|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Registered User

Join Date: Nov 2013

Location: Northglenn, Colorado

Posts: 186

|

Re: Rust Therapy - 62 C-10

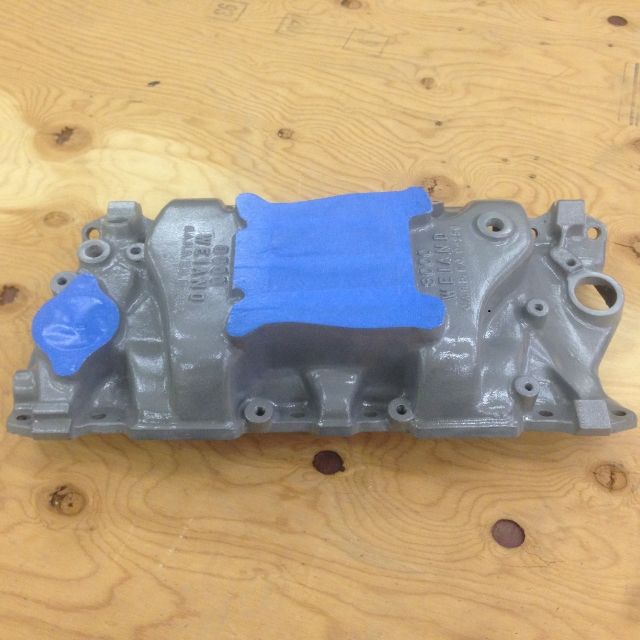

I've been picking away at the engine rebuild on my truck by spending an hour here and there when I can. It's kind of boring stuff to post on here but I've been working on reconditioning the non moving parts for the 283. My PO kindly drilled a hole in the middle of one of the original valve covers with a great deal of precision and care using what I can only presume was a dull pickaxe. But I found a different set on a 72 C10 at the junk yard last week ($5 each) so I yanked them and sandblasted them. I hammered out a couple small dings, and then applied a couple coats of Chevy Orange VHT Engine Enamel and they're as good as new. I got a used Weiand intake manifold on Craigslist for $30, sandblasted through 3 different colors of paint and then clear coated it, and I cleaned and sandblasted the timing cover with some more orange. The Oil pan is next.

Gotta watch the budget so I'm just waiting to get parts when I can. So far, Craigslist and junk yard finds have been successful. I got a pretty big sandblasting cabinet on Craigslist which came with a pressurized tank, a separate 40lb siphon tank, a small hand held mini blaster, and a brand new 40 lb jug of aluminum oxide for $100. I'll post some pics of my dust collection system too. I normally use it for woodworking at the shop but I connected it to the sandblaster cabinet and it works like a charm. Most of the media falls down into the bottom of the cabinet, but the fine dust gets sucked right out. Even after a couple days of sandblasting, the shop has no (new) dust on anything. Here's the Sandblasting Cabinet and Dust collector:  I drilled a 4" hole in the top of the sandblast cabinet, and then a smaller 2" hole on the back to create a place for air to enter. The clean air comes directly across the viewing window and picks up the fine airborne dust inside the cabinet. Then it goes directly through a cyclone filter which normally filters out the larger sawdust (or in this case, sandblasting media that happens to get sucked up). I wasn't happy with the fine dust that used to blow by the cyclone so I added a water filter stage. There are no paper filters in this system but the air that comes out has no dust left. I never lose suction in the system and I only have to empty the catch basin once every couple months if I'm doing a bunch of woodwork. Weiand Intake:  Valve Covers wet sanded once:  Timing Cover:

|

|

|

|

|

| Bookmarks |

|

|