|

|

|

#326 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

yeah. I'm going to adapt the rsx gauges to fit this panel yeah. I'm going to adapt the rsx gauges to fit this panel

|

|

|

|

|

|

#327 |

|

Boss Hogg

Join Date: Apr 2002

Location: The Beaver State

Posts: 2,361

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

*****in !

Can't wait to see more!

|

|

|

|

|

|

#328 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Some REAL pics of REAL work

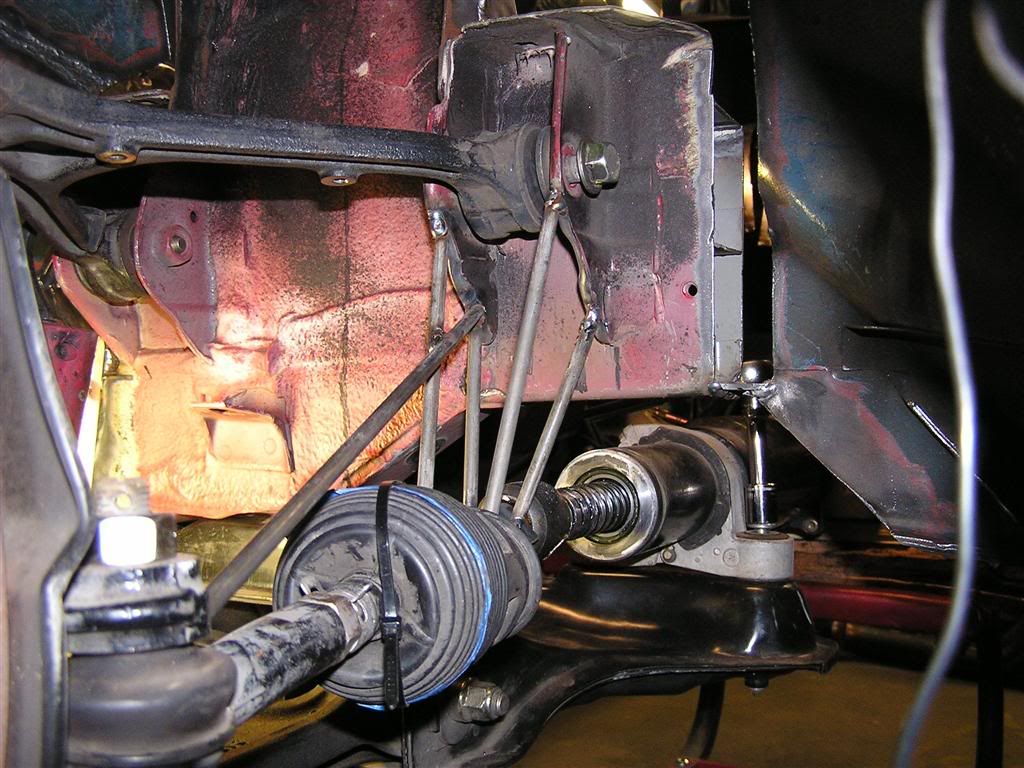

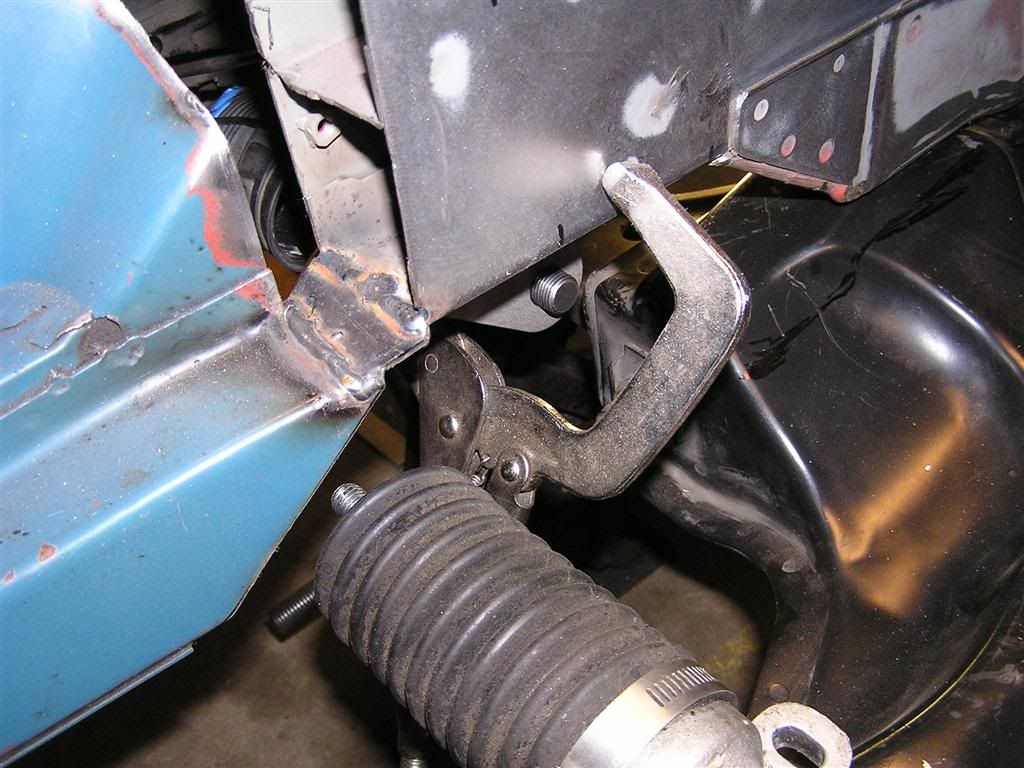

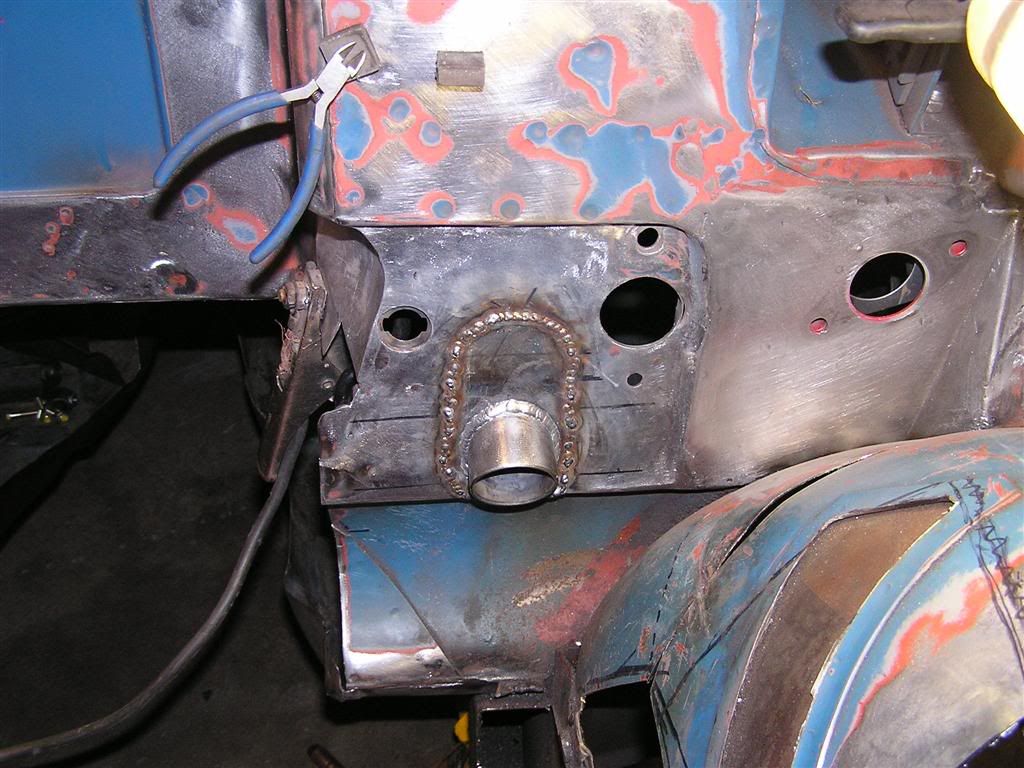

The steering column/firewall pass-through I'm working on. The tubing ID matches the column OD:  The S2000 R&P mocked into place to determine tie-rod placement:   Built a jig to allow me to duplicate factory tie-rod geometry when I install the new rack:     Rack removed:

|

|

|

|

|

|

#329 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

With the tie-rod removed from the rack, I added another reference bracket to the inner ball joint (a 4-link bracket I had on a shelf):

Here's the Triumph rack. I've fitted some bolts in place of the tie rods:  The S2000 shaft, and joints are on for a test fit. I may use them.  Just a very rough placement of the TR7/8 rack to show the offset between the rack output and the factory S2000 tie rod location. For those who didn't read the whole thread; the crank pulley is to far forward thus the rack must move forward. With a little inventiveness I should be able to retain proper tie-rod positioning while gaining the needed engine clearance. More to come on that:

|

|

|

|

|

|

#330 |

|

Under Construction

Join Date: Oct 2007

Location: Midlothian,TX (DFW)

Posts: 4,555

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Looking good Mike!

__________________

Heath subscribe to the board here: http://67-72chevytrucks.com/vboard/payments.php http://67-72chevytrucks.com/vboard/s...d.php?t=157669 FAQ how to's 1956 Chevy Apache 1967 C10 SWB FleetSide (under construction) 1969 K10 SWB FleetSide (Future Build) 1972 C10 SWB Stepside (Future Build) 56 chevy truck : http://www.cardomain.com/ride/2955823/1 67 truck build: http://www.67-72chevytrucks.com/vboard/showthread.php?t=281357/1 69 k10: http://67-72chevytrucks.com/vboard/s...d.php?t=389470 |

|

|

|

|

|

#331 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

I welded in the column passthru today. Stitched up the DS inner fender too. Started reinforcing the PS frame rail. But what took the most time was figuring out what tie-rod arrangement to go with. I got to know two very thick MOOG catalogs quite well today (thanks again Vern). So more parts are heading this way

|

|

|

|

|

|

#332 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

One of the side projects that's been holding up progress on the Minx is my "Mini Shop." It's about a 10x15 (if that) building that had been left unused for about ten years. After cleaning it out and fixing a broken window I decided to move in

It's a perfect place for the tube bender, air compressor, Blasting cabinet, and powder coating oven. It's a perfect place for the tube bender, air compressor, Blasting cabinet, and powder coating oven.So I rented a trencher and buried some 3/4" pex and 10ga 3 core wire to run 220 out there. The pex and all the push-lock fitting are awesome for this. Here's what I've done so far. Now back to the car! (just some bad cell phone pics):

|

|

|

|

|

|

#333 |

|

Registered User

Join Date: Mar 2008

Location: Waukee, Iowa

Posts: 1,608

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

What size compressor is that? I'm assuming you did your research first, but that 10ga seems a little light. A buddy burned up the motor on his compressor powering it with 10ga. wire. Seems like the IR book for mine said 6ga...so that's what I ran on a dedicated circuit for it (7.5hp).

__________________

build threads: 86 Suburban 88 Jeep 6.0 swap 49 Chevy truck 54 Chevy wagon 86 Suburban lowered 4/6 54 Chevy wagon 49 Chevy/s10 mix 88 Jeep Wrangler rockcrawler |

|

|

|

|

|

#334 | |

|

Boss Hogg

Join Date: Apr 2002

Location: The Beaver State

Posts: 2,361

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Quote:

Just thought I should mention also, it should be 4-wire for a subpanel. |

|

|

|

|

|

|

#335 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

You know, now that you mention it I think I went with 8 gauge copper. I'll have to check again. I remember seeing that it was good for 40A. Yes it is 4-wire and I installed a sub panel. In fact I installed a ground rod too. The compressor draws a max of 21A (5hp).

|

|

|

|

|

|

#336 |

|

Boss Hogg

Join Date: Apr 2002

Location: The Beaver State

Posts: 2,361

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Awesome. I saw the panel to the left of the blast cabinet in the photos. And an oven should be less than 40A. I would run either a 30A or 40A circuit to most wall ovens(not ranges-those are 50A). So as long as they are not on together you should fine.

|

|

|

|

|

|

#337 |

|

Registered User

Join Date: Jun 2006

Location: Indiana

Posts: 4,859

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Just my .02, but I would lift the stove top and unplug the top burners.

An ounce of prevention ya know. Maybe you already have. It is hard to see under the table.

__________________

'70 GMC C1500 LWB Power disc brakes. WooHoo! Posi 6 Lug Dana 60 Last edited by ERASER5; 11-21-2009 at 02:52 PM. |

|

|

|

|

|

#338 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Burners are removed. Kids love to turn knobs. Thanks for lookin out guys

|

|

|

|

|

|

#339 |

|

the pollock

Join Date: May 2008

Location: abilene, texas

Posts: 4,423

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

YOU make me feel small inside....

ha ha ha

__________________

Jack of ALL trades, Master of none.. (but one... procrastination) Army vet 02-08 RIP El Jay! Miss you brother! http://67-72chevytrucks.com/vboard/s...d.php?t=343538 http://67-72chevytrucks.com/vboard/s...d.php?t=386042 |

|

|

|

|

|

#340 |

|

Registered User

Join Date: Dec 2008

Location: on a rock in the pacific

Posts: 554

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

lookin good FF. wanted to ask what the PEX is? is it that white line from your water trap? how much is is per foot in your neck of the woods? what PSI can it handle? looks flexible and something i might be looking at for my shop. i like your copper "cooling loop". i have soldered a whole bunch of copper tubing up to make a radiator to the same effect for my compressor. just wish that when i bought mine, the newer model was out. same price, 15 gallons more. oh well cant' win them all.

__________________

63 4 door Chevy II - NOVACATION (Updated 08/23/09) 65 Morris minor Traveler 77 Chevy Longbed. 93 Corolla JDM 20V Swap Daily Driver (Updated 07/16/09) Powder coating Hawaii Domestic Violence Awareness Show 5/3/09  Hawaii Rod and Custom Show 4/18 Hawaii Rod and Custom Show 4/18

|

|

|

|

|

|

#341 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Yes, it is that white line after the water trap. I kept that service loop since that's the buried line. Here's a link to some info on PEX.

It is generally used for water plumbing and radiant floor heating. But it can be used for low pressure air as well. The 3/4" tube I used is spec'ed out for 160psi at 70* and gets lower as temp increases. I'm regulated down to 90psi right off the tank so I'll never come close to 160. Can't remember the exact price but I think it's around 40-50 cents a foot in 3/4". The fittings aren't cheap either but the install was so fast and easy, not to mention expandable, flexible, easy to work with; it is well worth the money IMHO. |

|

|

|

|

|

#342 |

|

Registered User

Join Date: Dec 2008

Location: on a rock in the pacific

Posts: 554

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

thanks for the info on the PEX. better alternative to what i was planning to use.

man FF, the more i look at your shop and mini shop, you really got a good deal on that property. i'm wondering if you have a barn stashed on the other end of the property. wish i could score a place like that. sweet...

__________________

63 4 door Chevy II - NOVACATION (Updated 08/23/09) 65 Morris minor Traveler 77 Chevy Longbed. 93 Corolla JDM 20V Swap Daily Driver (Updated 07/16/09) Powder coating Hawaii Domestic Violence Awareness Show 5/3/09  Hawaii Rod and Custom Show 4/18 Hawaii Rod and Custom Show 4/18

Last edited by Jvsapp; 12-02-2009 at 04:26 AM. |

|

|

|

|

|

#343 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Yeah, I know it was quite a score. Right place at the right time for once

The house needs a remodel and you know I have some ambitious plans there, but it's very livable as-is for now. It's also 2.5 miles from the largest employer in town (Intel, where I work), and even closer to Costco (but not too close). Yet it feels like a very rural property. The house needs a remodel and you know I have some ambitious plans there, but it's very livable as-is for now. It's also 2.5 miles from the largest employer in town (Intel, where I work), and even closer to Costco (but not too close). Yet it feels like a very rural property. No barn  ...and no garage to park the drivers in. It does have a big carport that the 64 lives under. That will become a garage in time though ...and no garage to park the drivers in. It does have a big carport that the 64 lives under. That will become a garage in time though  Off to the shop!!! Last edited by Frizzle Fry; 12-03-2009 at 12:31 AM. |

|

|

|

|

|

#344 |

|

Registered User

Join Date: Dec 2008

Location: on a rock in the pacific

Posts: 554

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

dang you work for intel? had i stayed @ devry i'd probably have wound up there too. but your shop and mini shop would be an instant buy for any gearhead. the wife can have the house, i'd take the shop and mini shop and be willing to do any repairs to make the house work for her

my old man setup my moms place pretty good before he passed. the garage is 25X60 and i also have a 10X30 corrugated galvanized shop in the back yard. my blast cabinet and compressor are back there with the oven. i thank him for that, but i just gotta convince the mom to let me keep my toys there and bring more back. hopefully one day that place will be mine. hmm thinking of that i should post pics of my shop.... maybe we should start up a post your shop thread? or is there one already? anyways back on subject. where's the updates of the minx

__________________

63 4 door Chevy II - NOVACATION (Updated 08/23/09) 65 Morris minor Traveler 77 Chevy Longbed. 93 Corolla JDM 20V Swap Daily Driver (Updated 07/16/09) Powder coating Hawaii Domestic Violence Awareness Show 5/3/09  Hawaii Rod and Custom Show 4/18 Hawaii Rod and Custom Show 4/18

|

|

|

|

|

|

#345 |

|

Boss Hogg

Join Date: Apr 2002

Location: The Beaver State

Posts: 2,361

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Updates?

Last edited by Sub-versive; 12-04-2009 at 01:48 AM. |

|

|

|

|

|

#346 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

I was waiting to have a bit more done but at the rate I've been working lately I might as well...

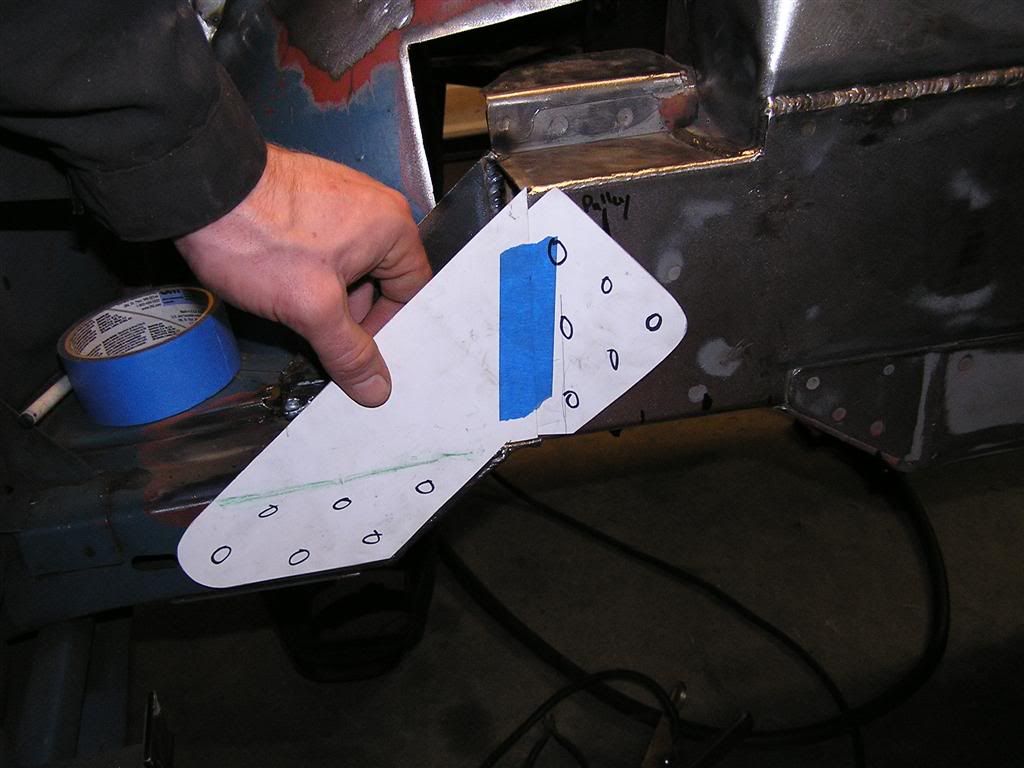

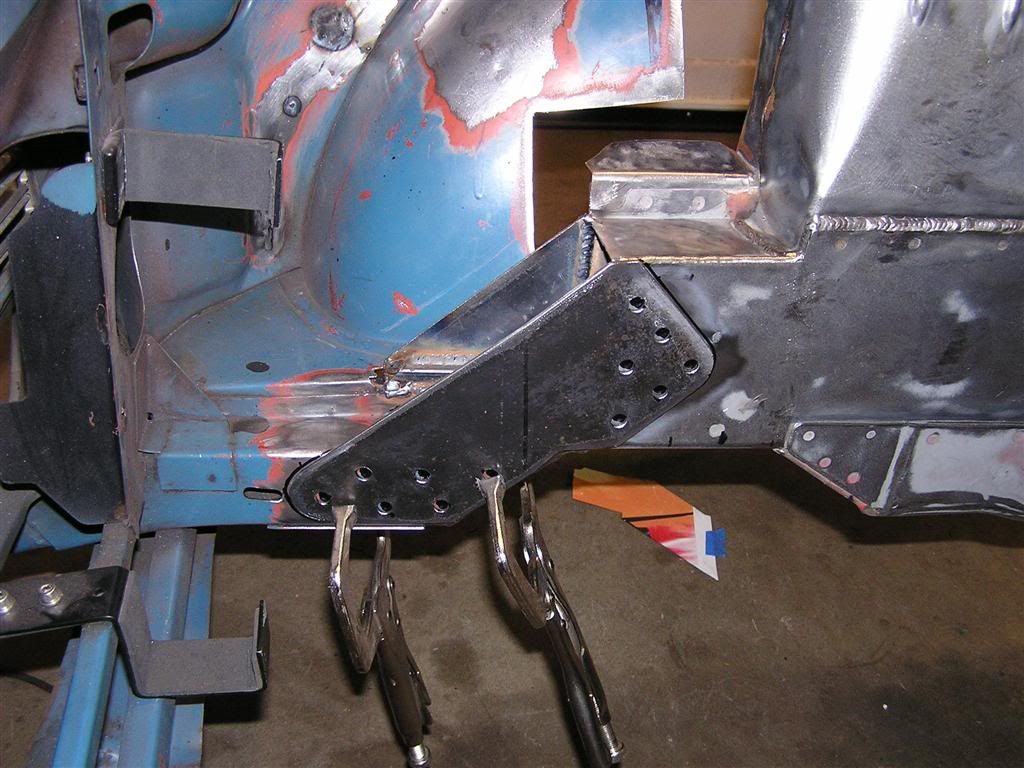

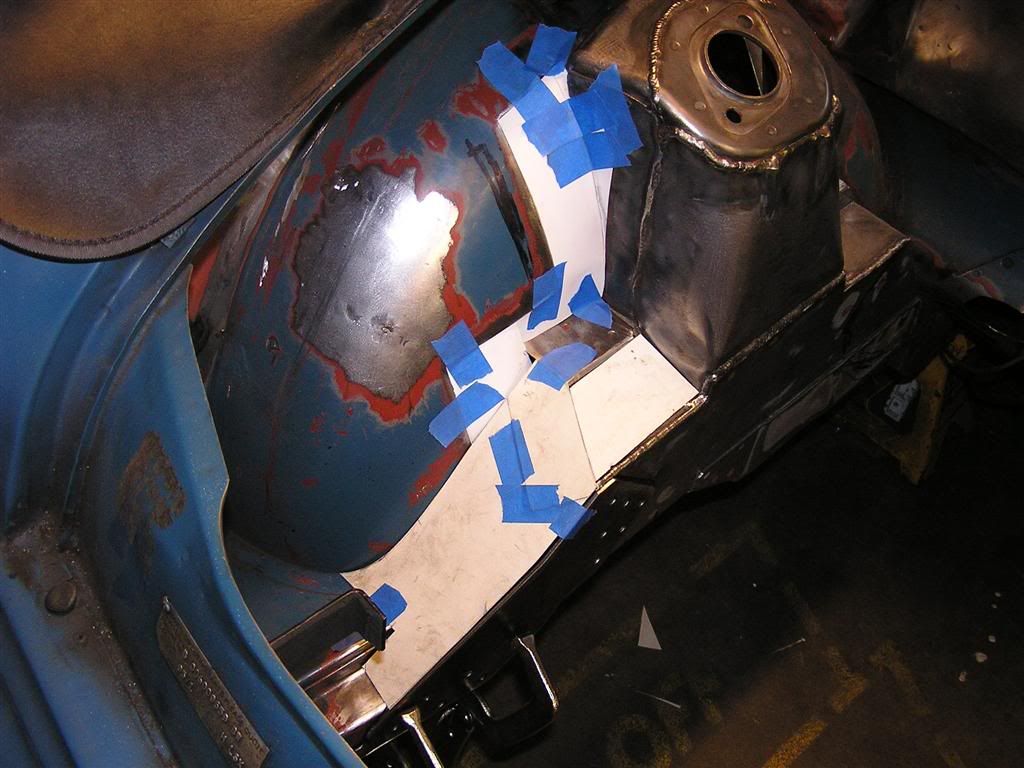

First of all this is required before any work begins these days:  and here's the column passthru (will clean up):  Boxing the frame rail in. This outer piece sits on the frame rail's lower edge (rail has a lip that extends out). Because of that lip it does not sit against the upper edge of the rail. This was the solution:    Inner plate template:  and in metal:  Top Plate:   and more templates to fill all those gaps:  That's it for now. Believe it or not; those templates can take some time to make. But the better they are, the less work required to make the real thing fit. Plus I should be able to use them again on the other side. Last edited by Frizzle Fry; 12-04-2009 at 05:55 AM. |

|

|

|

|

|

#347 |

|

Registered User

Join Date: Mar 2008

Location: Waukee, Iowa

Posts: 1,608

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Frizzle, since all your projects seem to be grafting all sorts of sheetmetal together in different configurations, how do you address the metal shrinking at and around the weld? Do you hammer them out to try to flatten them, or what advice can you give? Last weekend I experimented with grinding my welds down with the edge of a .045 cutoff wheel, and then finishing them out with a flap disc and noticed that using the edge of the cutoff wheel resulted in significantly less heat than a grinding wheel, in fact by the time I put the grinder down I could touch the area I just ground...but I still noticed the metal shrinking some.

I was splicing 2 bed floors together, so the shrinking really doesn't matter much...but here is where I'd like to learn before moving on to exterior panels.

__________________

build threads: 86 Suburban 88 Jeep 6.0 swap 49 Chevy truck 54 Chevy wagon 86 Suburban lowered 4/6 54 Chevy wagon 49 Chevy/s10 mix 88 Jeep Wrangler rockcrawler Last edited by BlueJeep; 12-04-2009 at 11:23 AM. |

|

|

|

|

|

#348 | |

|

Enjoying left field

Join Date: Jun 2008

Location: Dillon Montana

Posts: 900

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Quote:

|

|

|

|

|

|

|

#349 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

I don't seem to get shrinkage from grinding. Maybe I use less pressure. I have been taking the welds down to near-surface level with a grinding wheel, then hitting them with the flap disc, then 80 grit DA.

The key to avoiding warpage starts with the weld itself. On thin stuff I tac-tac-tac, jumping around to avoid too much heat in one area. It ends up looking like the steering column pass-through pic in my previous post before grinding. Not the prettiest to look at but it all gets ground smooth anyway. |

|

|

|

|

|

#350 |

|

Registered User

Join Date: Dec 2008

Location: on a rock in the pacific

Posts: 554

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

i've used roloc disc to gently take the metal away when i do some grinding. i've used the cut off wheel technique too, but flap or grinder to knock most of it down, then i use roloc red or brown to smooth it out. i've really been pleased with how it comes out.

__________________

63 4 door Chevy II - NOVACATION (Updated 08/23/09) 65 Morris minor Traveler 77 Chevy Longbed. 93 Corolla JDM 20V Swap Daily Driver (Updated 07/16/09) Powder coating Hawaii Domestic Violence Awareness Show 5/3/09  Hawaii Rod and Custom Show 4/18 Hawaii Rod and Custom Show 4/18

|

|

|

|

|

| Bookmarks |

|

|