always taken 2 bolt and turned it into a splayed 4 bolt. But with the cost of machine work and caps your only a couple of hundred away from a after market block. A 4 bolt, blocked filled to bottom of freeze plugs or even more and deck plugs. With Hi nickle good cast that's been sonic tested and checked out should handle 600-700 HP Counting on you have a real good machinist. But if you want to build a bionic motor, Aftermarket is the way to go. That's just my opinion. |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Oct 2005

Location: Orygun

Posts: 169

|

Re: 400 4bolt main

+1 what 68 kid sez

__________________

http://www.cardomain.com/id/Schralper |

|

|

|

|

|

#4 |

|

Registered Truck Offender

Join Date: May 2008

Location: hells training ground (aka Ariz)

Posts: 3,118

|

Re: 400 4bolt main

x2

If your putting a couple or three thousand in a rotating assembly, a couple thousand in heads, thousand in cam/lifters,,,, and spending a thousand + on the machine work to bandiad a casting that was never intended for anyhtng over 350HP....... just doesn't make sense. The Dart SHP block is an outstanding value. A couple of issue (like the 350 mains, and strokes over 3.875 take a BUNCH of clearancing) but all in all I would not spend 3, 4 or 5 thousand on a motor without investing $1300 in the insurance of a solid platform of a good block. If you are looking to scrimp and save on the motor build,, consider it 'disposable' if built in a stock GM casting. Then it won't bother you if it all comes unrevelled

__________________

Still playin with trucks, even at my age! When you're dead, it's only a problem for the people around you, because you don't know you're dead. .....It's kinda the same when your STUPID. I just did my taxes and reviewed my SS statement. Thanks to the current administration it looks like I will only have to work till noon on the day of my funeral. |

|

|

|

|

|

#5 |

|

i've created a monster

Join Date: Jun 2005

Location: Plain City, Ohio

Posts: 70

|

Re: 400 4bolt main

ya, that's kinda what i was afraid of. i'm already scraping the barrel for the heads and rotating assembly that i'll be getting for it, and while i don't want it flying apart, i gotta admit, i don't have 2k to drop for a sportsman block. as far as machining goes, i work at a custom steel fabrication/machine shop. we have a bore machine, line bore, milling machine, and lathe. we are not set up to do larger engine work, but we have what it takes to get it done. my target horsepower is around 500, but i guess i'll have to make a decision on what to do here. also, forgive my ignorance, but this is my first performance build. what exactly is "filling a block to bottom of frost plugs", and "deck plugs"? i assume filling is pretty much what it sounds like, filling the bottom of the water jackets to provide additional strength for the bottom end? like i said, newbie at high performance builds, and just want to get it right the first time. also, just fyi, this is not going to be an engine that gets the crap run out of it. i do take care of my equipment, and i don't abuse it. lol, costs too much when things break.

__________________

69 GMC C20, with an 81 CHEVY K20 drivetrain |

|

|

|

|

|

#6 |

|

Mean Green

Join Date: Sep 2007

Location: Portland, OR

Posts: 522

|

Re: 400 4bolt main

Block filling is what you thought it was. Morroso sells a block hardener and some others also.

If you pull off heads you will see 2 big 3/4" holes next to the cylinder bores. Pipe tap them. Then locate pipe plugs that are solid not hallow. When you Deck the block you machine off whats left over. When you bore I also recommend a torque plate. FYI if block filling its recommended to run synthetic. It handles heat better. With no water at the bottom of block the oil doesn't get the cooling I believe. |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Oct 2005

Location: Orygun

Posts: 169

|

Re: 400 4bolt main

500hp outta a 400 isn't a problem, w/ a stock block.

200cc or bigger heads/ roller cam (like CompCam XR276HR or bigger) though flat tappet (like 234@.050) can work just smaller powerband/ 10:1 comp or 11:1 w/ AL heads.

__________________

http://www.cardomain.com/id/Schralper |

|

|

|

|

|

#8 |

|

i've created a monster

Join Date: Jun 2005

Location: Plain City, Ohio

Posts: 70

|

Re: 400 4bolt main

yup, that's exactly what i've been planning for schralper. but now i have located a 2bolt virgin block for $175. comes with a crank and pistons, etc. like that matters, though... but anyway, i kinda figure i might as well get it, so i have a stronger bottom end with the splayed caps. quick thoughts? prolly go get it friday if it's still available. oh, and casting number is 3951509 for the 2bolt

__________________

69 GMC C20, with an 81 CHEVY K20 drivetrain |

|

|

|

|

|

#9 |

|

i've created a monster

Join Date: Jun 2005

Location: Plain City, Ohio

Posts: 70

|

Re: 400 4bolt main

well, i decided screw it, i went and got the 2bolt block to be safe. thanx u guys for the advice, i want a bulletproof bottom end, and this should do the trick.

__________________

69 GMC C20, with an 81 CHEVY K20 drivetrain |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Feb 2001

Location: Wetumpka, Al, U.S.

Posts: 8,891

|

Re: 400 4bolt main

I would only use an aftermarket 400 block unless its gonna be real stock.

__________________

Kevin Special Thanks to All who have helped on the TRUCK! My Pass Time Show http://s129.photobucket.com/albums/p...Chapter1-0.mp4 So Far my best Times are: Motor only: 6.44 1/8 @ 104.13 10.39 1/4 @ 125.83 Nitrous Times: 5.785 1/8 @ 118.65 with a 1.336 60ft 9.168 1/4 @ 142.58 with a 250 shot dead out of the hole! |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jun 2006

Location: Jackson, Mo.

Posts: 607

|

Re: 400 4bolt main

Just my 2 cents worth: a factory studded 2-bolt 400 block can handle your goals without any trouble. As a matter of fact, the factory crank can handle 500 hp, also. Some people might disagree with this, but I've seen plenty of guys running this equipment at these power levels ( and some higher ) and I've built a few of my own that made 500-550 or so with factory blocks and cranks.

I don't know what displacement you're looking at building, but if it's a 406, I wouldn't hesitate to use the block and the crank. The biggest issue to address will be QUALITY machine work. Make sure whoever you deal with has experience with high-output engines and is familiar with what you're planning on doing. One thing that will help the crank live in something like this is to use a set of strong, but light, rods and pistons. Any weight you can keep out of the rotating assy. will keep everything happier inside the engine. Now, with all of this being said, if your budget will allow an aftermarket block and rotating assy., then, by all means, build it as big and as bad as you can afford to. It's never a bad idea to use parts like these, if your budget can stand it. Good luck with whatever choice you make!

__________________

Chris 1966 Chevy C10 LWB, 434 sbc, TH350, 12-bolt, factory suspension, pump gas 7.02 @ 95.8, 1.45 60' 1965 Chevy C10 LWB, 355 sbc, TH350, daily driver |

|

|

|

|

|

#12 | |

|

Registered Truck Offender

Join Date: May 2008

Location: hells training ground (aka Ariz)

Posts: 3,118

|

Re: 400 4bolt main

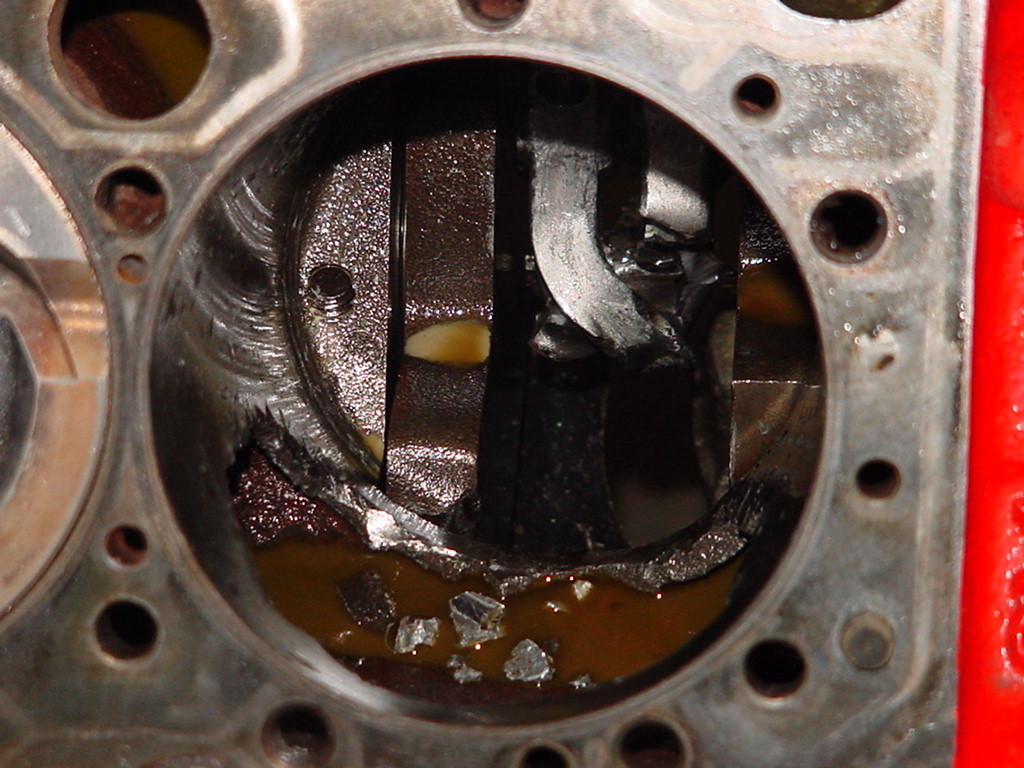

I almost hate to do this but..... This motor was put together with decent components (except for them frickin KB hypereutectics) ,, in a 509 2bolt block @ +.040 for 409, studded top and bottom, cement filled to the frost plug holes, just at $1000 in machine work in the BLOCK, (sonic checked, line bored with new steel caps, decked, stress plate honed) Scat I-beam rods with the good bolts, Cast crank (which is the ONLY thing in this motor not destroyed BTW), AFR cnc 210's with a TON of work in them, (cause that's what he had) Lunati solid roller (264/276, .625 lift)

Figure it was making an honest 560HP propelling a 3200 pound Nova to 10.20's on a 9" tire, footbrakling and shifting a TH350 at 6700 (we wanted to save the motor so no hard revving LOL) I refer you to the Roger Rule #1( Quote:

BTW, that's what we saw when we pulled the head. That KB hipereutectec turned back to the sand from whence it came. We didn't remove it,, it was dust in the pan. Oh yes, and the big reason for that pic. See the big water passage hole in the deck above and between the bores. That's the holes to be pluged with pipe plugs and then milled flush. We had 2 sleeves in this block due to microscopic spiderweb cracks radiating from the head bolt holes to the edge of the bores. (a common thing in 400 small blocks, HAVE your block checked before you spend $0.02 on it). Anyways, the plugs add stress to the deck and we didn't want to add stress to a deck that already showed some issues is why these wern't plugged and milled.

__________________

Still playin with trucks, even at my age! When you're dead, it's only a problem for the people around you, because you don't know you're dead. .....It's kinda the same when your STUPID. I just did my taxes and reviewed my SS statement. Thanks to the current administration it looks like I will only have to work till noon on the day of my funeral. Last edited by Marv D; 08-15-2009 at 12:09 AM. Reason: add info |

|

|

|

|

|

|

#13 |

|

i've created a monster

Join Date: Jun 2005

Location: Plain City, Ohio

Posts: 70

|

Re: 400 4bolt main

haha, i like lessons that i didn't have to learn the hard way. duly noted: stay away from kb hypereutectic pistons, and have block sonic tested. now, one last question, u've explained which jacket ports to plug and mill, but what is the exact purpose there? is it a matter of helping keep the deck from flexing?

__________________

69 GMC C20, with an 81 CHEVY K20 drivetrain |

|

|

|

|

| Bookmarks |

|

|